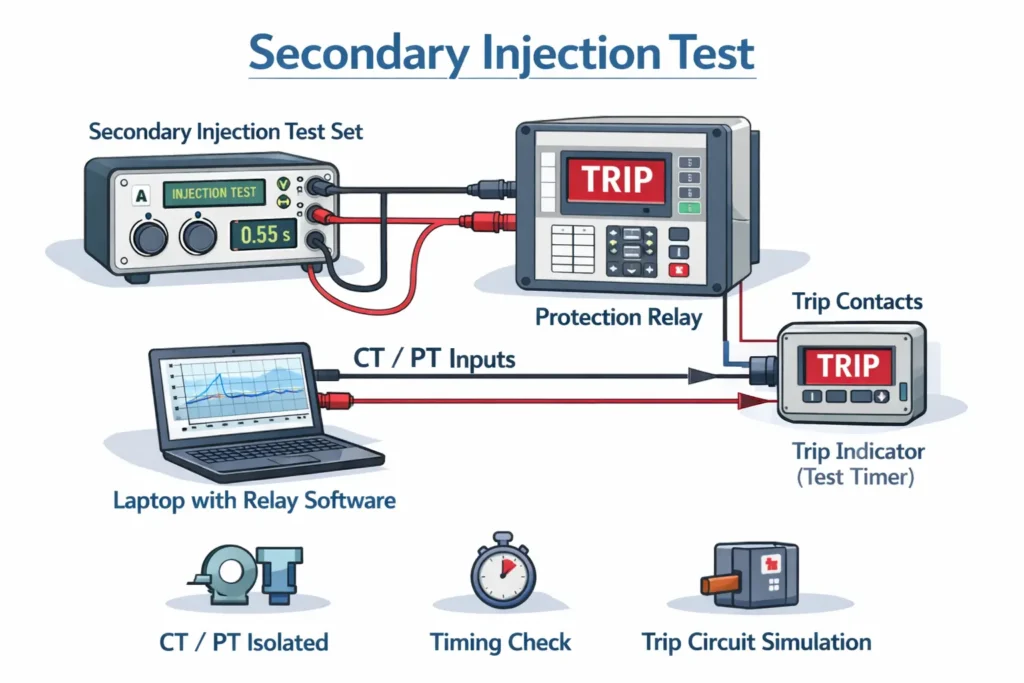

Secondary injection test is a controlled process of verifying the correct operation of protection relays and associated control circuits without energizing the primary power equipment. In the secondary injection test, a calibrated test kit injects low level current and voltage signals directly into the relay’s secondary terminal, simulating the fault and load conditions that would normally be produced by current transformer and potential transformer. In secondary injection test, since, the primary circuit remains isolated, the test becomes inherently safe, repeatable, and suitable for commissioning and routine maintenance.

The secondary injection test allows the engineers to confirm relay pickup values, time-current characteristics, logic schemes, interlocks and tripping outputs in accordance to design setting and protection philosophy. This is very useful for numerical and microprocessor-based relays where complex algorithm and communication logic must be validated. Although, secondary injection test does not assess the health of the primary equipment like current transformers and circuit breaker, it is essential to ensure the response of the protection system under actual fault conditions.

Table of Contents

Working principle of Secondary Injection Test

The secondary injection test works on the principle of simulating the power system fault condition by injecting controlled electrical quantities directly into the secondary circuit or input terminals of the relay. Instead of energizing the primary equipment, a secondary injection test kit supplies precisely adjustable current and voltage signals to the relay input terminal, representing the output of CT and PT simulating normal and fault conditions.

By gradual increase in current or voltage, the relay’s pickup threshold is identified. Further variation of the injected quantities allows verification of operating time, time-current characteristics, directional logic and protection function like over current, earth fault, differential, or distance protection. The relay processes these injected signals exactly as it would, in case of actual system disturbance.

As the injected quantities exceeds the preset settings, the relay operates and issues trip or alarm commands, which is observed through relay indication, output contacts, or breaker trip circuit. Thus, the secondary injection test validates the protection system relays without involving high current, high voltage or primary system components.

