A disturbance recorder is a component of the digital fault recorder installed inside the intelligent electronic devices IEDs of the substation. It is used to capture high resolution electrical waveforms and digital status of various components connected to the system, time stamped during transient events or abnormal conditions caused due to electrical faults.

Unlike a energy meter or substation SCADA, a DR records voltage and current waveforms, sampled at rate of 1-10 KHz or sometimes higher. The disturbance recorder also records binary signals like relay pickup, circuit breaker status, and the output of the protection system. The disturbance recorder basically uses the GPS or NTP or PTP to sync the time and records the data with time stamps.

Table of Contents

Role of disturbance recorder in power system

Identification of fault type: The type of fault L-G or L-L or 3-phase fault is determined by analysing the phase voltage dips and identifying phase current surges.

For a single line to ground fault (L-G), the phase current will significantly increase while the corresponding phase voltage will drop with large magnitude of zero sequence current component present.

For a phase fault L-L the faulted phase’s current surges simultaneously and the voltages of the phases dips or collapses while the third phase remains unaffected or minor disturbance due to system coupling. From symmetrical component perspective, it contains only positive and negative sequence current components.

For a 3 phase fault all the phase currents will equally surge with equal drops in the phase voltage with absence of zero sequence current component.

Fault inception angle: This is the angle expressed is electrical degree (0-360°) at which the fault initially develops. It is found by looking into the first transient jump in the current waveform and then the time stamp is checked by comparing it with the voltage waveform just before the fault to confirm if the fault occurred at positive peak 90° or negative peak 270° or zero crossing 0° -180° or intermediate angle.

This is important because fault occurring at the voltage zero crossing results in large DC offsets, producing high asymmetric peak current. This increases the mechanical and thermal stress on the components of the substation like CT, CB, etc. While faults near the voltage peak gives minimal DC offset and the current waveform is more symmetrical.

Modern disturbance recorders calculate this angle using θ = 360° x (tfault-tzero cross)/T,where tfault is the fault inception time, tzero cross is nearest reference zero crossing and T is the fundamental time period 20ms for 50Hz system and 16.67 ms for 60 Hz system.

Estimating the fault location: For estimation of the fault’s distance, disturbance recorder’s report from both end substation is required and it can be found out by the following methods.

Using Reactance method, which is the most common method. The disturbance recorder records Vfault and Ifault at the measuring point typically the substation, during the fault. From these quantities the fault impedance is calculated. Z measured = (V/I) fault. This impedance represents the line impedance from the measuring point up to the fault.

The measured impedance has two components Z = R + j X. In practical faults, the fault resistance includes the arc resistance, tower footing resistance, ground resistance which significantly distorts the resistive component R. Hence, the reactance component is used for distance calculation as it is primarily determined by the line inductance and is unaffected by the arc resistance and increases linearly with the distance.

Distance = X measured / X line per unit length

In the travelling wave method the high frequency transient (travelling waves) created during the fault are used. By using the time synchronised disturbance recorders at both end of the line, the time difference (Δt) in the arrival of the travelling waves at each terminal is found from the disturbance recorder’s report. The fault location is calculated using the wave speed (v).

D = (L-v.Δt) / 2

Analysis of fault clearing time: The disturbance recorder’s binary channels are important to this analysis. These channel records the status of the protective device as ON and OFF signal.

The fault clearing time is the total time of the start of the fault as seen from the current and voltage waveform till the moment the circuit breaker’s auxiliary contact confirms the circuit breaker is open.

T Clearing = T CB open – T Fault start. This allows the engineers to break this down into relay operating time which is T Relay Trip Command – T Fault start and circuit breaker operate time which is T CB Open – T Relay Trip Command. This validation makes sure that the protection system meets the operating standard.

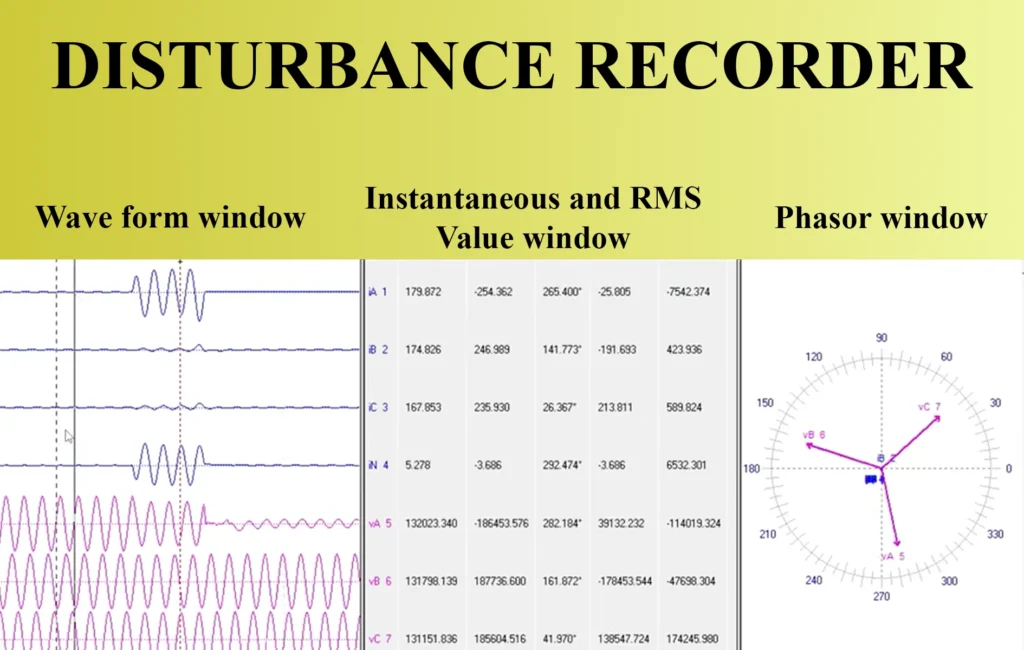

Wave from review: The wave form review answers various questions critical to the power system.

