The Grounding electrode conductor is the most essential part, that forms the backbone of any grounding system because it forms the main low impedance path through which the fault current and lightning energy gets safely dissipated to the earth. Without the grounding electrode conductor even the best of electrodes will fail. Many electrician treat grounding electrode conductor as just a wire connecting the panel to ground electrode, while engineers understands that it is designed and sized based on standards for safety.

Poor installation, loose joints, sharp bends, under sizing and corrosion will result in maloperations in substations, lightning failures in towers and equipment damage. This article will cover the function of grounding electrode conductor, its applicable standards, sizing rules, routing practice in the industry with essential dos and don’ts for reliable grounding performance.

Table of Contents

Definition

Grounding Electrode Conductor, GEC is the conductor that connects the main grounding bar or the neutral bar to the grounding electrode buried in the soil. The main purpose of the Grounding electrode conductor is to provide a low impedance path to the unwanted currents to flow into the earth safely. This essentially includes the fault currents during short circuit, lightning surges, switching surges, leakage currents from insulators and static charges building up in the equipment. It prevents dangerous voltage built up in the equipment.

Functions of Grounding Electrode Conductor

Low impedance path: The grounding electrode conductor offers a shortest low impedance direct path to all unwanted electrical energy to flow in to the earth safely. The minimization of the impedance, it diverts the fault current, quickly and efficiently there by preventing any dangerous potential build up on the equipment, structure and metallic parts.

Carry High magnitude fault current: During short circuit or lightning strike, the grounding electrode conductor must withstand extremely high current without any thermal stress and structural damage. A well engineered conductor, conducts this high current to the earth electrodes while keeping the connected equipment and structures at safe potential nullifying the risks of flash over, equipment stress and thermal failure.

Establishment of stable ground potential: Grounding creates the fixed zero volt reference for the entire electrical installation. With the neutral tied along with the equipment frame, metallic conduits and support structures to a common grounding point, the grounding electrode conductor ensures all component of the system operates around the same potential level. This reduces the voltage fluctuation and prevents floating potentials in the substation or installation with enhanced measurement accuracy.

Step and touch voltage control: Well designed grounding grid formed from the grounding electrode conductors greatly limits the ground potential rise by spreading the fault current uniformly and evenly in the soil. This reduces the step and touch potentials which are crucial for personnel safety in outdoor switchyards during faults.

Bonds all electrodes into a single earthing system: Effective grounding system connects the rods, pipes, plate, strips and meshes into a integrated grounding network. This bonding provides equal potential across the substation, preventing isolated high resistance electrode, creating dangerous voltage gradients. This bonding is achieved by the grounding electrode conductor which improves the current dissipation factor and lowers overall ground resistance.

It may be noted that not all electrodes are connected always like lightning arresters usually have a separate grounding electrodes, instrumentation grounding are done separately to reduce the noise.

Materials for GEC

Bare copper: Bare copper is an excellent conductive material used as grounding electrode conductor. Because of its high conductivity (58MS/m) and good corrosion resistance(0.005mm/year), it offers long term stability in grounding. It handles high fault current with minimal thermal stress as its melting point is high (1085°C) and maintains the low impedance over decades. It is ideal for substations, transformer neutral and other critical grounding applications.

Tinned copper: It is a copper conductor with a tin coating of 2 to 15 µm, which prevents the metal from oxidation in saline or acidic soil (pH < 5.5). This grounding conductor material performs excellent in coastal zones where chloride concentration exceeds 500 ppm. It retains copper’s conductivity of around 58 MS/m, ensuring long service life in marine substations and corrosive environments.

Copper Bonded Steel: This material is essentially a high strength steel core with a 250 to 300 µm copper plating. It offers excellent conductivity in lowered cost compared to solid copper conductors. With tensile strength of about 600 N/mm2, it resists bending during installation with good performance in tower grounding.

