Control cables are multi core cables ( 2 core or more), specially designed to transmit low voltage signals for the monitoring, protection, industrial automation and control of electrical equipment. In power system, control cable connects various relays, circuit breaker, switchgear, transformer and SCADA devices to ensure protection, operation and monitoring of the system via proper communication.

Control cables transmit the trip signals, status feedback of the equipment, interlock, alarms and also the input command. While power cable carries high current for delivering electrical power and instrumentation cable carries very low-level analogue or digital signals for measurement and control of the process, Control cable finds it’s place between the two, which is capable to handle moderate signal level with enhanced reliability, shielding to counter EMI and multi core flexibility.

Table of Contents

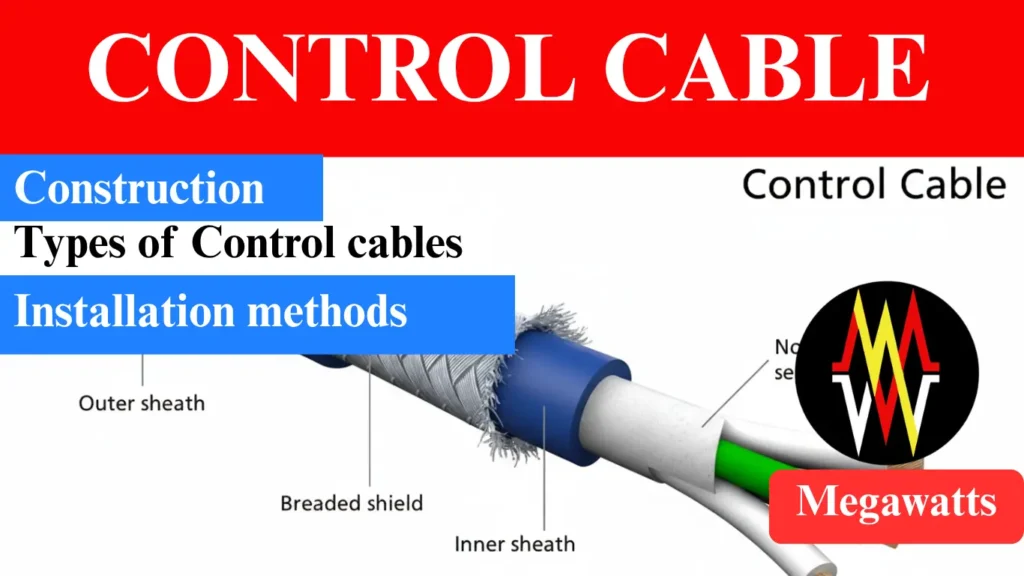

Construction

Conductor: The conductors of the control cable are basically made with copper with tinned or untinned surface treatment used specifically to enhance anti corrosive properties of the conductor. The conductors of the control cables are manufactured in class-2, which are annealed and stranded conductors with thick strands, recommended for fixed installations and class-5 conductors that are flexible and stranded with very thin strands, recommended for dynamic installation or installations with high bends. The high conductivity of these conductors ensures efficient transmission of signals with minimal voltage drop across long circuits.

Insulation: The control cables are basically insulated with extruded PVC or XLPE based on temperature rating and mechanical strength required. The PVC insulation offers higher flexibility, flame resistance and is economic while the XLPE insulation offers higher thermal endurance and excellent dielectric strength. It is the insulation which prevents the short circuit, maintaining the signal integrity and ensures the safe separation between adjacent cores in multi core control cable design.

Core identification: The cores of the control cable are identified using colour coding or number printed on it depending on the application of the cable and total number of cores. Colour codes are used for small core bundles for visual identification while number printing is preferred for higher core cables. Clear identification improves the installation accuracy while reducing wiring errors. It also eases out the maintenance related to the cables.

Inner Sheath: The inner sheath binds all the insulated cores of the cable into a compact assembly and provides a smooth bedding for armouring. Apart from providing protection to the internal cores from various stresses during bending and pulling, it ensures uniform shape of the cable with enhanced stability and prevents core damage during installation or operation. The inner sheath is usually made from PVC or PE.

Armour: These cables may include Steel Wire Armour (SWA) or aluminium armour in order to provide the cable mechanical protection against impact forces, rodents and crushing forces. The Steel Wire Armour (SWA) is used for heavy duty environments, where chances of impact forces are high, while the aluminium armour reduces the weight and risks of corrosion. Armouring also offers some electromagnetic shielding, with enhanced durability in industrial installations.

Outer Sheath: The outer sheath of the cable is usually made from PVC or LSZH for protection of the cable from moisture, UV radiation, abrasion, oils and chemicals. PVC offers an economic solution with durability, while LSZH is used where low smoke and zero halogen emission are the priority. The outer sheath forms the final barrier of the cable which provides the environmental protection and ensures long service life with operational reliability.

Types of control cables

Based on insulation: These cables uses extruded PVC or XLPE insulation, selected on the basis of the thermal rating required and mechanical strength required. PVC cables offers greater flexibility and flame resistance and is ideal for indoor use while the XLPE insulated cables provide higher temperature rating and better dielectric insulation best suited for industrial use and substations.

Based on Shielding: These cables are available in unscreened, foil screened and braided screen designs. Unscreened cables are general purpose cables used in control circuits, while the foil screens prevents low level signal interference. The braided screen provides best EMI protection in the industrial sector be it near VFD devices or substation.