If the fault was external or internal?

If the fault is external or outside the protection zone of the relay, the current will increase and the voltage will dip but the relay wont trip as confirmed from the wave forms and binary records. When the fault is internal, it is characterised by correct trip signals issued by the local relays followed by opening of circuit breaker.

If the circuit breaker’s interruption was correct?

The wave form must show the fault current dropping to zero rapidly after the open command of the circuit breaker. The binary channel of the disturbance recorder confirms the opening of the circuit breaker as 52a contact changes state. If the current persists or attempt to flow again after the breaker is open, it suggests a issue with the breaker.

Restrike or delayed clearing?

If the fault current flow continues beyond the expected tripping time, typically 3-8 cycles, it indicates a breaker failure or relay malfunction.

A restrike is basically the reignition of arc after the first initiation of the circuit breaker to interrupt the current. It happens during switching of capacitive loads such as a capacitor banks or a long unloaded line. The current and voltage wave-form from the disturbance recorder will show a sudden high frequency, high magnitude transient indicating the arc has been re-established across the open breaker contacts.

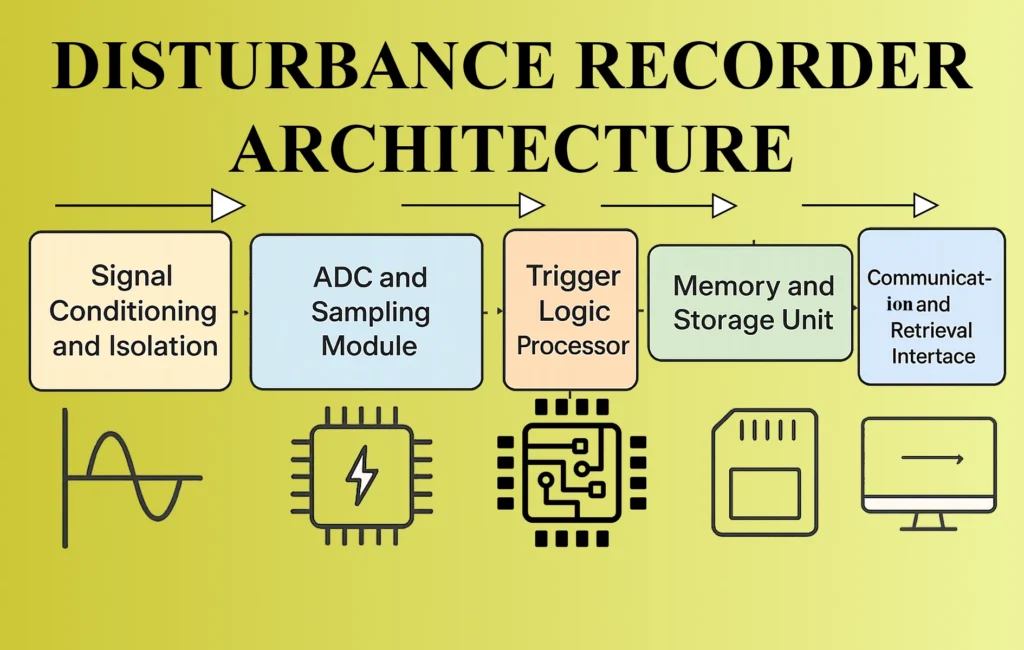

Architecture of the disturbance recorder

Signal conditioning and isolation: The input signal interfaces directly from the secondary of the CTs and PTs. The raw signal is scaled to internal level by using precision attenuators and burden resistors. Electrical isolation is achieved by using isolation amplifiers to protect the internal electronics from high transient overvoltage and antialiasing filters are also added to remove the high frequency noise.

ADC sampling module: The analogue signals are fed to high resolution ADC of the disturbance recorder. Modern disturbance recorders uses simultaneous sampling ADC to ensure phase accuracy between channels which is essential for sequence components and impedance calculations. The sampling rate is much higher which allows the disturbance recorder to record fast transient, DC offset and sub cycle phenomena. The samples are time stamped using internal clock which is synchronised via GPS or NTP.

Trigger logic processor: It continuously monitors the incoming samples in real time. It compares it with pre defined criteria such as overcurrent, undervoltage, frequency deviation, external digital inputs from protection relays. When the trigger condition is satisfied, the disturbance recorder freezes the pre fault buffer and continues recording the fault and post fault data for a configured duration. This ensures fault inception, transient behaviour and post fault data or system recovery all captured into a single record.

Memory: The captured data is stored in a non volatile memory like a flash storage. The memory architecture allows circular buffering, with continuous recording without data loss. Modern disturbance recorders can store multiple fault records, event logs and oscillographic files along with metadata such as trigger time, fault type, channel configuration for traceability and analysis.

Communication: The communication module provides access to recorded data for engineers and control centers. Common interfaces are ethernet, RS-485, optical port and IEC-61850 based communications. Data can also be retrieved locally via laptop.

This article is a part of the Metering page, where other articles related to the topic are discussed in details.