An Electrical Fuse is a basic protection device which helps with protection of the circuit from overcurrent. Overcurrent in any electrical system is the flow of excessive current, higher than the rated current of the circuit. Overcurrent protection in any electrical system thereby detects and interrupts the excess current in the electrical circuit which can potentially cause damage to the electrical equipment, conductor and insulator. The overcurrent in a circuit occurs due to overloading, short circuit or ground faults.

The circuit interruption is achieved by the use of circuit breaker as well as fuse. Although both serves to interrupt the high current in the circuit, both differ in case of operation, cost and usage.

Table of Contents

What is a Fuse?

An electrical fuse is basically a protective electrical device which prevents the electrical circuit upon interruption from high circuit current exceeding the rated limit of the circuit, thus stopping the flow of current in the circuit.

Construction

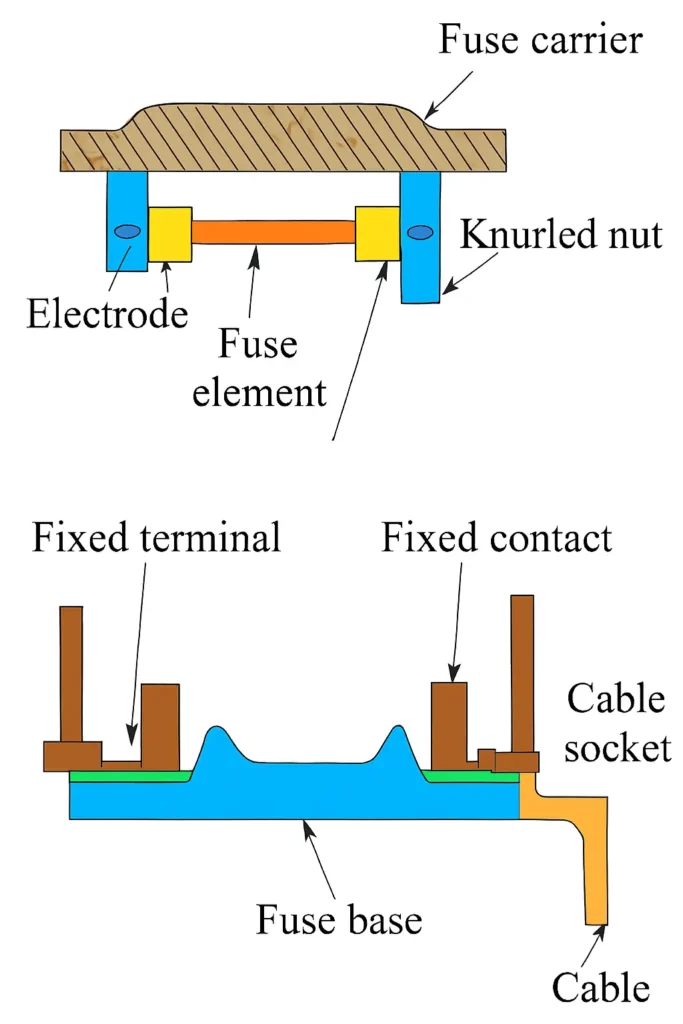

The electrical fuse assembly of an electric circuit essentially consists of Fuse element, Fuse body, End Terminals, and filler materials.

Fuse element: The fuse element is a metallic strip or a thin wire which is made up of tin, zinc, copper and silver alloy. The fuse element have low melting point and very stable resistance. The design of the fuse element is very specific as it remains intact under normal conditions but once, the rated current is exceeded because of short circuit or overloading of the circuit, it rapidly melts as a result of heating. As the fuse element melts, the circuit remains open and no electrical power flow is thereby possible.

Fuse Body: It is the enclosure which houses the electrical fuse element inside providing mechanical strength, electrical insulation and also absorbing the heat generated during the melting of fuse element. The body is generally made up of porcelain, glass or ceramics, which can withstand high temperatures and high electrical stresses. The body is so designed that the electrical arc, generated at the time of the melting of fuse element, is contained within the body. The body also supports the terminals for secure electrical connections.

Terminals: The fuse element is connected to the terminals which is present in the body. The terminals are metallic parts at the both ends of the fuse element, used to connect the fuse element to the electrical circuit. The terminal is basically a low resistance electrical path which also enhances mechanical support with ease of mounting and replacement of the fuse element. The terminals are basically made of copper, brass, silver plated metals for corrosion resistant properties and also enhance conductivity. The design of the terminals ensures minimal power loss, reliable electrical connection along with long service life.

