The winding resistance test is the fundamental diagnostic test which is performed on power transformer in order to access the electrical integrity of the transformer winding, joints and tap changer (OLTC) contacts. By measuring the DC resistance of each winding and comparing it to the factory tests or previous test values, engineers can identify abnormalities like loose connection, contact deterioration, broken strands or shorted turns, which are not visible through routine inspection.

The winding resistance test is sensitive to the onload and off load tap changer conditions, which makes the winding resistance test essential part of commissioning, periodic maintenance and post fault investigation. Also because the resistance of the winding varies with the temperature, the results of the winding resistance tests must therefore be corrected to ensure meaningful comparison.

Table of Contents

Working principle of transformer winding resistance test

The winding resistance test is based on the principle of ohm’s law, where the resistance of the transformer’s winding is determined by applying a known DC current and measuring the resulting voltage drop across the winding. The resistance is calculated as R = V/I. Direct current is used in the winding resistance test because of inductive reactance that would be present otherwise with AC measurements, which would affect the measurement accuracy.

During the winding resistance test, a controlled DC current is injected into the winding. Because the transformer’s winding has high inductance, the current does not reach a steady state value immediately, it rises gradually as the magnetic core becomes magnetized. Accurate resistance measurement is then taken only after the current and voltage stabilizes, indicating the transient effects have decayed.

For low resistance windings, a four terminal measurement technique is employed also known as kelvin bridge, to eliminate errors due to test lead and contact resistance. The measured resistance reflects the conductor resistance of the winding along with the resistance of the joints, brazed connections and tap changer contacts in the current path.

Temperature correction in the winding resistance test

Temperature correction is required in winding resistance test because the electrical resistance of the transformer windings varies directly with the temperature. Since the copper and aluminium conductors have a positive temperature coefficient, resistance increases as the temperature rises. If measurements taken at different temperatures are compared without temperature correction, the results can be misleading and falsely indicate defects.

The formula for temperature correction is

- Where, Rs is the resistance at desired temperature,

- Rm is the resistance measured

- Ts is the desired reference temperature,

- Tm is the temperature at which resistance is measured

- Tk = 234.5 °C for copper, 225 °C for aluminium and 230 °C for alloyed aluminium.

During on site testing, temperature correction is rarely practised because the measurements are mainly compared between different phases.

Measurement of winding temperature

It is very difficult to measure the winding temperature accurately under field condition, but commonly used estimation includes the following

If the transformer has a winding temperature gauge, use it’s reading,

If the winding temperature gauge or WTI is not available, the winding temperature is assumed to be same as the oil temperature as displayed at OTI

If the transformer is tested without the oil, the winding temperature is normally assumed to be same as the temperature of the surrounding air or ambient temperature.

