Transformer turns ratio test is a diagnostic and acceptance test which is performed to verify the correctness of transformer’s winding ratio with the designed value and the vector group. Transformer turns ratio test verifies that the primary to secondary turns ratio is correct and ensures that the transformer delivers the specified voltage transformation under operating conditions. Any deviation in the turn’s ratio indicates potential issues, like shorted turns, incorrect tap charger position, winding displacement, or internal manufacturing defects.

This test is usually carried out during the factory acceptance testing (FAT), site acceptance testing (SAT), commissioning and during routine maintenance. Since, the transformer operates as a static device, with no moving parts, small ratio error can lead to circulating currents, unequal load sharing, overheating and false operation of protective relay, during parallel operation. Thus, the transformer turns ratio test is a non-destructive way of validating a transformer’s integrity before energization after major electrical or mechanical maintenance.

Table of Contents

Working Principle

Voltage ratio vs turns ratio

The principle of the transformer turns ratio test is based on the direct relationship between voltage ratio and turns ratio. In the ideal transformer the ratio of the primary voltage to the secondary voltage is equal to the ratio of number of turns in the primary winding to the number of turns in the secondary winding. i.e, V1/V2 = N1/N2. Therefore, by applying a known alternating voltage to one winding, the actual turns ratio can be determined accurately. Any deviation from the nameplate ratio indicates possibility of internal defects or winding faults, which is affecting the electromagnetic behaviour of the transformer.

Application of Faraday’s Law

The transformer turns ratio test is fundamentally governed by Faraday’s law of electromagnetic induction. When an alternating voltage is applied to the transformer winding, it produces a time varying magnetic flux in the core of the transformer. This changing flux links the other winding and induces electromotive force, which is proportional to the rate of change of flux and the number of turns present in that winding. Since, both the windings share same core flux, the induced voltages are directly proportional to their respective turns. This physical law forms the theoretical basis for ratio measurement and ensures that the induced voltage accurately follows the turns relationship.

Measurement with low voltage excitation

Transformer turns ratio measurement is performed using low voltage excitation, which ensures safety and accuracy. A controlled low voltage AC is applied to one winding and induced voltage is measured on the corresponding winding. Low voltage excitation prevents core saturation, avoids inducing stress in the insulation and thermal effects in the winding resistance. Modern transformer turns ratio testers uses stable internal voltage source and digital sensing circuits to provide precise ratio readings.

Test Equipment

Automatic transformer turns ratio meter

The automatic transformer turns ratio meter is the primary instrument used to measure the ratio between the test transformer windings. It applies a low voltage AC excitation to the windings and automatically measures the induced voltage on the secondary winding. This instrument can automatically calculate the turns ratio and compare it to the nameplate value, thus eliminating the need for manual calculation and reduces human error.

Modern transformer turns ratio meter includes the phase angle and excitation current measurement capabilities which enhances the diagnostic values. The phase angle measurement helps verify the transformer vector group and polarity by analysing the angular displacement between the primary and secondary voltages.

Excitation current measurement provides greater insight into core condition of the transformer as it is directly influenced by the magnetic properties and physical integrity of the transformer core.