Optional Filler Material: The filler material used in a fuse assembly which hugs the fuse element, majorly is present to quench the arc produced when the fuse element melts. The filler material also absorbs the heat generated during the faulty conditions. Silica sand, powdered quartz materials are most used filler materials because of their rapid cooling and deionizing properties which resists reignition of the arc providing a complete circuit interruption. Although the use of filler material is optional, its use enhances the breaking capacity, heat dissipation and safety of the fuse.

Working principle

The working principle of an electrical fuse is based upon the heating effect produced by electric current. Whenever electric current flows, it produces heat because of the resistance of the conductor. Similarly in the fuse element, under the normal conditions, the heat generated by electric current in the fuse element is dissipated to the surrounding body efficiently, thus retaining the fuse element intact.

But as the overcurrent or short circuit condition surfaces, the current flowing through the electrical fuse element increases drastically and following joule’s law H=I2Rt,( H=Heat, I=Current, R=Resistance & t=time) the heat generated is proportional to the square of the current flowing. Thus, there is a rapid increase in the temperature of the fuse element. When the current value exceeds the rated current of the electrical fuse, the generated heat at the fuse element becomes unbearably high for the entire assembly to dissipate it successfully and thus the fuse element melts away as the temperature reaches the melting point.

The electrical continuity of the circuit thus breaks with the melting of the fuse element, thereby interrupting the flow of current. This protects the connected electrical appliances to the circuit and the conductor from excessive damage and fire hazard.

The electrical fuse assembly thus operates automatically based on the circuit current level without any external aid. It is a simple, fast and economic protection against overloading and short circuit. Once a fuse operates to protect the circuit, the fuse element must then be replaced with a new one to restore the circuit.