Based on core count: Control cables come in a configuration of 2-cores to 61-cores. The number of core is chosen based on the number of signals or controls required. The common sizes used in substations are 12-core, 19-core, 24-core, and 37-core. Higher the core of the cable, lower is the routing complexity of the cable. Higher cores support multifunction panels and simplify the installation of the cable by bundling of multiple circuits in one cable.

Armoured vs unarmoured: Armoured control cables with SWA or aluminium armours are used in outdoor areas or underground for protection against mechanical impacts and rodent damage. While unarmoured control cables are used inside the control room, marshalling kiosks, where inside the panel, risk of impact forces are low and flexibility required is higher during termination of the cable.

Installation methods

Cable trays: Cable trays, ladder type or perforated trays are commonly used in the routing of the control cable in substations, industrial plants and buildings. The cable trays provide a good ventilation, ease of inspection and structured support for the cables. Ladder tray supports heavier cables, while perforated tray supports small multi core cables and allows better fastening and segregation of circuits.

Conduits and GI Pipes: These protects the control cables in the indoor pathways, panel room and sensitive areas. The conduits and GI pipes shield the cable from mechanical damage, moisture and chemical exposure. These are also fire resistant, ensuring safe cable routing through the walls or floors. Other than safety and protection, GI pipes and conduits provide clean and organised pathways for cable segregation.

Trench: Outdoor installation of the cables requires trenches where the cables are laid with proper sand bedding and protective covering. Sand provides cushion to the cable from sharp stone contact and maintains the thermal stability of the cable. Brick, concrete slab or market tapes may be installed over the trench for protection, making it reliable for long routes in substation, industries and utility networks.

Termination and Glanding: Brass, stainless steel or aluminium glands based on environment and cable types are used for termination of the control cable. Glands allows the mechanical retention and sealing while also providing the earthing continuity for the armoured cables. Ferrules and markers must be applied in each core for identification ensuring accurate connections.

Control cables used in substations with reference

| Substation Circuit / Application | Recommended Control Cable Type | Typical Core Count | Relevant Standard / Reference |

| CB Trip Circuit | 2.5 mm² Cu, PVC/XLPE insulated, armoured | 2C / 4C | IEC 60228 (conductors), IEC 60502-1 (LV cables), IEC 61850 (control functions) |

| CB Close Circuit | 2.5 mm² Cu, PVC/XLPE, armoured | 2C / 4C | IEC 60502-1; IEEE 525 (Substation Control Cable Guidance) |

| Breaker Auxiliary Contacts | 1.5 mm² Cu, PVC/XLPE, armoured or unarmoured | 7C / 12C | IEC 60502-1; IEEE 525 |

| Isolator Open/Close Commands | 2.5 mm² Cu, PVC/XLPE, armoured | 4C / 7C | IEC 60502-1; IEC 60445 (wire colour coding) |

| Isolator Auxiliary Switch Indications | 1.5 mm² Cu, PVC insulated, armoured | 12C / 19C | IEC 60502-1; IEEE 525 |

| Earth Switch Status & Commands | 1.5 mm² Cu, PVC/XLPE, armoured | 4C / 7C | IEEE 525; IEC 61850-5 (control & status signals) |

| Transformer Marshalling Kiosk Signals | 1.5 mm² Cu, PVC/XLPE, armoured | 19C / 24C / 37C | IEC 60502-1; IEC 60076-1 (transformer auxiliaries) |

| Relay to Panel Wiring | 1.5 mm² Cu, unarmoured, PVC | 4C / 7C | IEC 60204-1 (control circuits), IEC 60502-1 |

| CT Secondary Circuits | 2.5 mm² Cu, PVC/XLPE, screened (optional) | 2C / 4C | IEC 61869-2 (CT), IEEE C57.13 |

| VT Secondary Circuits | 2.5 mm² Cu, PVC/XLPE | 2C / 4C | IEC 61869-3 (VT/PT), IEEE C57.13 |

| SCADA / RTU Signals | 1.5 mm² Cu, Foil-Screened control cable | 4C / 7C | IEC 61158 (communication), IEC 60502-1 |

| Analog 4–20 mA Signals | 1.5 mm² Cu, foil/braided screened | 2C | IEC 60332 (fire), IEC 60502-1 |

| Panel Interlocking Signals | 1.5 mm² Cu, PVC/XLPE | 7C / 12C | IEC 60204-1, IEEE 525 |

| Protection Trip Transfer Between Panels | 2.5 mm² Cu, XLPE, armoured | 2C / 4C | IEC 61850-5, IEC 60255-27 (protection systems) |

| Alarm & Indication Signals | 1.5 mm² Cu, PVC/XLPE | 12C / 19C | IEC 60204-1 |

| Metering Circuits (low-voltage) | 1.5 mm² Cu, shielded (for noise immunity) | 2C / 4C | IEC 62053 (meters), IEC 60502-1 |

| Power Supply to Marshalling Boxes | 2.5 mm² Cu, XLPE, armoured | 2C / 4C | IEC 60502-1; IEC 60364 (LV wiring) |

| Annunciator/Alarm Windows | 1.5 mm² Cu, PVC | 7C–19C | IEC 60204-1 |

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.