Sweep Frequency Response Analysis or SFRA is a test which is used to assess the mechanical integrity of the transformer’s main part which is core, winding and clamping structure by injecting low voltage signals from few Hz to several MHz and measuring the response of transformer at various frequencies.

Table of Contents

Core idea of SFRA

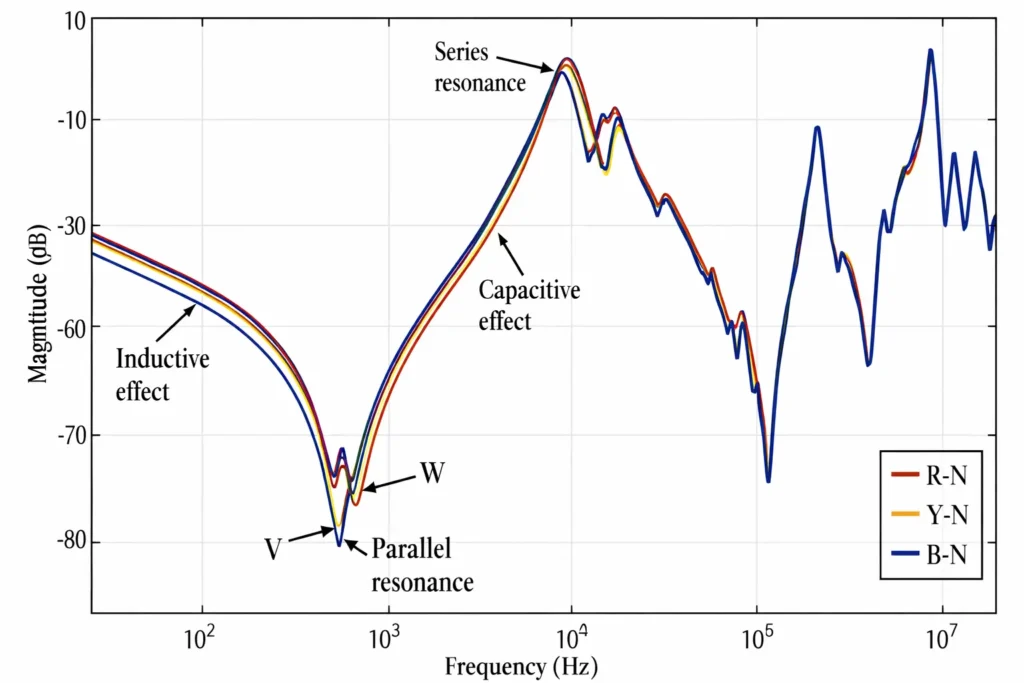

Each transformer behaves like a complex network of inductance, capacitance and resistance. Together it forms a unique electrical fingerprint. The SFRA test kit injects low-voltage signal that sweeps from a low frequency of 20 Hz to 2 Mhz and measures the response of the transformer. The measurement or curve, which is gain (dB) vs frequency (Hz) is plotted by the tester and is compared to the factory baseline records or previous test history.

Any mechanical deformation of the main part of the transformer changes the internal R-L-C network which shifts the frequency signature.