Types of electrical fuse

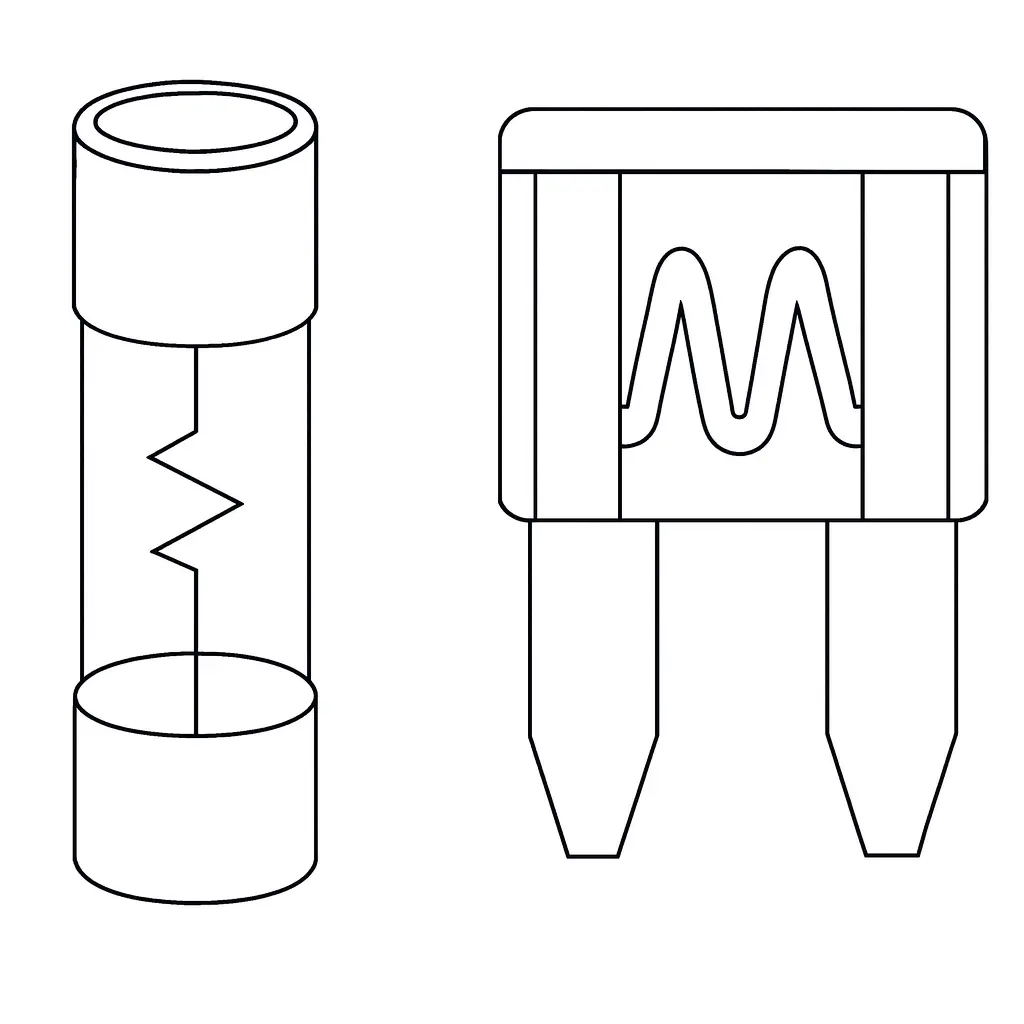

Cartridge Fuse: It is a cylindrical electrical fuse with a ceramic or glass body enclosure and metal endcaps. It contains filler material for efficient arc quenching. The most common application of these types of electrical fuses are in domestic and industrial panels. It offers reliable protection against overcurrent and associated faults. Because of its compact design, the replacement becomes easy.

Rewirable Fuse: Rewirable Fuse also called as Kit kat fuse comprises of a base and a carrier made up of porcelain which consists of the fuse wire, that is replaceable. When the fuse operates and the wire melts, rewiring becomes simple, fast and easy making it an ideal choice for domestic applications even though it is slower and less accurate in operation compared to cartridge fuse.

Blade Fuse: A blade fuse is the one which is housed in a plastic body with two metal terminals. These are most commonly used in automotive circuitry. These fuses are designed for compact fittings and easy plugin type installations and replacement. The fuse rating is indicated by the colour. These fuses provide overcurrent protection to the vehicle wiring and electronic system.

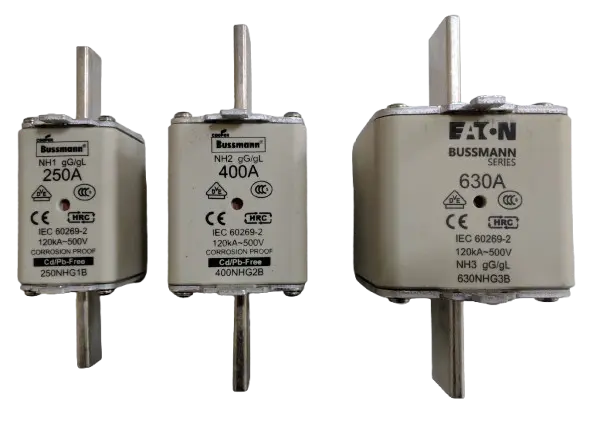

High Rupturing Capacity HRC Fuse: These are basically sealed ceramic fuse infused with silica and silver fuse element. It finds its application in high voltage and industrial applications, where fault current can be significantly large. These type of fuses can interrupt high fault current without explosion and arcing, while being fast-acting and reliable at the same time for efficient circuit protection.

Advantages

Simple Design: An Electrical Fuse has a very simple design and requires minimal components. It is easy to install, maintain without complex adjustments and mechanism.

Inexpensive: The most economical device for overcurrent protection is fuse. It is because of low manufacturing cost and minimal design. Compared to the cost of circuit breakers, it is a fraction of the cost of CB.

Very Fast Operation: The response time of fuse is almost instantaneous as the thin metallic fuse element melts within milliseconds at high fault current, thereby offering quick disconnection of the circuit.

Disadvantages

Single time Use: Upon operation of the electrical fuse in a circuit, it must be replaced, as the fuse elements melts permanently, for restoring the circuit.

Delay in power restoration: The power supply in the circuit remains interrupted until the blown out fuse is manually replaced. This causes delay in the restoration of power.

No indications: A fuse gives out no prior indication before and after blowing out hence it must be inspected with a multimeter to find the blown out fuse.

Fuse V/s Circuit breaker

| Fields | Fuse | Circuit Breaker |

| Working Principle | Heating effect of electric current | Tripping mechanism operates the contact |

| Usability | Single use | Reusable |

| Cost | Economical | Expensive |

| Indication | None | Has ON/OFF or Trip indication |

| Maintenance | Simple | Complex |

| Application | Small and domestic circuits | Industrial and large circuits |

| Response Time | Faster (1-2 ms) | Slower (10-100 ms) |

This article is a part of the Switchgear, where other articles related to switchgear are discussed in details.