Tan delta test, also known as dielectric dissipation factor test is a critical diagnostic test, which is used to assess the insulation health of high voltage electrical equipment such as transformer, bushings, cables, rotating machines and instrument transformers. The tan delta test measures the dielectric losses that occurs when AC voltage is applied to the insulation of high voltage equipment, expressed as the tangent of the loss angle tan δ, the ratio between the resistive current and the capacitive current in the insulation.

In an ideal insulation system, the current leads the voltage by 90 degrees. However, because of introduction of resistive components due to aging, moisture ingress, contamination, thermal stress and partial discharge, the dielectric loss increases, which gets reflected in the tan delta test measurements. The tan delta test value is therefore a sensitive indicator of insulation deterioration long before catastrophic failure occurs. As the tan delta test evaluates the insulation as a whole rather than identifying localized defects, it is widely used for condition assessment and acceptance testing.

Table of Contents

Principle of tan delta test

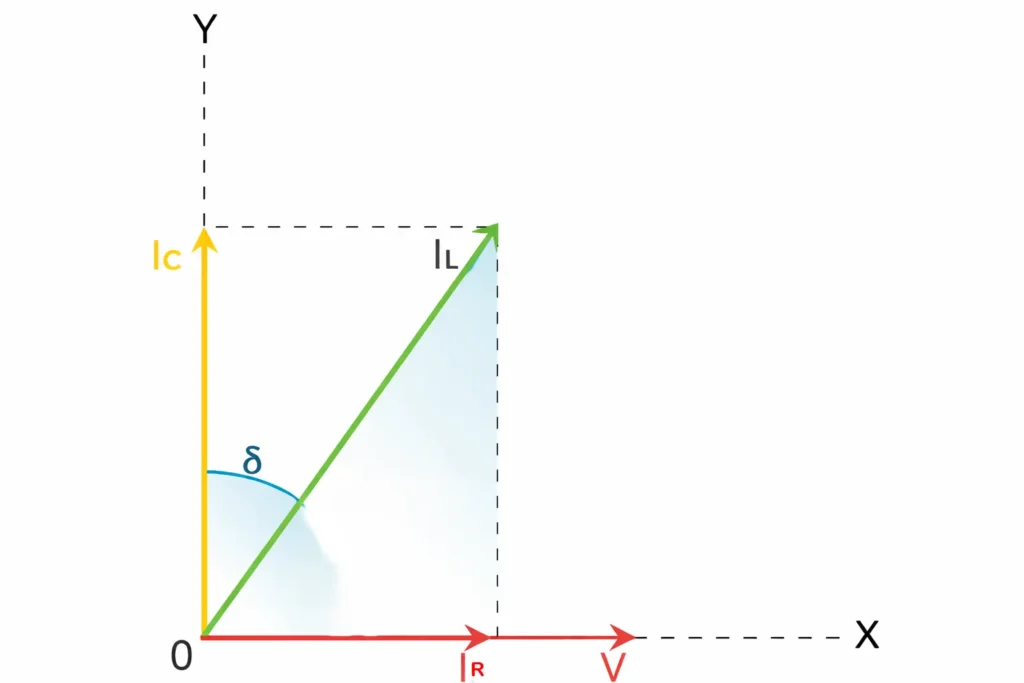

A pure insulator connected between line and earth behaves as a capacitor. In the ideal insulator, the insulating material or dielectric is 100 % pure and the current passing through the insulator will only have capacitive component and no resistive component of the current will flow from the line to earth through the insulator. In pure capacitor, the capacitive current will lead the voltage by 90 degrees.

However, in practice, the insulator cannot be made perfectly pure and because of impurities like dirt, moisture etc will form a conductive current path and will result in leakage current flowing from the line to earth via the insulator. And as a result, the total current through the insulator will contain two components viz

- A capacitive component leading the voltage by 90 degrees and

- A resistive component of current which is in phase with the voltage and is responsible for dielectric heating and energy loss.

The presence of this resistive component causes the current to deviate from the ideal 90-degree phase angle by a small angle delta. The tan δ or tan delta test value is the ratio of the resistive current component to the capacitive current component and shows a direct measure of dielectric loss and insulation deterioration. A higher tan δ means higher resistive component of the current, indicating poor insulation condition.

Tan delta test kit

A tan delta test kit is a specialized high voltage diagnostic instrument containing a variable high voltage AC source with a precision reference capacitor and a measurement unit. The power source is capable to generate very low frequency stable high AC voltage to stress the insulation under test. The measuring unit based on Schering bridge or its digital equivalent separates the capacitive and resistive components of the insulation current and calculates tan δ and capacitance.

