A fiber optic cable (FO cable) is a medium of high speed data transmission is made as information is carried by the pulses of light through thin strands of glass or plastic fibers. Unlike the copper cables which transmits electrical signals, the fiber optic cable (FO cable) uses light that allows higher bandwidth and faster data transmission rates over longer distances with very minimal loss in signal. The fiber optic cable (FO cable) are immune to electromagnetic induction making them ideal for places with electrical noise such as substation, industrial plants, etc. Since, FO cable provides long range, high capacity and reliable data transmission, therefore it becomes essential for advanced control system, internet and modern telecommunication as well.

Table of Contents

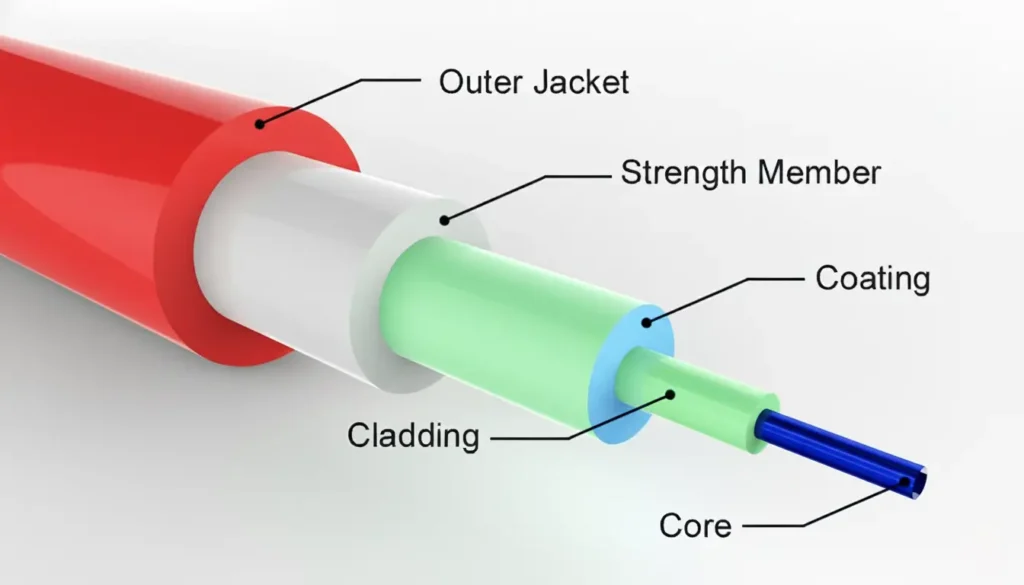

Construction

Core: The core is the central region that carries the light in the fiber optic cable (FO cable). It is made of glass which is ultra pure (99.9999%) doped silica (SiO2) or with high grade plastic with higher refractive index between 1.450 to 1.467 for single mode fiber and 1.48 to 1.50 for multimode fiber, which guides the data as light pulses with minimal loss. Typical diameter of the core is 9 μm for single mode fiber and 62.5 or 50 μm for multimode fibers, which is selected based on distance, bandwidth and required application.

Cladding: It is a special engineered glass or plastic layer that surrounds the core which has a refractive index slightly lower than the core 1.444 to 1.455 for single mode fiber and 1.46 for multimode fiber. The lower refractive index of the cladding helps the light to remain trapped within the core through total internal reflection. The cladding maintains the signal strength while allowing the FO cable to bend moderately, with efficient and ling distance light transmission. The diameter of the cladding is always 125 μm.

Coating: It is the primary buffer between the glass fiber (core + cladding) and the outer jacket. Coating is basically a soft protective polymer layer applied over the cladding. It protects the delicate glass fiber from micro bending and stress, moisture, abrasion, mechanical damage and UV effect during installation and operation. The material used for the coating is usually UV cured acrylate. This layer in the FO cable prevents crack, ensuring optimum optical performance in both the indoor and outdoor environments.

Strength Members: The strength members which is usually aramid yarn (Kevlar) for indoor installation and fiberglass rods for outdoor installation, are used to provide mechanical support to the fiber optic cable. Also known as the mechanical backbone of the fiber optic cable, the strength member must limit the fiber strain within 0.6% as per IEC 60794. It absorbs the tensile load during installation of the cable, while maintaining the cable roundness and prevent micro bending. It also maintains the cable stability with temperature changes and adds to the crush resistance of the FO cable, making it durable for aerial, underground and high stress industrial environments.

Outer Jacket: The outer jacket or the external protective layer of the Fiber optic cable is made from PVC or LSZH (Low Smoke Zero Halogen) or PE. It provides protection to the internal components of the FO cable from moisture, abrasion, chemical, oil and UV exposure. The selection of the jacket material depends on the environmental conditions for longer service life and reliable performance. The thickness of the outer jacket varies from 1 to 3.5 mm with a tensile strength of 9 to 25 MPa with 2.5% carbon black addition for making it UV resistant.

