Air blast circuit breakers are a fast operating circuit breaker in which the quenching of the arc is achieved by a blast of compressed air inside the interrupter chamber. These breakers are mainly used for high-voltage applications because of their high speed operation. These breakers are suited for repeated operations, auto reclosing having a unit-type multi-break construction, offering simple assembly and maintenance, etc. The air blast circuit breaker requires a compressor plant to maintain the required air pressure in the receiver.

Table of Contents

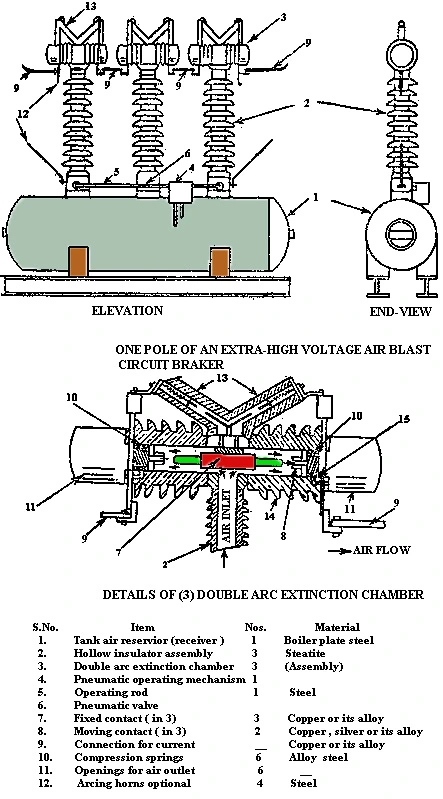

Construction of air blast circuit breakers

The other name of these breaker is compressed air circuit breakers where the arc generated during contact separation is subjected to a high pressure air blast. This blast of compressed air blows away the arc conducting ionized molecules and thus extinguishing the arc in 2 to 3 cycles. As the arc extinction process gets completed, the interrupter chamber gets filled with high pressure air, of around 30kg/cm2,which ensures that the arc does not gets re-established. Since the air under high pressure has more dielectric strength than air at normal pressure, the contact gap of these breakers can be as low as few cm.

In low-capacity circuit breakers, the isolators remain an integral part of the breaker which operates immediately after the circuit breaker providing an additional gap. But, in the EHV circuits, the isolators are independently mounted along with the air blast circuit breaker.

The air compressor system maintains a pressure of 20-30 kg/cm2 at the reserviour of the breaker. The reserviour is connected to the arcing chambers via hollow insulator columns directly fixed on the reserviour for each phase and are attached with valves. For maintaining sufficient electrical clearance from the grounded resirvoir, the arc extinguishing chamber is mounted on the top of the hollow insulators. The terminal of the breaker connects the arc extinguishing chambers in series per phase to the adjacent equipment terminal in the circuit.

Three double arc extinguishing poles connected in series per phase makes six number of circuit breaks per phase. The arc extinction chamber is designed to have twin fixed contact. The two moving contacts moves on the horizontal axis to make or break the circuit. This movement of the contacts is controlled by compressed air pressure and spring force.

The operating mechanism with manual or electrical signal moves the operating rod. This action of the rod opens the valves at the bottom of insulators and allows entry of high-pressure air through the hollow insulator, to the arc extinction chamber and strikes the moving contacts. Upon high built-up of air pressure beyond the spring force, which holds the contacts in closed position, the moving contacts opens up in a quick action. The travel of the moving contact is limited to short distance against the spring force and this movement also closes the outgoing port. Since the outgoing port is closed, the chamber fills up with pressurised air. While arcing is taking place inside the chamber, the air along the ionized particles moves through openings on the side.

While during the closing operation, the valve is closed via the electrical signal which cuts the flow of air to the extinction chamber. The pressure inside the arc extinction chamber drops to atmospheric pressure as the valve also connects the hollow insulator to atmosphere. This drop in air pressure makes the spring force dominant and the moving contacts closes, clinging to the fixed contact.

The opening and closing action is very fast because the it takes almost no time for the air pressure to built up in the extinction chamber as well as no time for the pressure to drop and the charged spring taking the closing action.

