DC cables are special type of power cable which are designed for the reliable transmission of direct current with minimal drop in voltage and thermal energy loss. Unlike AC cables, the DC cables do not have the skin effect, capacitive or inductive reactance, thus making the utilization of the full conductor to transmit the electric current, possible. However, control on the insulation of the DC cables must be high as they are subjected to continuous voltage stress.

In AC cable, the insulation faces alternating electric field, but in case of DC cable, the insulation faces constant unidirectional stress which causes the insulation to age faster. DC cables are widely used in substation for closing and tripping circuit of breaker, in battery banks, PV solar arrays, railway signaling, data centers, etc.

Table of Contents

Construction

Conductor: The DC cable conductors are made of copper or aluminium designed as class-2 solid or thick stranded conductors specifically for fixed installation types and class-5 with thin stranding for high flexibility used in battery and UPS system. The conductor sizing in DC cables depends on voltage drop limits, thermal rating and fault withstand capacity as full cross section of the conductor is utilized without skin effect.

Insulation: The insulation in these cables uses Poly vinyl chloride (PVC), Cross-linked polyethylene (XLPE) or Ethylene Propylene Rubber (EPR) insulation designed for continuous unidirectional voltage stress. While the XLPE offers superior temperature rating up to 90 degree Celsius and low dielectric loss, EPR insulation provides superior flexibility. The insulation must withstand long term DC ageing, space charge accumulation, and continuous electric field stress.

Sheath: The sheath is made of PVC, PE or LSZH which protects the DC cable from moisture, chemicals, UV radiation and mechanical abrasion. The PVC insulation provides economical indoor protection while the PE is excellent in outdoor applications and LSZH is used for low smoke, and non-corrosive emission in the substation, control room and data centers.

Armour: These cable includes steel wire armour (SWA) for enhancing the tensile strength in the underground or industrial application. The steel tape is also used as armour in many cable for protection against the radial impact. The armour makes the cable mechanically robust without any affect in the current carrying capacity of the cable.

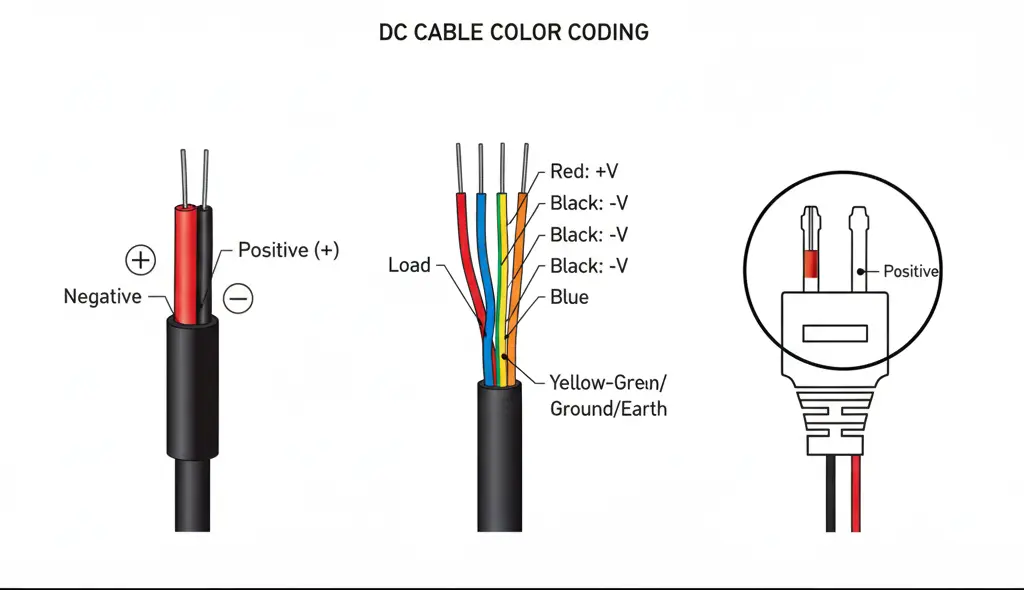

Colour coding: Standard coding rule is used here as RED for the positive and Black for the negative, Yellow or Green is used for the protective earth. The colour coding ensures the clear polarity identification during installation and maintenance nullifying the reverse polarity faults.

Voltage drop calculation of DC cable

Voltage Drop for a DC circuit is Vdrop = I x RLoop,

Where I is the DC current in Ampere and Rloop = R20 x Loop_Km x (1+ α(T-20)),

Where, R20 is the resistance at 20 degree Celsius, Loop_Km = 2 x one way length and α is the temperature coefficient of the conductor which is 0.00393/°C for copper and 0.00403 /°C for aluminium.