GI strip or GI wire: Galvanised iron conductors uses a steel core coated with 70 to 100 µm Zinc, which provides the corrosion resistance in neutral to mild alkaline soil (pH 6.5-8.5). Although the conductivity of GI is lower, it is cost effective and is accepted in the industry for bonding, grounding grid and grounding grid conductors capable of carrying 10-15 KA fault current.

| Material | Typical Size (mm) | Area (mm²) | k-value | Fault Capacity (1 s) (kA) | Remarks |

| Bare Copper Strip | 25 × 4 | 100 | 205 | 20.5 kA | High conductivity; critical GEC |

| 32 × 6 | 192 | 205 | 39.6 kA | Widely used in EHV GEC | |

| 50 × 6 | 300 | 205 | 61.0 kA | High grid currents; substations | |

| Tinned Copper Strip | 32 × 6 | 192 | 205 | 39.3 kA | Corrosion-resistant; marine/coastal |

| 50 × 6 | 300 | 205 | 61.5 kA | Critical coastal/industrial applications | |

| Copper-Bonded Steel | 25 × 3 | 75 | 80 | 6 kA | Cost-effective; medium soil grids |

| 32 × 6 | 192 | 80 | 15.3 kA | Suitable for tower earthing | |

| GI / Steel Strip | 25 × 3 | 75 | 80 | 6 kA | Small industrial grids |

| 32 × 6 | 192 | 80 | 15.3 kA | Standard substation grid strips | |

| 50 × 6 | 300 | 80 | 24 kA | High-capacity grids; 132 kV | |

| 75 × 10 | 750 | 80 | 60 kA | Large substation grounding grids; high mechanical strength | |

| GI Round Conductor | 10 mm dia | 78 | 80 | 6.2 kA | Tower footings / fencing |

| 12 mm dia | 113 | 80 | 9.05 kA | Horizontal grid runs | |

| 16 mm dia | 201 | 80 | 16.08 kA | Larger tower/mast earth conductors |

Sizing of grounding electrode conductor

The sizing of grounding electrode conductor is basically done based on fault current and thermal withstanding capacity for worst case fault current using IEEE-80 formula

S = I √t / k,

Where, S = conductor cross-sectional area,

- I= Fault current in A,

- t= Fault clearing time

- k= material constant in A.s1/2/mm2

Typical value of k for copper = 205 A.s1/2/mm2, Galvanised iron = 80 A.s1/2/mm2

Considering the short time current rating to be 31.5 KA and time of fault clearing as 1 seconds,

For copper, S = 31.5 x 1000 √1 /205 = 153.65 mm2

Including the derating factors

| Factor | Typical Derating |

| Corrosion allowance | 1.1–1.2 |

| Mechanical strength | 1.1–1.5 |

| Lightning / surge currents | 1.2–1.5 |

| Continuous leakage current | 1.1–1.2 |

Combining derating factors depending upon the site conditions and conductor materials,

For copper = 153.65 x 1.1 x 1.1 x 1.2 x 1.1 =245.40 mm2

For GI = 31.5 x 1000 √1 /80 x 1.1 x 1.1 x 1.2 x 1.1 = 628.9 mm2

From the standard value list we select the minimum size based on 30% of the short time current rating as only 30% will flow to the ground and rest will return to the source via the metallic path. 30% of 31.5 KA is around 9 KA.

Why 30% is considered?

This is because of the fault current division. Ground has a finite resistance and metal has resistance even lower than the ground.

The current division follows ohms law

Iground = Itotal x Rmetal / (Rmetal +R Ground)

Considering the resistance of earth to be 0.7 Ω (less than 1 Ω for substation) and that of metal to be 0.2 Ω,

Iground = 31.5 x 0.2 / (0.2+0.7) = 6.99 KA

Therefore, selected copper conductor size is 25 mm x 4 mm and for GI the standard size is 32 mm x 6 mm or, 50 mm x 6 mm based on ground fault current for 1s (30% of the short time current rating) and market availability.

Routing rules

Short straight path: Run the grounding conductor directly and as straight as possible from the main earth bar to the grounding electrode. Avoid the bends as corners increases the inductance and reduces the effectiveness during lightning and high fault currents. Even little impedance in the path due to bends can cause voltage spikes because of the high fault currents so it is necessary to avoid 90 degree turns.

Mechanical protection: The GEC should be protected wherever it rises above ground via GI pipes and conduits. Routing along side the high current cable can cause magnetic induction and heating and hence it should be avoided. Mechanical protection is needed because if the GEC is nicked or damaged, high current during fault can melt the conductor and cause a disconnection which is dangerous.