The current and the voltage sensors measures the applied voltage and resulting current with accurate phase angle detection, which is essential for reliable calculation. The reference capacitor which is a low loss standard capacitor, used as a reference for comparison, ensuring measurement accuracy and repeatability. The guard circuit provides controlled path to divert surface leakage current, enabling measurement of the insulation only under test.

The control and processing unit processes the raw signal and applies correction, performs the calculation, and displays tan delta, capacitance, and test voltage. While the safety and protection circuit provides interlock, overcurrent protection, and automatic discharge to ensure operator and equipment safety during and after the test is conducted.

Test connection

The tan delta test connection depends on the type of equipment under test with the underlying principle remains the same which is application of the AC voltage to the insulation under test and measure the resulting current and phase angle with respect to the earth.

Basic connection

The high voltage lead of the tan delta test equipment is connected to the terminal of the insulation under test.

The ground lead is connected to the equipment tank, sheath, or grounded structure like bushing flange.

The insulation between the HV terminal and the earth forms the test object.

Measuring lead connection

The measuring or the low voltage lead is connected to the test object return path as defined by the test mode. Modern tan delta test sets internally separate the voltage and the current signals via the bridge and calculates the tan delta electronically.

Guard lead connection

The guard lead is used to bypass the surface leakage currents caused by contamination or moisture. Guarding ensures that the bulk insulation is measured, improving the tan delta test accuracy.

| Equipment | HV Lead | Measuring Lead | Ground Lead | Guard Lead |

| CT | Primary | Internal | Tank | Secondary |

| PT | HV terminal | Internal | Tank | LV winding |

| Bushing (C1) | Top terminal | Test tap | Flange | — |

| Bushing (C2) | Test tap | Internal | Flange | Top terminal |

| Transformer | Tested winding | Internal | Tank | Other windings |

| Cable | Conductor | Internal | Sheath | Other cores |

Modes in testing

Grounded Specimen Test

Grounded specimen Test in the tan delta test is basically used when one side of the insulation under the test is permanently connected to the earth. In this mode the test object is grounded, the tan delta test set applies high voltage to the test object and the leakage current returns to the ground through the insulation. GST mode measures all insulation connected to the ground and hence the result can include unwanted parallel paths.

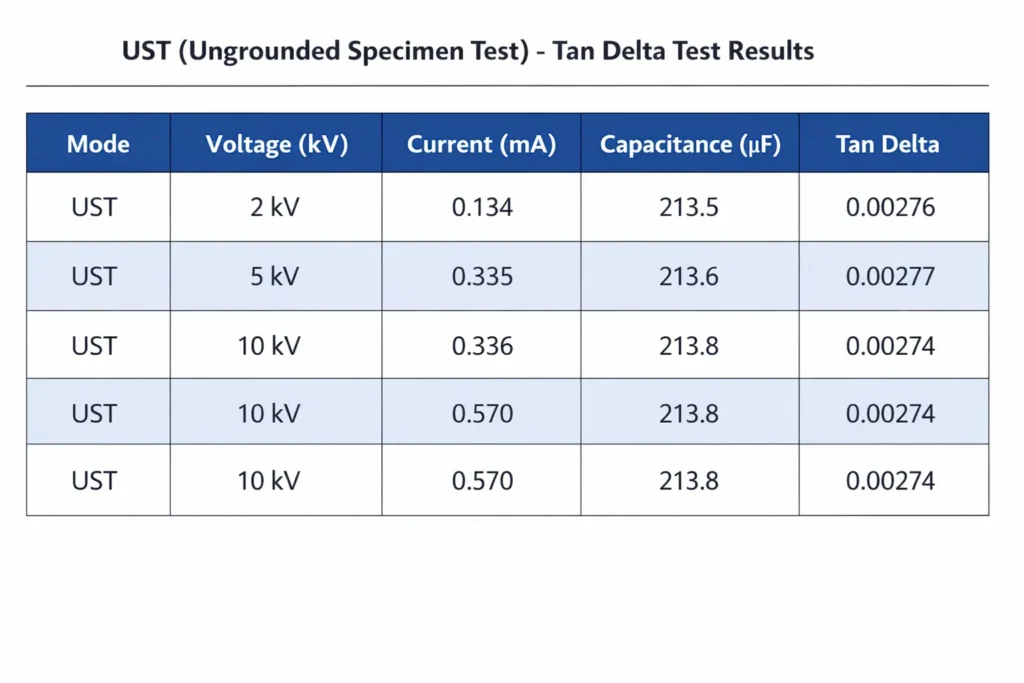

Ungrounded Specimen Test

In this mode, the insulation under test is not grounded and electrically isolated from the earth. Both terminal of the insulation is floating with respect to the ground. The tan delta test set applies voltage across the insulation and the return path is internal through the measuring bridge. In this mode only the selected insulation is measured.

