ABC cable or (Aerial Bundled Cable) is basically an overhead distribution cable system, which consists of insulated phase conductors, bundled together with a bare or in some cases insulated neutral messenger. The use of ABC cables has an improved safety, reduced electrical fault from foreign object contact as the ABC cables has insulated phases, minimized the power outages and also lowers the maintenance costs. ABC cables decrease the issue of power theft while improving the reliability of power distribution in the congested or urban areas.

The technology of ABC cables emerged between 1960s to 70s in Europe for preventing the phase-to-phase fault in the low voltage distribution system ensuring safety. However, power utilities adopted it for low voltage and medium voltage power networks because of superior mechanical strength and insulation with excellent performance in difficult terrain and population dense zone.

Table of Contents

Technical specification

ABC cables are designed according to IEC standards for ensuring safe and reliable power distribution. The low voltage cables (0.6 to 1 KV) follows the IEC 60502-1, while the medium voltage level (11 and 33 KV) follows IEC 60502-2. The conductor of the cable is aluminium as per IEC 60228 typically sized around 16 to 150 mm2 while the messenger wire is around 25 to 70 mm2 AAAC or ACSR.

The XLPE insulation supports a continuous operating temperature of around 90 °C and 250 °C during short circuit for 5-seconds. The short circuit current rating of the cable is around 2.5 to 9 KA depending upon the size of the conductor derived by IEC 60949 thermal short circuit calculation.

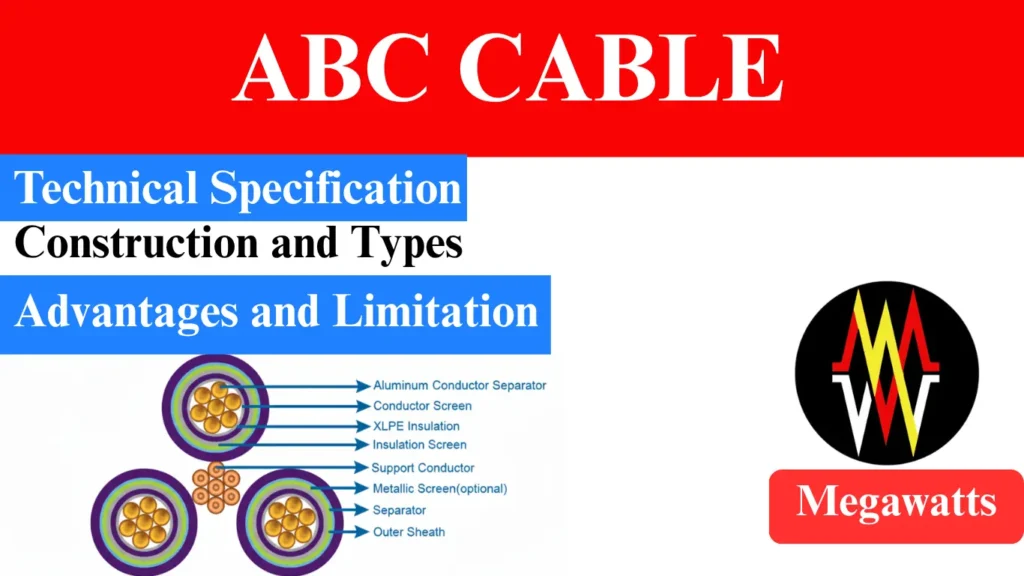

Construction

Conductor: ABC cable basically uses aluminium conductor for it being lightweight and economical for overhead power distribution. The cores of the cable are class-2 stranded as per IEC 60228 and IEC 60502 because the cable requires high mechanical strength, long span tension support and has fixed installation characteristics. Besides being light weight, aluminium has better corrosion resistance property which makes it ideal for long span low voltage and medium voltage aerial application.

Insulation: The phase conductor of ABC cable is insulated with XLPE (cross-linked polyethylene) or PE (Polyethylene) with a insulation thickness ranging from 0.8 to 1.2 mm (for 16-35 mm2) and 1.2 to 1.5 mm (for 50-120 mm2) for withstanding the outdoor exposure. The XLPE insulation offers higher thermal rating and excellent dielectric strength while also provides long term aging resistance. The PE insulation provides flexibility and good weather resistance. Both the insulation material includes UV stabilizer for protection of the cable against sunlight exposure, moisture and other environmental degradation.