Secondary Injection Test Kit

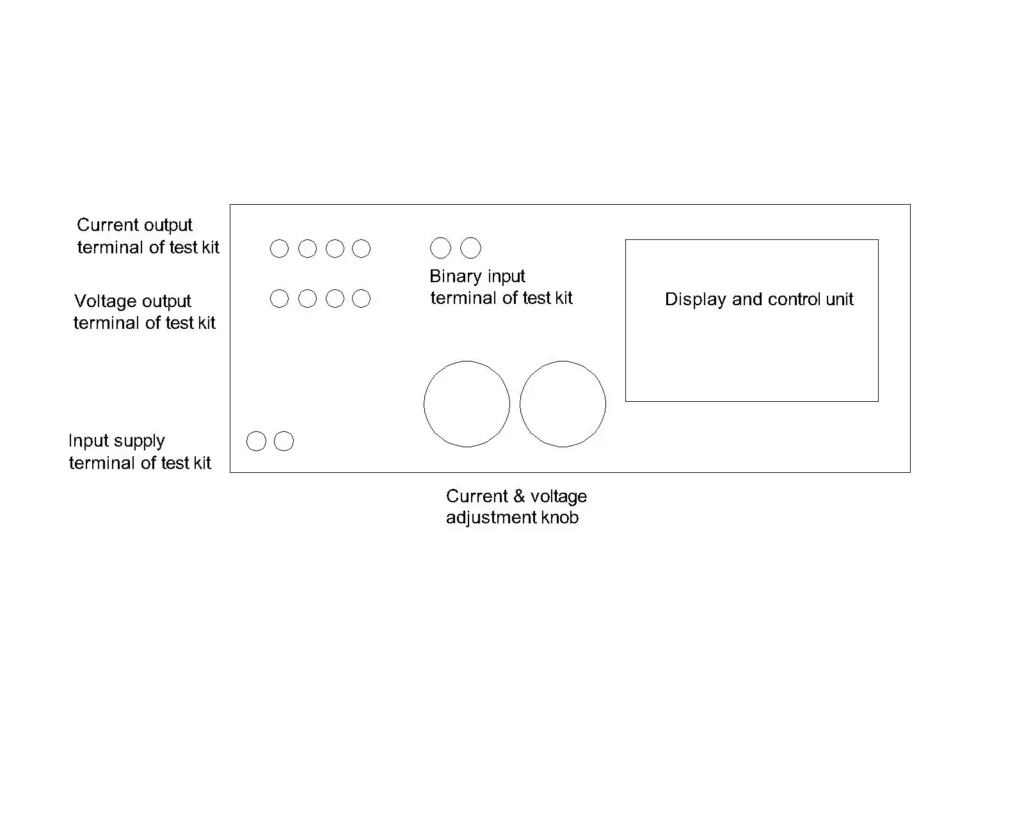

A secondary injection test kit is a portable testing device used to evaluate the performance of the protection relays by injecting simulated current and voltage signals directly into the secondary circuits. It consists of highly accurate voltage and current sources capable of generating adjustable AC output over a wide range and DC output. The kit is integrated with computer-based control system which allows precise variation of magnitude, phase angle, frequency, and timing of injected signals. Using dedicated software, test sequence can be automated and relay response can be monitored in real time. The results can be recorded for analysis and documentation during commissioning and maintenance.

Modern secondary injection kits have independent 3 phase current and voltage outputs, however, the older kits have single phase outputs and requires multiple tests to cover all phases. The response of the relays is also taken in the test kit via the binary input terminals.