Grounded Specimen Test with Guard

This mode of tan delta test is a modified GST mode in which the specimen is grounded but the unwanted parallel insulation paths must be excluded. In this mode the guard terminal is connected to divert unwanted leakage currents and only insulation of interest contributes to the tan delta measured value.

Tan delta Test steps

Step 1: Ensure the equipment under test is de-energized and isolated.

Step 2: Clean bushing and terminals to remove contaminations.

Step 3: Verify the name plate voltage, insulation class of the equipment.

Step 4: Connect the HV lead to the energizing terminal, measuring or LV lead to the insulation return point, ground lead to the earth terminal and Guard lead to bypass unwanted parallel paths. Recheck polarity and tightness of all connections.

Step 5: Select the test set configuration modes and set the test voltage as per OEM recommendations typically between 2 to 10 KV.

Step 6: increase voltage gradually in steps of 1KV increment and allow the readings to stabilize.

Step 7: Record the tan delta, capacitance and leakage current. Repeat measurement to confirm consistency.

Step 8: Reduce the voltage to zero and discharge the test object and re-earth normal grounding.

Acceptance criteria

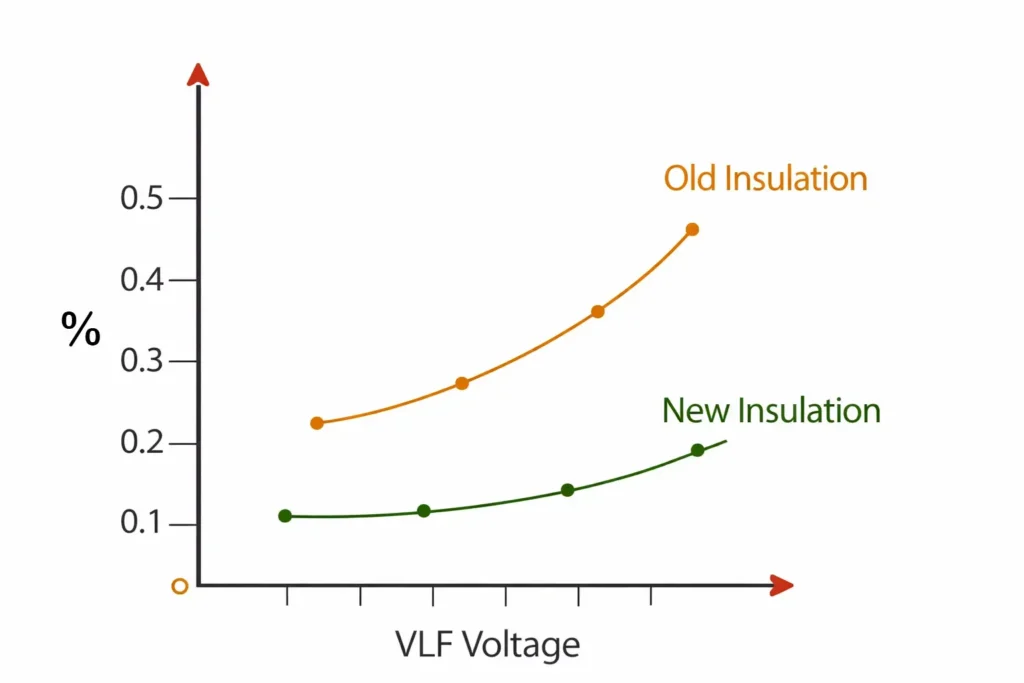

There are two possible ways to assess the condition of the insulation under tan delta test. Firstly, comparing the tan delta test results to previous tests to determine the condition the insulation. And secondly if the tan delta test values for the insulation closely agrees to each other for all range of test voltage then the insulation is perfect. But if the value of tan delta increases more than 0.2% for higher stepped test voltage, then it’s a confirmation that the insulation has degraded.

Absolute tan delta values: As per IEC 60076 and IEC 60247, for new and healthy insulations typical tan delta values must be less than 0.5%. For aged insulations the absolute tan delta value must be less than or equal to 1%, which essentially means moisture ingress and contamination but is still serviceable. A value beyond 2% warrants for detailed investigation.

Phase to phase comparison: Tan delta test values must be uniform between phases. A deviation of values beyond 30% between phases is considered abnormal and indicates localized insulation deterioration.

Capacitance stability: The capacitance must not vary more than ±5% compared to historical and factory values as per IEC 60137, IEEE-81. Significant change in capacitance indicates physical insulation damage as the capacitance is considered as a geometric dependent quantity

Reference

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.