Steps:

- Pick conductor area Amm2

- Calculate R20 corresponding to the cross sectional area of the conductor,

- Calculate the loop length in Km which is 2 x one way length(m) / 1000

- Calculate the RLoop 20 = R20 x LLoop

- Use the temperature correction: RLoop = RLoop 20 x (1 + α(T-20))

- Calculate voltage drop: Vdrop = I x RLoop

- Calculate percentage voltage drop = 100 x (Vdrop / VSupply), which is usually 3 to 5% as per utility practice.

Example: Take the area of a copper conductor be 10 mm2 with current supply of 50 A and 30 m one way distance with T= 20 °C

- R20 = 1.7241Ω/km,

- Loop = 60m =0.06 Km, RLoop = 1.7241 X 0.06 = 0.103446 Ω

- Vdrop = 50 X 0.103446 = 5.1723 V,

- Percentage drop = 5.17 V of 110 V = 4.70 %

Application

Substation Battery Bank: Electrical substation uses a 110 V or 220 V DC battery bank system for supplying DC power to the protection relays, trip coils and closing coils of the circuit breakers. The substation SCADA, emergency lighting also uses DC power from the battery bank. DC cables are required for powering up these systems which must maintain the flame retardant and low smoke insulation properties under fault conditions adhering to IEC 60228 and IEC 60332.

Renewable energy systems: Renewable energy installation uses a 600 V, 1000 V and 1500 V DC rated cables which are UV resistant, weather protected, ozone resistant and halogen free. These cable operates in harsh outdoor environment carrying continuous DC current from various modules to inverter.

HVDC Transmission system: HVDC link uses specialized cables such as mass impregnated paper insulated cables and XLPE insulated cables. These DC cables are rated to operate at 320 KV up to 800 KV in modern power system. In these cables, the losses are extremely low with high insulation strength.

UPS in industrial system: UPS room in industries distributes 24 V, 48 V or 110 V DC supply for critical industrial processes, control rooms and IT systems.

Telecom and Data centers: Telecom and data centers uses 48 V DC distribution system for router, servers and power backup, where DC cables are used widely.

AC vs DC cable

| Parameter | AC Cables | DC Cables |

| Nature of Current | Alternating current changes direction 50/60 Hz | Unidirectional continuous current |

| Skin Effect | Larger conductor needed as current flows near the surface because of Skin effect | Smaller conductor needed as no skin effect is present, and thus, full conductor is utilized |

| Insulation Stress | Longterm stress is less because of alternating electric field. | Continuous electric field causes higher long-term dielectric stress. |

| Insulation Type | PVC/XLPE/EPR rated for AC RMS voltage | PVC/XLPE/EPR designed for continuous DC voltage |

| Dielectric Losses | Higher (due to frequency) | Very low or negligible |

| Voltage Rating Method | RMS-based (e.g., 0.6/1 kV, 3.3 kV) | Peak/continuous-based (e.g., 1.8 kV DC, 1500 V DC) |

| Shielding Requirement | Required for EMC, harmonic noise | Mostly for critical DC circuits; less issues of EMI |

| Armour Interaction | Armour can have induced current. | No induction → no armour heating |

| Capacitance/Reactance Effects | Important; affects cable sizing & length | None; only resistance matters |

| Voltage Drop | Depends on impedance (R + X) | Only resistance considered (R) |

| Fault Behaviour | High prospective short-circuit current; alternating arc | DC arc is harder to extinguish; higher arc persistence |

| Applications | LV/MV/HV distribution, motors, lighting | Substations, battery banks, telecom, UPS, PV solar, HVDC |

| Colour Coding | Brown/Black/Grey (phases), Blue (neutral) | Red (+), Black (−), Yellow/Green (earth) |

Common failures of DC cables

Polarity reversal: Polarity reversal occurs when the positive and negative conductors are interchanged by mistake during installation or maintenance, This change can instantly damage sensitive equipment like relay, charger, battery bank, inverter, etc. Hence, clear colour coding, polarity testing and labelled termination are needed to prevent this kind of accidents.

Overheating due to loose terminals: This can be caused because of loose lugs, improper crimped conductor, corroded terminals and high contact resistance, causing localized heating during current flow. Continuous heating will lead to insulation aging and fire risks. Periodic torque checks, proper crimping tools and thermal scanning are required to detect and prevent these failures.

Rodent damage: Rats and rodents chew the cable sheath, exposing the conductors and causing short circuits, ground faults and signal loss. Battery room, cable trench and solar fields are the high risk areas where these attacks are predominant. Therefore, the use of rodent resistant LSZH sheath and metallic conduits significantly reduces this risk.

UV degradation and insulation cracking at high temperature: DC cables are exposed often to sunlight in outdoor application. The UV radiation thus breaks down the sheath polymers and causes cracks and colour fading. This crack gives way to the moisture ingress resulting in cable failure. UV stabilized double insulated cables can be used for protection against the premature aging and failing.

High temperature environments and continuous thermal stress also makes the insulation crack allowing the moisture entry causing short circuits. Use of XLPE/EPR insulation and proper ventilation prevents the risk of thermal insulation damage in the DC cables.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.