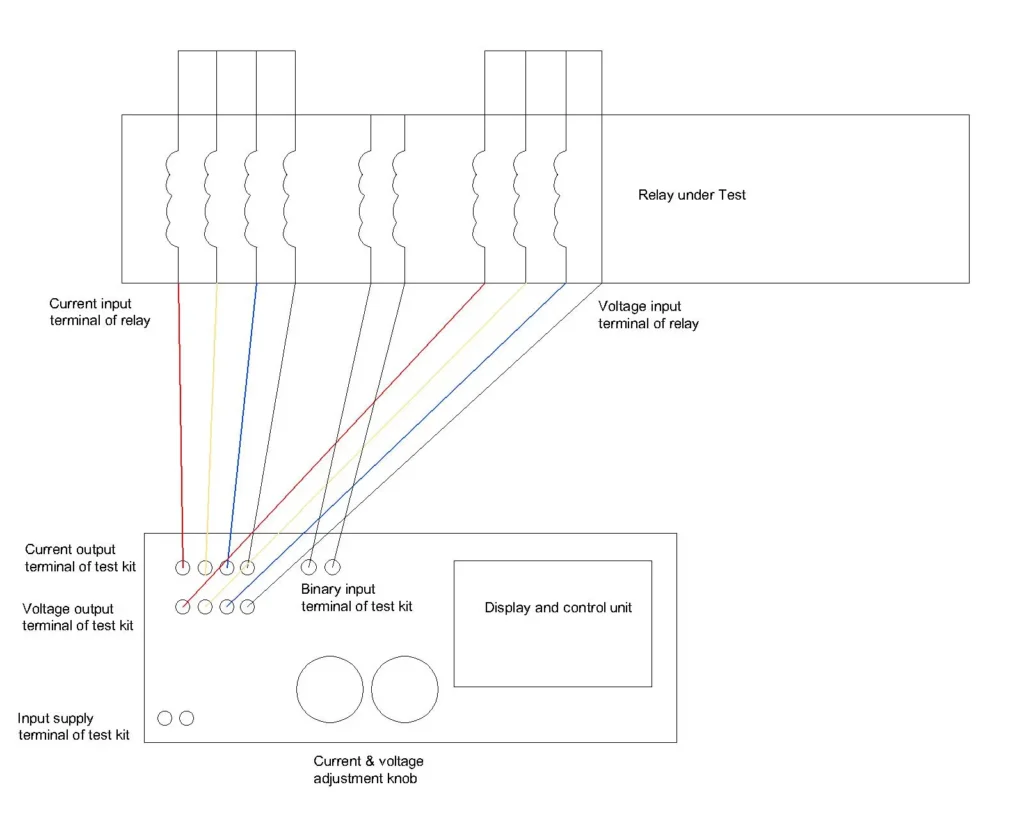

Test connection

During the secondary injection test, the test kit which has the voltage and the current source is directly connected to the relay input terminals. The three phase current output R,Y,B and N is connected from the kit to the relay terminal or relay block via the current leads. Similarly, three phase and neutral voltage output from the kit is connected to the relay’s voltage input terminal via voltage lead. A DC auxiliary supply is provided either from the test kit or from substation DC battery system to energize the relay under test. The binary output from the relay (trip and alarm) is connected back to the test kit to monitor operation, timing and contact response accurately.

Test procedure

Step 1: Isolate the bay whose protection is to be tested form live system and then isolate the protection relay from the actual circuit to prevent unwanted operation during testing. Ensure all safety precautions are in place.

Step 2: Connect the secondary injection kit to the relay’s current and voltage terminal using appropriate test leads and plugs as per the intended wiring diagram.

Step 3: gradually inject the current and or voltage from the test kit to determine the relay’s pickup value. Slowly reduce the injected quantity to observe the drop off value of the relay.

Step 4: Inject predefined fault quantity to measure relay operating time and verify the time-current characteristics against the setting of the relay.

Step 5: Verify the correct operation of relay output contacts, tripping logic, alarm and indications.

Step 6: After the test is conducted, reset the relay, remove the test connection and restore normal wiring and service condition.

Parameters verified during the test

During secondary injection test, several critical protection parameters are verified which ensures the reliable performance of the protection relay which is under test. The relay pickup and drop off accuracy is checked by gradually varying the injected current or voltage to confirm that the relay operates and resets precisely at the set values, thus ensuring sensitivity without nuisance tripping.

The time delay or the operating time of the relay is measured by injecting the fault quantities above the pickup level and recording the elapsed time until relay operation. This verifies the compliance of the relay with definite time or inverse time characteristics. The correct logic and characteristics curve are verified by simulating different fault condition and checking the relay follows the programmed protection logic, coordination scheme and time-current characteristics as per settings.

Finally, the trip and alarm contact operation is confirmed by observing the relay binary output contacts ensuring correct signaling and breaker command initiation.

Acceptance criteria

As per IEC 60255, the pickup current of the relay shall be within permissible tolerance defined by the standard or manufacturer which is typically within ±5% of the set value for numerical relays. The measured operating time shall conform to the selected definite time or inverse time characteristics within allowable error limits as specified in IEC 60255-151 which is ±5% or ±20 ms whichever is greater. For example, if the set time is 1 s (say), then permissible range for operating time is 0.95s to 1.05 s.

The relay shall exhibit no spurious operation when injected quantities are below pickup level or during stable condition. All the indication, alarm and output contacts shall operate correctly, consistently and in accordance to the programmed protection logic.

Reference

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.