Transformer turns ratio test connections

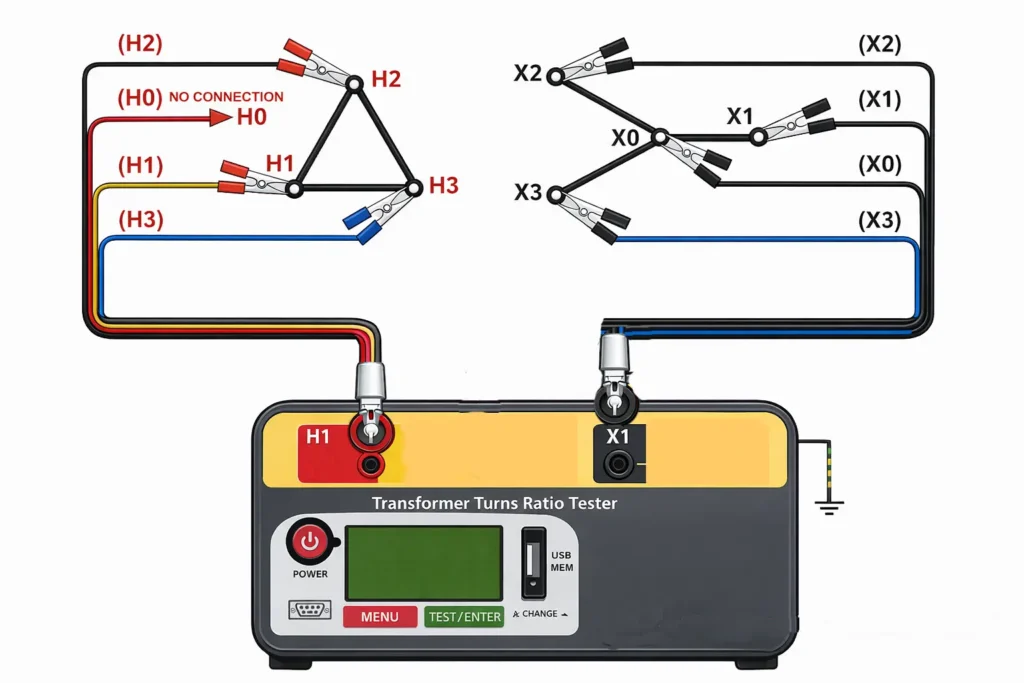

In a transformer turns ratio test, the instrument applies few tens of volt to the primary winding of the transformer and measures the induced voltage on the corresponding winding of the transformer. For three phase transformers, the modern transformer turns ratio test sets are designed to connect and excite all three phases simultaneously ensuring balanced magnetization of the core.

Primary side connection

The connection leads are connected to all three phases of the test transformer including neutral if required by the vector group and the other end is connected to H of the instrument.

Secondary side connection

Voltage sensing leads are connected to the corresponding secondary side of the transformer and to the X of the instrument.

Vector group consideration

Before testing, correct vector group has to be selected in the testing instrument because the transformer’s internal phase displacement and winding connection directly influences how voltage appears at the secondary terminal during the test.

The delta side voltages for phase A, B, C are VA-B, VB-C and VC-A, while the star side voltages for a,b,c phases are Va-n, Vb-n, Vc-n. Also, the vector groups introduce phase shifts in the transformer. Correct selection of the vector group allows the instrument to do internal phase correction without which the instrument measures phase shifted values resulting in incorrect ratio and polarity readings.

The measuring instrument must know which HV and LV terminals are magnetically coupled, wrong vector group selection causes the instrument to compare non corresponding windings producing abnormal ratios.

Test procedure

Step1: Isolate the transformer which is to be tested from incoming and out going sources. Ensure all breakers and isolators are in open condition. Discharge the windings to eliminate any trapped charges.

Step2: Confirm the tap changer position before testing and record the tap number. Ensure that the tap changer is properly locked into position.

Step3: Disconnect all external cables, busbar, neutral grounding resistors or parallel transformer connection that can influence the measurement.

Step4: Verify the transformers name plate such as rated voltages, turns ratio, vector group and tap range. Use these values as a reference for evaluating the test results.

Step5: Make the connections between the transformer terminal and measuring instrument’s terminal correctly.