SFRA Test equipment

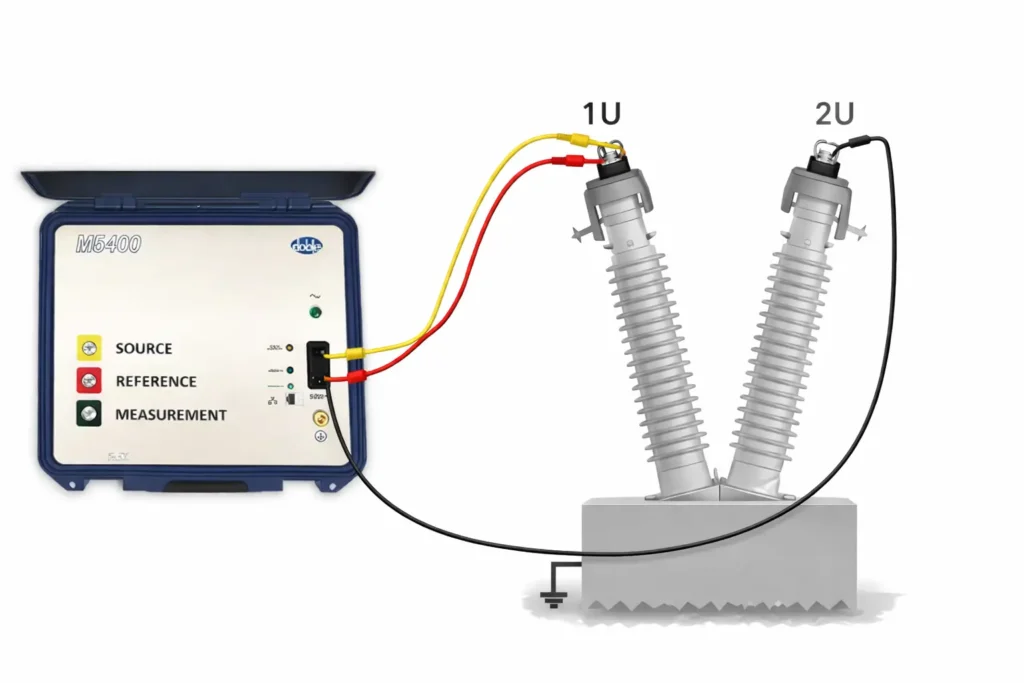

The SFRA test setup is built around a precision analyser, which injects and measures the frequency response with very high repeatability. The signal generator of the test equipment produces low voltage swept sine wave across wide frequency spectrum, which is recorded by the reference channel. The measurement channel captures the transformer’s response. The analyser compares both the signals and compute the transfer function.

Shielded coaxial cables are used in the test for preventing electromagnetic noise and ensuring stable impedance. A laptop with dedicated analysis software which has the baseline signature stored in it, overlays the past results over the current curve and highlights the deviation.

SFRA Test connections

Open circuit Connection

End to End (1U-2u): It excites the full winding resistance and detects axial displacement of the winding, winding compression or loosening, hoop buckling after short circuit, turn to turn deformation, winding collapse, core movement, clamping pressure change, bad lead connection.

Inter phase (1U-1V): It excites the mutual coupling between adjacent windings and detects radial displacement between phases, phase to phase winding movement, interphase insulation deformation, uneven clamping of winding assembly, core asymmetry, winding tilt.

Diagonal phase (1U-2v): It excites the longest coupling path and help detect the global winding distortion, major mechanical displacement, core-frame shift, structural looseness.

Short circuit SFRA

In this connection the HV or LV windings are shorted which supresses the magnetizing effects and forces the measurement to be dominated by leakage impedance and mechanical coupling between the windings. It detects radial winding displacement like HV bulging, LV winding collapse, loss of radial spacers.

Any change in the distance between HV and LV alters the mutual coupling. Short circuit SFRA detects the compression between windings, insulation barrier displacement, crushed pressboard cylinders, reduced mechanical stiffness, degraded clamping pressure.

| Feature / Fault Type | Open-circuit SFRA | Short-circuit SFRA |

| Main winding geometry fingerprint | Primary detection | Secondary |

| Axial winding displacement | Good sensitivity | Excellent sensitivity |

| Radial winding movement | Moderate | Very high sensitivity |

| Inter-winding spacing change | Limited | Primary detection |

| Turn buckling / hoop deformation | Moderate | Excellent |

| Short-circuit mechanical damage | Visible | Highly visible |

| Core displacement | Detectable (low frequency band) | Minimal sensitivity |

| Clamping structure looseness | Detectable | Detectable |

| Lead movement / tap lead shift | High-frequency band | Limited |

| Core-to-frame structural issues | Detectable | Not targeted |

| Transport shock damage | Detectable | Confirmatory |

| Leakage inductance variation | Indirect | Direct measurement |

| Magnetizing branch behaviour | Visible | Suppressed intentionally |

Test procedure

Step1: Deenergize the transformer and isolate it by disconnecting the winding terminals.

Step 2: Clean the bushing terminals.

Step 3: connect the SFRA leads as per test plan.

Step 4: Run Sweep phase by phase.

Step 5: Save reference traces and label data correctly.

Step 6: Repeat for all windings.

Test result evaluation

The SFRA interpretation is comparative and not absolute. The analyser does not provide pass or fail resistance values, instead the diagnosis is based on the curve matching to the factory acceptance test and any deviation indicates a mechanical or structural change. Evaluation can also be done by phase-to-phase comparison of the same transformer. Consistency is of more importance here than magnitude.

Fault localization by frequency band

| Frequency region | Sensitive components | Typical fault |

| Low frequency | Core & clamping structure | Core displacement, loose clamps |

| Mid frequency | Main winding body | Axial/radial winding deformation |

| High frequency | Leads & stray capacitance | Lead movement, insulation spacing change |

Red flags in SFRA traces

| SFRA red flag | What it indicates electrically | Likely mechanical issue |

| Shift in resonance frequency | Change in inductance/capacitance network | Axial or radial winding displacement, core movement |

| Amplitude deviation between phases | Loss of symmetry in transfer function | Uneven clamping, phase-to-phase movement |

| Missing resonance peaks | Suppressed natural resonances | Collapsed spacers, winding compression, structural damage |

| Flattened peaks | Reduced mechanical stiffness | Loosened winding assembly, degraded clamping pressure |

| Increased damping | Higher energy absorption | Free winding vibration, friction from shifted parts |

| Sudden curve discontinuity | Local impedance change | Broken support, conductor shift, internal mechanical fracture |

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.