Working principle

Fiber optic cables work on the principle of total internal reflection, which makes the light to travel long distance through the cable with very less loss. A transmitter led or laser sends the light pulses into the core of the cable. Because of the cladding with a lower refractive index than the core, the light is continuously reflected back into the core rather than escaping from it. This reflection guide the light along the fiber, carrying the digital information inform of rapid light pulses. At the receiving end, a photo detector converts the light back to electrical signals. This optical transmission enables extremely high bandwidth with immunity of electromagnetic interference.

Types of FO cable

Based on Mode

Single mode fiber: These FO cables carries the light through a very small core, allowing the signal to travel long distance with extremely attenuation. With high bandwidth support, it becomes ideal for transmission networks and telecom operators, It is also preferred for Wide Area Networks (WAN), smart grid communication with high speed data links spanning hundreds of kilometers.

Multimode fiber: These fiber optic cable uses larger core with multiple path for the light to travel. This mode is suitable for short distance communication. It is used widely in Local Area Networks (LAN), data centers, industrial automation and control rooms. It supports economical high speed links within 500 meters making it ideal for short reach instrumentation links.

Based on construction

Tight buffered fiber: These FO cables have each fiber coated with thick protective layer making it robust for indoor routing. The cable is easy to strip with simple termination ideal for control room, riser, short patch runs. With moderate moisture resistivity, it is best suited for building installations.

Loose tube fiber: These fiber optic cables contains fibers inside gel filled or dry water blocked tubes which offers excellent moisture and temperature resistance. Designed for outdoor use, these cables are ideal for underground ducts, poles and long distance telecom links. The construction of these cables minimizes the fiber strain while providing reliable performance in harsh environments.

Armoured fiber cable: These FO cable essentially includes steel tape or steel wire layers to provide strong protection against rodents and crushing loads. It is used in substations, industrial areas and underground trenches. This design ensures high durability while protecting the fibers in high physical damage prone areas.

Special types

Aerial ADSS (All Dielectric Self Supporting): These fiber optic cable are designed for overhead installation on power line poles with no metallic components. These can easily withstand electrical field, wind and mechanical tension. Besides being light weight and strong, ADSS is widely used in transmission and distribution networks for OPGW alternative. It supports faster installation with no need for messenger wire or grounding.

Ribbon fiber: These FO cable usually groups multiple fiber in a flat ribbon like structure which enables mass splicing. This speeds up the installation and restoration work in backbone networks. It is suitable for high fiber count telecom networks, data centers, etc. It also optimizes the space requirement and supports dense optical connectivity.

Drop fiber (FTTH): These fiber optic cables are used for connecting the distribution network to individual home or offices in the FTTH (Fiber To The Home) system. These cables are light weight, easy to handle and designed for direct access routes with tight bending capacity and smaller size. It ensures high connectivity and reliable internet speed for smart home services.

Submarine optical cable: These are specially engineered fiber optic cables for deep sea communication, with waterproof layers, steel wire armour and pressure resistant construction. This cables are responsible for carrying international internet traffic across ocean with extremely low loss because ocean offers a straight path between continents with lower risks of physical damage compared to land route and also avoids geographical barriers. These cables are designed to withstand current and marine hazards.

Advantage and Limitations of Fiber optic cable

| ADVANTAGES | LIMITATIONS |

| Fiber optic cables offer a very high bandwidth up to 1.2 Tbps. | The initial cost of installation is very high |

| It has a very low attenuation. | It requires specialized splicing and testing equipment. |

| Since it is light based, it is immune to electromagnetic interference. | The cables are fragile. |

| These cables are light weight and offers secure data transmission. | Sensitive to tight bends and mechanical stress. |

Fiber optic vs copper cable

| Parameter | Fiber Optic Cable | Copper Cable (Twisted Pair / Coax) |

| Medium | Glass or plastic fiber | Copper conductor |

| Signal Type | Light signal | Electrical signal |

| Bandwidth | Very high (Gbps to Tbps) | Limited (up to 10 Gbps for Cat6A/7) |

| Distance | Up to 40 to 80 km without repeaters | Up to 100 m (Ethernet) or few km for coax |

| Speed | 10 Gbps to 400 Gbps+ | 1 Gbps (Cat5e/6) and maximum of 10 Gbps (Cat6A/7) |

| Interference | Immune to EMI/RFI, lightning | Prone to electromagnetic interference |

| Security | Very high (no radiated signal) | Lower, as it can be tapped easily |

| Weight | Light | Heavy |

| Installation Cost | Medium to high | Low |

| Maintenance | Specialized equipment and personnel required | Easy & cheap |

| Environmental Durability | Resistant to corrosion, moisture | Prone to corrosion and thus higher losses |

| Applications | FTTH, backbone, data centers, submarine | Home networking, CCTV, industrial control |

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.