The SF6 Circuit breaker is a compact device that uses sulfur hexafluoride gas to quench the arc during its operation, i.e, to break or make a medium to high voltage electric circuit. Along with the protection system employed in the circuit, this circuit breaker operates, and the contacts open, to isolate the faulty circuit. Or, after the maintenance of the circuit, closing of this breaker’s contact charges the electrical circuit for power transmission and distribution.

Table of Contents

Why is SF6 gas used in Circuit Breaker?

SF6 gas has exceptional thermal and electrical properties, which make it an excellent choice for the arc quenching medium and hence extensively used in an SF6 circuit breaker.

Dielectric strength: The dielectric strength of SF6 gas is 2.5 times that of air. Therefore, the electrical insulation in high voltages is better than that of air. Since the insulation is the primary factor that impacts the equipment size, compact designs are possible with SF6 breakers.

Arc Quenching ability: In SF6 circuit breakers, arcs form during contact separation. The SF6 molecules catch the free electron, absorbing it to deionize the environment inside. This makes the extinguishing of the arc faster and better than that with air or oil.

Thermal capacity: The SF6 gas has good thermal conductivity, with volumetric heat absorption ranging from 3.5 to 3.8 times that of air. This makes it an excellent fluid for heat transfer as it provides a cooling effect to the plasma and efficiently dissipates the arc energy.

Non-flammable: Because the S-F bonds have high energy, and the steric hindrance of 6 fluorine atoms surrounding a sulfur atom prevents it from reacting. This makes SF6 chemically stable and non-flammable.

Low maintenance: Being chemically stable, SF6 gas does not deteriorate quickly, demanding less maintenance and servicing. The frequency of gas charging is also less in comparison to others.

