Transformer core frame tank test is basically a insulation test which verifies the magnetic core of the transformer and its structural frame are insulated properly from the transformer tank. This test is performed to ensure that there is no unintended grounding path between the core assembly and the transformer’s tank except the designated single grounding point.

Most power transformer’s design has core intentionally grounded at one point only as multiple grounding point or accidental contact of the core with the tank can potentially cause circulating currents, localized heating, and insulation deterioration.

Table of Contents

Why is the transformer core grounded?

The transformer’s core is intentionally grounded to control the electrical potential. Although the core is insulated from the windings, it is placed in a strong alternating electric field. The capacitive coupling from the HV winding can induce a floating voltage in the core and if it is left ungrounded, the core can accumulate charge and discharge intermittently to the tank thus producing sparking and stressing the insulation. A solid single ground keeps the core and the tank at same potential and eliminates the risk.

Capacitive coupling occurs from both the winding, the dominant contributor is HV winding as it is governed by voltage stress and not by geometric distance.

Purpose of the core frame tank test

The purpose of the core frame tank test is to detect accidental core to tank contact, confirm insulation integrity of the core and verify that only one grounding point exists which otherwise will result in circulating current, localized heating and progressive degradation of the insulation. If there exists multiple earthing points (accidental), it will result in long term core damage and reduced transformer life. The core frame tank test is usually done during factory routine testing, site commissioning, scheduled maintenance inspection and after transportation or major overhaul to ensure mechanical integrity of the transformer.

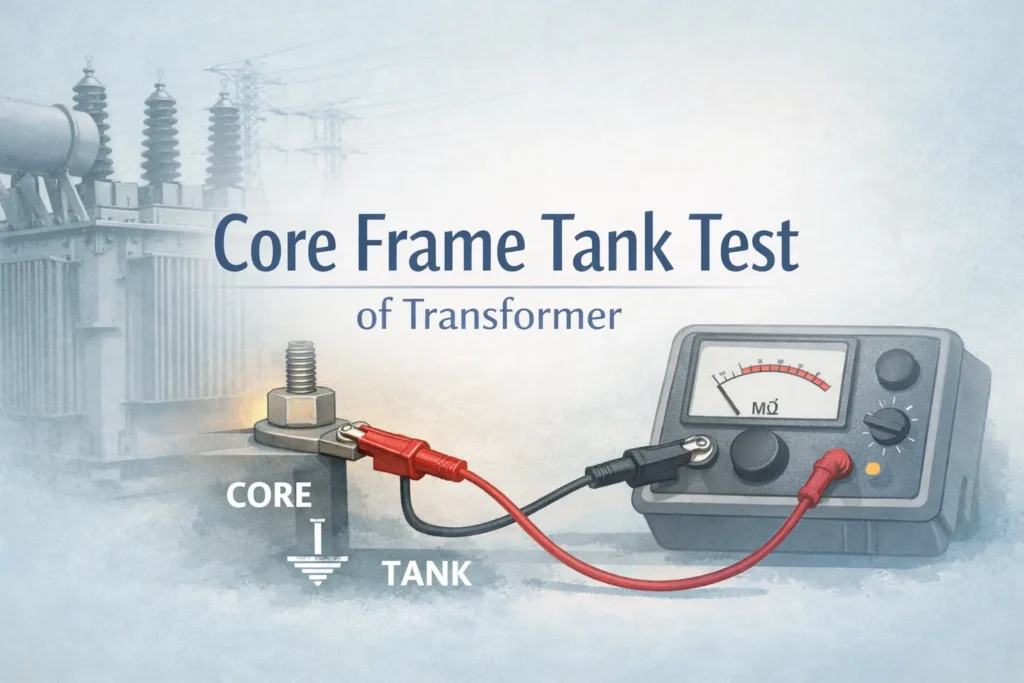

Test method

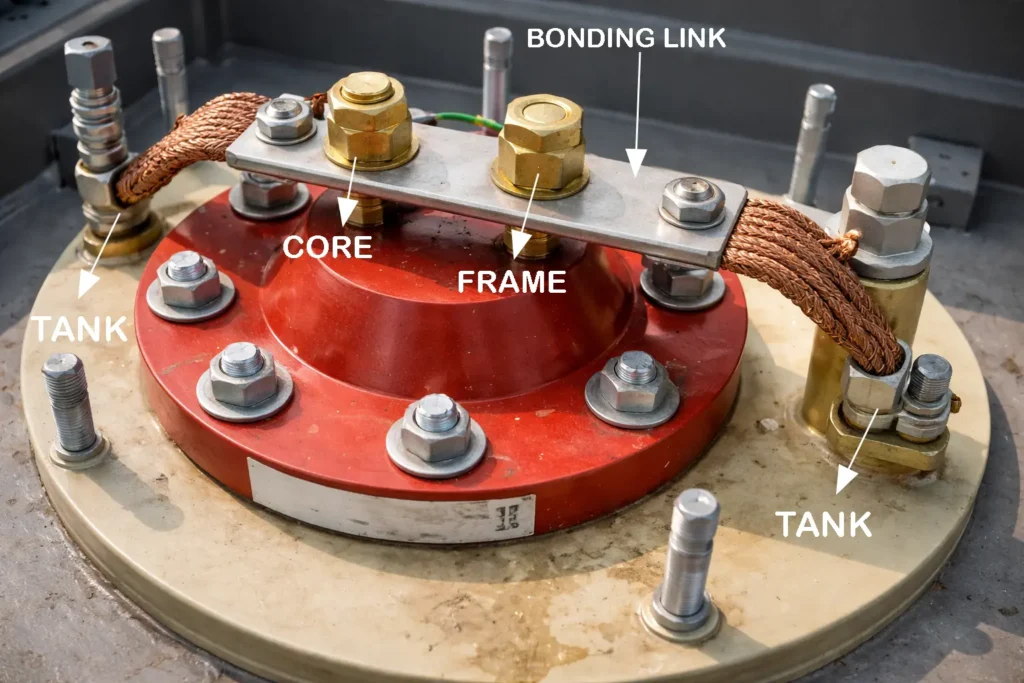

Step 1: Disconnect the intentional core frame tank bonding link inside the tank terminal.

Step 2: Apply test voltage using a insulation tester usually 500V or 1000V DC not more than 2500V.

Step 3: Measurement of insulation can be taken as core to tank, tank to frame or core to frame by connecting the leads of the tester with core or tank, frame or tank as necessary for 60 seconds.

Step 4: Record the test results.

Step 5: Reconnect the core frame tank bonding link.

Acceptance criteria

The core frame tank test results of all the connections must be above 100 MΩ or can be checked with respect to the factory acceptance test results. Values less than 10 MΩ indicates availability of second core grounding.

Interpretation of results

| Reading | Condition | Action |

| Very high resistance | Healthy insulation | Not Needed |

| Moderate resistance | Possible moisture | Monitor and Check DGA |

| Low resistance | Core contact suspected | Investigate immediately |

| Near zero | Direct short | Do not energize |

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.