Messenger wire: The messenger wire of the ABC cable is a steel or aluminium alloy wire which acts as the load bearing element in the design. It is responsible for supporting the weight of the ABC cable across distribution poles while maintaining proper sag and tension. In some cases the messenger wire also serves as the neutral conductor. It is usually a class 2 stranded AAAC or ACSR conductor with a typical cross section of 25-95 mm2. It’s high tensile strength provides reliable performance in areas with long span and high winds.

Assembly: The cables with the insulated cores are helically twisted around the messenger wire, which bears the mechanical load, forms a stable bundle. Common configuration includes 3-phases and a neutral or 2-phases with a neutral for LT circuits and a 4 core self-supporting without the messenger wire. The tight helical twist improves the mechanical strength of the cable with uniform load distribution, reduced EMI and the consistent spacing between the core improves the capacitance balance of the cable.

Types

Single core service drop: The single core service drop cable supplies the power from distribution pole to individual consumer. It consists of an insulated aluminium phase conductor which is supported by a messenger wire that carries the mechanical load of the cable. The configuration is easy to handle, economic and ideal for short span in residential areas for a single phase service connection.

Three core + Messenger: The three core + messenger ABC cable configuration has three insulated aluminium phase conductor helically twisted around galvanized steel or aluminium alloy messenger, which supports the mechanical tension and the insulated phases deliver the electrical power reliably. This type of arrangement is in wide use in the LV distribution because of improved safety and minimized power theft.

Four core bundle: The four core ABC cable has three insulated phase cores and one insulated neutral conductor twisted together without the separate messenger wire. This design is a self-supporting design of the cable which is suitable for short span, street distribution networks and installations requiring compact and maintenance free low voltage connection.

Duplex, triplex and quadplex configuration: Duplex, triplex and Quadplex configuration uses 2, 3, 4 insulated conductors twisted around a messenger wire in order to match the phase requirement. The duplex configuration serves single phase loads while the triplex supports two phase system and quadplex supports three phase and a neutral while the messenger supports the mechanical load and reduces the sag in varied power distribution circumstances.

LT vs HT ABC cable

| Parameter | LT ABC (Low-Tension Aerial Bundled Cable) | HT ABC (High-Tension Aerial Bundled Cable) |

| Voltage Level | Up to 1 kV | 11 kV to 33 kV |

| Construction | 2–4 XLPE-insulated phase cores + neutral, bundled around messenger | Single-core XLPE-insulated MV conductors with screens; can be twisted around messenger |

| Insulation Type | XLPE/PE (90°C continous operation) | XLPE (MV grade, 90°C continous operation), with semiconducting screens |

| Messenger Wire | AAAC or ACSR (load-bearing) | Usually insulated messenger or independent support |

| Core Arrangement | Helically twisted around messenger | Either twisted single cores or spaced Medium Voltage cores |

| Application | Service drops, LT feeders, street lighting, anti-theft networks | MV distribution in forests, hilly areas, coastal zones |

| Fault Reduction | Prevents phase touching, reduces theft and outages | Minimizes tree contact, lightning flashovers, contamination faults |

| Mechanical Strength | Moderate; messenger supports weight | Higher; MV-grade mechanical and electrical strength |

| Safety Level | High, ideal for public areas | Very high, for critical Medium Voltage lines |

| Cost | Lower | Higher (MV insulation + screens) |

| Maintenance | Simple; easy replacement | Moderate; requires skilled handling |

| Typical Standards | IEC 60502-1 | IEC 60502-2 |

Advantages

Reduced power theft: Because of insulated conductors, illegal tapping becomes difficult, which reduces power theft and improves system efficiency.

Lower Installation cost compared to underground cable: As the ABC cables requires non trench, it can be installed with less labour and few civil works compared to UG cables.

Improved safety: Insulated cores are not prone to faults caused by foreign object touching the cable like trees, which improves the safety and reduces maintenance.

Better reliability: The cable is engineered to withstand all weather condition, moisture and prevents accidental contact compared to bare conductors.

Limitations

Higher losses: compared to UG cable the resistive losses are higher in the ABC cables.

Requires stronger poles and tensioning: Heavier bundled cables requires robust support poles and tensioned messenger wires.

Limited usage: The usage of this cable is limited to 33 KV only as it is not suitable for transmission level voltages and long distance HV lines.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.