Construction of SF6 Circuit Breaker

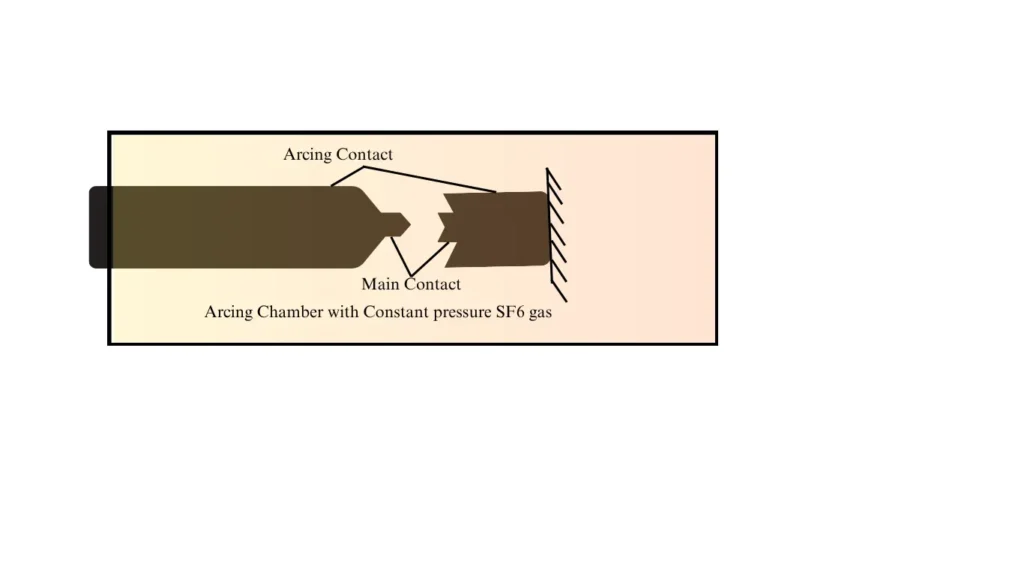

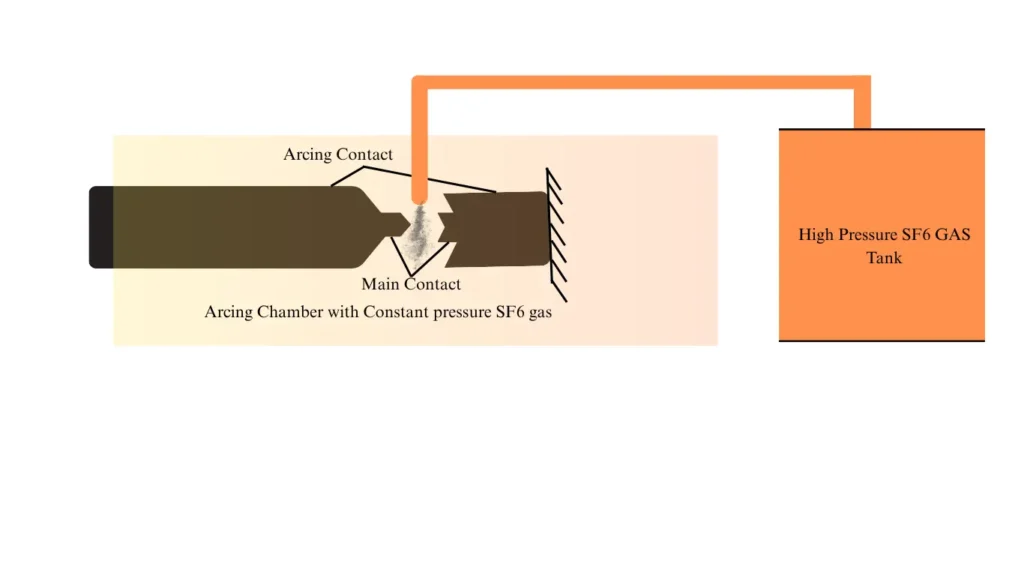

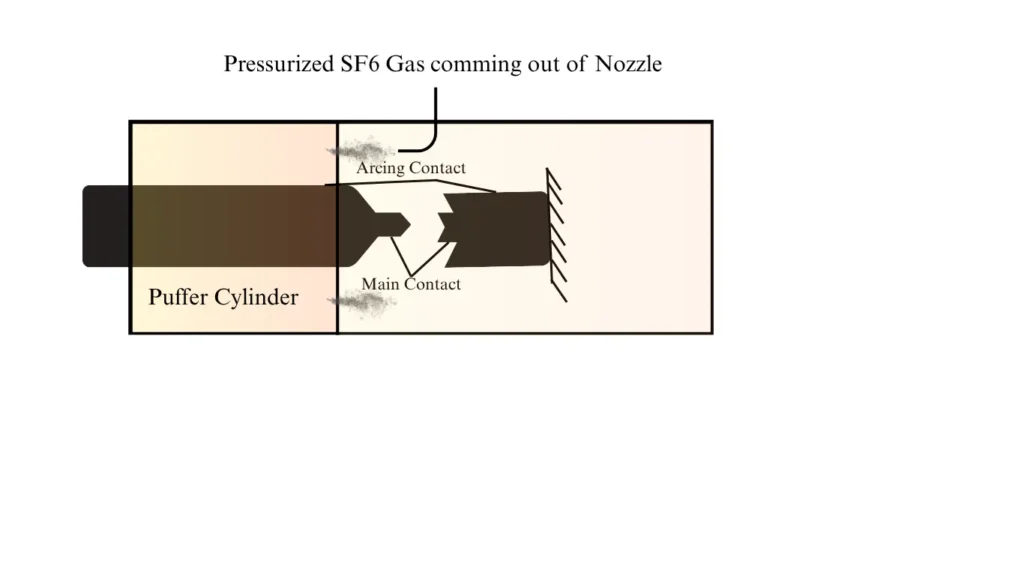

Contacts: The main contacts of the SF6 circuit breakers are usually made up of copper alloy (copper-tungsten or copper-chromium), which ensures high electrical conductivity, while the arcing contact is made of tungsten-copper alloy, as it ensures a very high melting point, which is necessary as the heat from the arc is very high. These contacts are also erosion-resistant.

The main contacts carry the rated current during normal operation and have very low resistance. The arcing contacts open first, diverting the arc to them, thus saving the main contacts from the heat and erosion from the arc. Periodic inspection and replacement of the arcing contacts may be needed as the arcing contacts erode over time because of the arc, but the interval is very high compared to other types of circuit breakers.

Utilizing the design of keeping the main contact away from the conduction of heat and subjecting the arcing contacts to the arc, SF6 circuit breakers are able to achieve longer life, high reliability, and reduced maintenance.

Arc Chamber: The arc chamber of an SF6 circuit breaker is the closed space where the contact separates and an arc is formed in the process. The chamber is filled with SF6 gas, which provides electrical insulation as well as the medium for quenching of the arc. The chamber is mainly to restrict the arc within itself and direct the SF6 gas to the arc for effective cooling, deionization, and extinction.