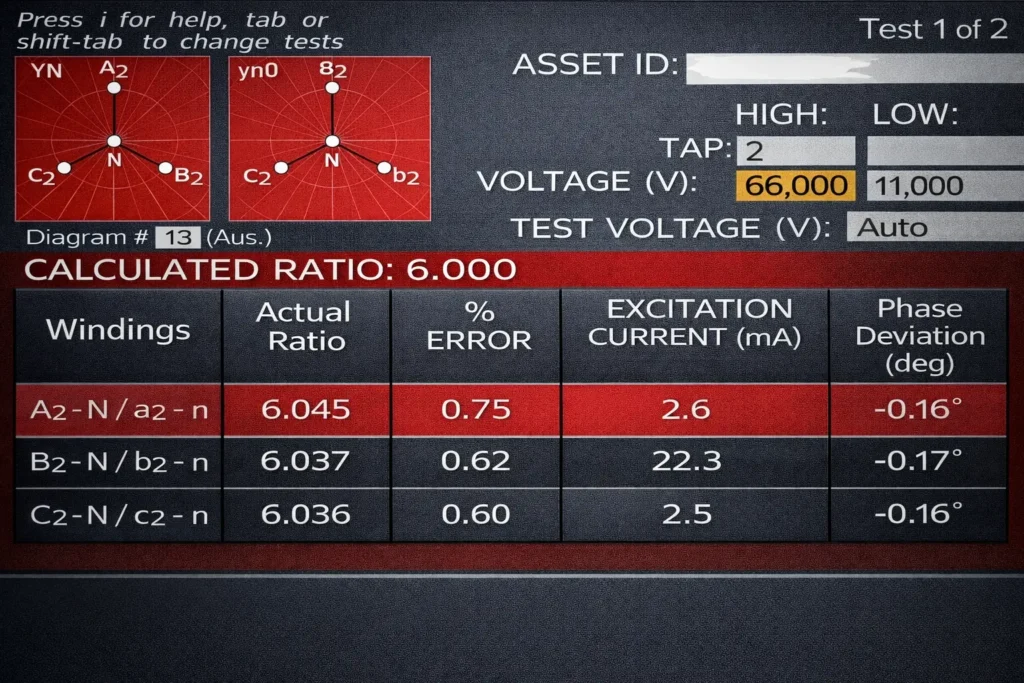

Step6: Start the test by pressing test button on the instrument, which will inject test voltage and record the test results, such as measured turns ratio, percentage deviation from the original, excitation current and phase angle. Although excitation is applied simultaneously, the test instrument processes each phase separately and independently enabling detection of phase wise ratio errors and abnormal excitation current.

Formula for ratio deviation

Step7: Carryout the test for every tap position. Ensure that the tap changer is correctly positioned before each measurement.

Acceptance criteria

Permissible ratio deviation limit of transformer turns ratio test

The measured turns ratio should be typically within ±0.5% of the nameplate ratio for most power transformer and distribution transformer. However, some manufacturers and utilities practice tighter limits such as ±0.2 % for the new and critical units.

Phase to phase comparison

For three phase transformers, the measured ratio values of all phases must closely agree to each other. Any deviation exceeding 0.3-0.5% is considered abnormal and indicates winding defect or tap changer issue.

Interpretation of results

Detection of shorted or open turns

If the measured turns ratio in transformer turns ratio test is significantly higher or lower than the nameplate ratio, it indicates a shorted or open turns in the winding. V1/V2 = N1/N2, the ratio N1/N2 can only increase if N1 increases, the turns on the primary can never increase by itself. However, N2, the turns on the secondary can decrease if it gets shorted. Similarly, the ratio N1/N2 can only decrease if N2 increases which is not possible and N1 decreases, which can be result of shorted primary winding.

Tap changer contact issue

Inconsistent ratio reading during the transformer turns ratio test between adjacent tap positions suggests poor tap changer contact, misalignment or contact wear. Stable ratio at all other taps helps localize the problem in the tap changer mechanism.

Winding displacement indication

During the transformer turns ratio test, sudden changes in the ratio or phase angle compared to historical records indicates winding movement or mechanical displacement caused due to short-circuit forces, transportation or seismic stress.

Abnormal excitation current

Elevated or uneven excitation current readings indicates core related issues in the transformer, partial shorted turns, residual magnetism, or incorrect test connection. Trending excitation current over the time indicates developing internal abnormality in the transformer.

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.