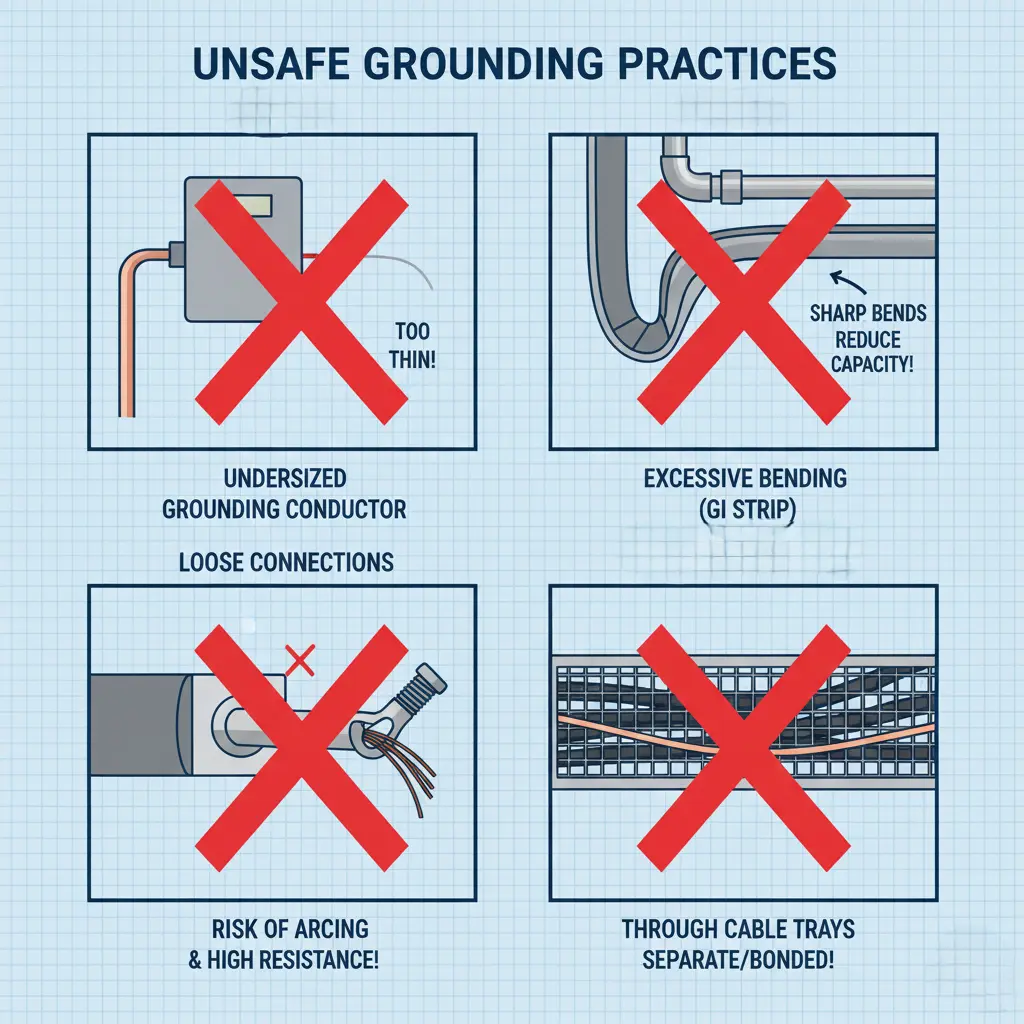

Common mistakes

Using undersized conductors: Undersized conductors cannot carry the high fault current and melts away which leads to excessive voltage rise and even cause fire hazard.

Loose terminal connection: Loose or poorly connected bolts or lugs causes high contact resistance, during faults, local heating can cause damage to the connector and conductor as well. It can even cause the protection device to trip slower because of reduced fault current because of high contact resistance.

Too many bends: Every bend in the grounding electrode conductor raises the inductance which opposes rapid fault currents. Excessive bends also increases the effective length of the conductor and as a result, the resistance also increases.

Routing of grounding conductor in cable trays: Cable trays are made for power cable and control cables not for high current carrying GECs, running the grounding electrode conductor through it will increase the inductance which will reduce the current dissipation.

Using cables instead of strips: Cables are flexible and convenient but in high fault areas, they overheat quickly and melts. While flat strips and bars offers higher surface area and lower inductance with better current carrying capacity.

Tip: A substation grounding system is only as good as the weakest conductor or connection.

This article is a part of the Safety and Earthing page, where other articles related to topic are discussed in details.