The chamber has insulating nozzles to guide the SF6 gas and is made to withstand high temperature and pressure. The arc chambers are hermetically sealed to prevent leakage of SF6 gas. The arc chambers of SF6 circuit breakers are more compact than oil and air circuit breakers and offer faster arc extinction even at fault currents that are significantly higher.

Operating mechanism: The operating mechanism of an SF6 circuit breaker is mostly spring or hydraulic-operated. It provides the necessary force to open and close the main contacts of the breaker.

The spring charging mechanism utilizes a mechanical spring, which stores the required energy. When triggered, the stored energy is released and utilized to move the contact. After the operation of the breaker, the spring is stressed back to its original position by hand or by motor operation. This system is more advantageous as it requires less maintenance and is quieter than a hydraulic system, used for medium voltage applications, as the energy storage capabilities are limited.

The hydraulic mechanism utilises fluid stored in a tank, as the hydraulic piston moves with the operation of the control valve, displacing the oil/hydraulic fluid, forcing the opening/closing of breaker contacts. This system is preferred for HV and EHV applications where the force required is high. The hydraulic system can provide high-pressure density utilised in the operation of breakers with high fault current capabilities. The operation is smooth and fast, yet complex and costly than the spring mechanism and requires high maintenance.

Gas system: The SF6 circuit breaker operates on a closed gas system. The gas is reused for continuous normal operation, sealed inside the breaker without any release to the atmosphere, which reduces environmental impact and saves the cost of gas. The SF6 circuit breaker is equipped with a gas density monitor, since the density depends upon gas pressure, the gas density monitor shows the gas pressure inside the breaker.

These breakers indicate low pressure in the control panel of the breaker to alert the operator, and also have a lockout function, which prevents the breaker operation when the gas pressure goes below safe levels. This is because at low gas pressure levels, the gas density is low, and proper electrical insulation will not be present, and also arc interruption will not be proper because of low gas pressure, which can deform the main contacts due to heat and deform the interrupter unit.

Porcelain/Epoxy housing: This houses the interrupter unit and provides insulation between the live and earth/structure of the SF6 circuit breaker. Besides electrical insulation, it provides mechanical support to the interrupter unit and helps withstand the internal pressure during operation.

Types of SF6 Circuit Breakers

Single pressure type: The single pressure type breakers utilize constant gas pressure that is built inside the gas chamber. During contact separation, an arc is formed, which is deionized and quenched in the constant-pressure SF6 gas. It is simple in construction and can be used up to 245 KV voltage levels.

Double pressure Type: These types of breakers usually have a separate gas chamber for the main and arcing contact and one for the insulation. During the operation of the breaker, high-pressure gas is released from the gas chamber, which forces the arc to extinction with gas blasts. These types of breakers are best suited for high voltage applications with high current breaking capability and are more complex compared to the single-pressure type.

Puffer type: In this type of circuit breaker, there is a fixed volume of SF6 gas inside a cylinder. As the moving contact separates, it pressurises the fixed gas volume. This puffed gas or pressurised gas is forced to the arc via nozzles, which deionizes the environment inside and extinguishes the arc. These breakers are widely used for medium to high voltage applications because of efficient arc quenching and simple mechanics. As the movement of the moving contact controls the flow of gas and thus pressure, these breakers can handle high short-circuit currents.

Self-blast type: These breakers use arc energy along with gas flow dynamics to extinguish the generated arc. When the arc is formed, the SF6 gas expands slightly because of the heat. This expansion generates pressure in the system, and when passed through the nozzle, it forms a high-speed flow of the gas that blows out the arc. These breakers are suited for EHV applications. Although the construction is complex, the design is still compact. The gas system requires regular monitoring.

Application of SF6 Circuit Breakers:

High Voltage application: SF6 circuit breakers are used extensively for switching operations of high voltage transmission lines, power transformer bays, indoor and outdoor substations, ranging from 33 KV to 800 KV because of their excellent arc quenching capability and compact size.

Industrial power system: These circuit breakers are used in industrial applications because them being extremely suitable for high voltage and high current applications and isolate critical machines and processes during short circuit and overloading.

Renewable energy: SF6 circuit breakers are widely used in renewable energy plants because of their long life and low maintenance.

Railway Traction Substations: These are extensively used in the railway traction substation for reliable switching operation of the railway traction lines.

Data center: It provides reliable switching in high voltage data center substation, and because of its long life and compact design, it is chosen for service.

This article is a part of the Switchgear, where other articles related to switchgear are discussed in details.