In 145 KV rated application, air blast circuit breaker essentially includes 3 arc interruption chamber in series, however in 420 KV installations, there are many more chambers connected in series. For low voltage application in LT installations, single interrupter unit is sufficient.

In high voltage applications, because of reactive loads, closing and opening resistors are used across the interrupter for limiting overvoltage during closing operation and to avoid restrike during opening operation.

Typical ratings of Air blast circuit breakers are: –

- 12 kV, 40 kA

- 22 kV, 40 kA

- 145 kV, 40 kA, within 3 cycle

- 245 kV, 40 kA or 50 kA, within 2 ½ cycle

- 420 kV, 40 kA or 50 kA or 63.5 kA, within 2 cycle

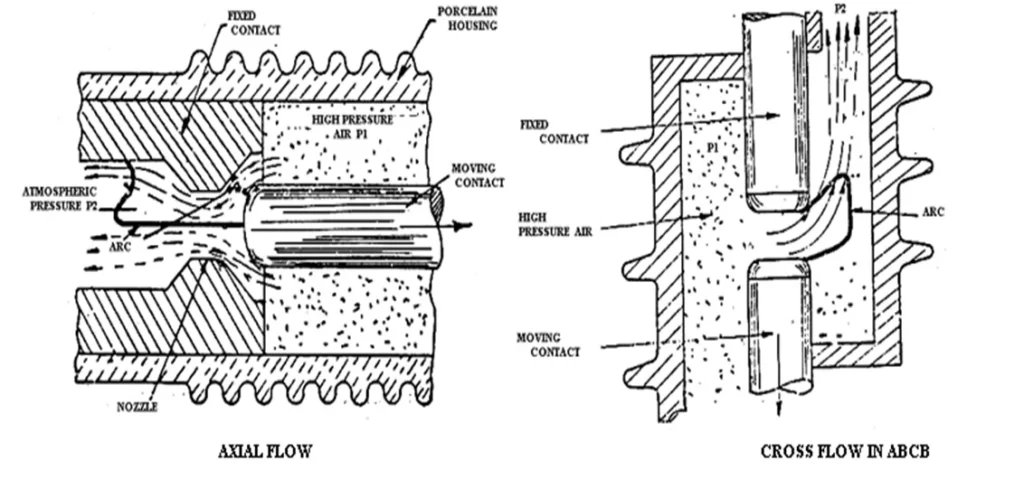

Axial blast-type breakers

In these breakers, the air flows through a convergent-divergent nozzle. The pressure difference and the design of the nozzle causes the air expands in the low-pressure zone, with almost supersonic velocity. The mass flow rate through the nozzle is a direct function of pressure ratio, area of the throat, nozzle throat diameter as well as the diameter of the arc to be quenched. This supersonic air cools the arc’s surrounding, reducing the arc diameter to almost zero at current zero. Instantly at this moment the arc is interrupted and fresh air is filled up in the chamber increasing the dielectric strength to avoid re-establishment of the arc.

Cross-flow type breakers

These breakers are basically used for a low voltage application. In cross blasts systems, the airflow pushes the arc, increasing the arc length. With the increase of arc length, the arc resistance increases and with continous flow of air, the arc gets extinctguished. Increased mass flow rate inside the interrupter results in high breaking capacity of the circuit breaker. The air pressure gets built up in the interrupter, increasing the dielectric strength and thus reducing chances of a restrike due to transient recovery voltage.

Merits Of Air Blast Circuit Breaker

- It can be used at high pressure.

- Reliable operation due to externally placed air reserviour.

- No decomposition as air is less reactive.

- Clean, non-inflammable.

- Free availablity of extinguishing agency.

- Air is new and replenished. Hence the breaker can be repeatedly operated.

- Higher the pressure, high is the dielectric strength, hence a small contact gap is enough.

- Mobility of the moving contact and fire extinguishment, both is achieved by the air.

Demerits of Air Blast Circuit Breaker

- Critical design of arc extinction chamber.

- Operation is complex,

- Additional requirements of closing resistors for closing due to switching overvoltage surges.

- Additional air compressor unit is required. which in other breakers is not required

- Complexities in storing and compressing the air at high pressure.

This article is a part of the Switchgear, where other articles related to switchgear are discussed in details.