Test connections

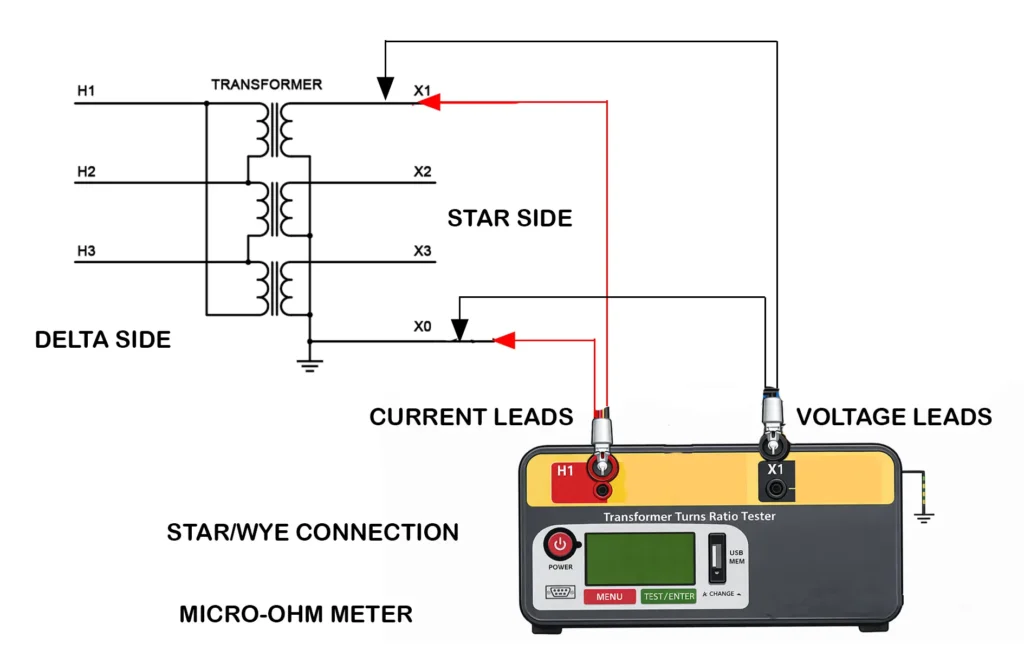

Wye or star winding

In a wye connected winding, the winding resistance measurement can be taken in two ways, viz terminal to terminal and terminal to neutral. When the measurement is taken terminal to neutral, each reading directly represents the resistance of one phase winding. It is the most common method to take the winding resistance test in why connected windings.

However, if resistance is measured terminal to terminal or phase to phase, the measured resistance includes two phase windings in series. Hence, in this case the measured resistance has to be divided by ‘2’ to derive the winding resistance of one phase.

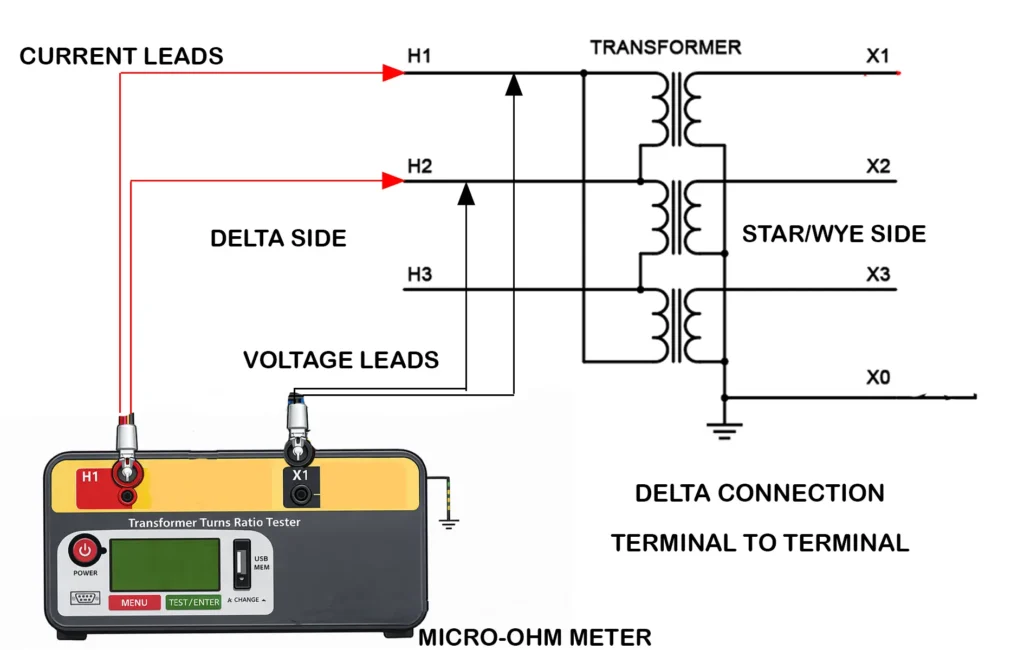

Delta windings

In winding resistance test of a transformer connected in delta, the winding resistance test can be performed in two ways.

Open delta method

The delta connection is opened at one point, which allows the individual phase’s winding resistance to be measured directly from terminal to terminal or phase to phase, with each measurement representing one phase winding.

Delta closed method

When the delta is not opened or it remains closed, terminal to terminal measurement includes one phase winding in parallel with other two windings. This results in a lower measured value than the true phase winding resistance. Therefore, to obtain the correct phase winding resistance, each measured winding resistance has to be multiplied by ‘1.5’. The factor 1.5 mathematically corrects the parallel current path inherent in a closed delta connection.

Autotransformer windings

The autotransformer consists of series and common windings, which shares electrical connections. It is because of this, the winding resistance is measured in two steps

Series winding resistance

The current injection path is between HV terminal and neutral and voltage measurement path is between HV terminal and LV terminal. This ensures that the measured voltage drop corresponds to series winding portion only.

Common winding resistance

Here the current path is between HV terminal and neutral and voltage are measured between LV terminal and neutral. Although current flows in both series and common windings, the voltage drop is measured only across the common winding. Thus, the measured resistance only corresponds to the common winding.

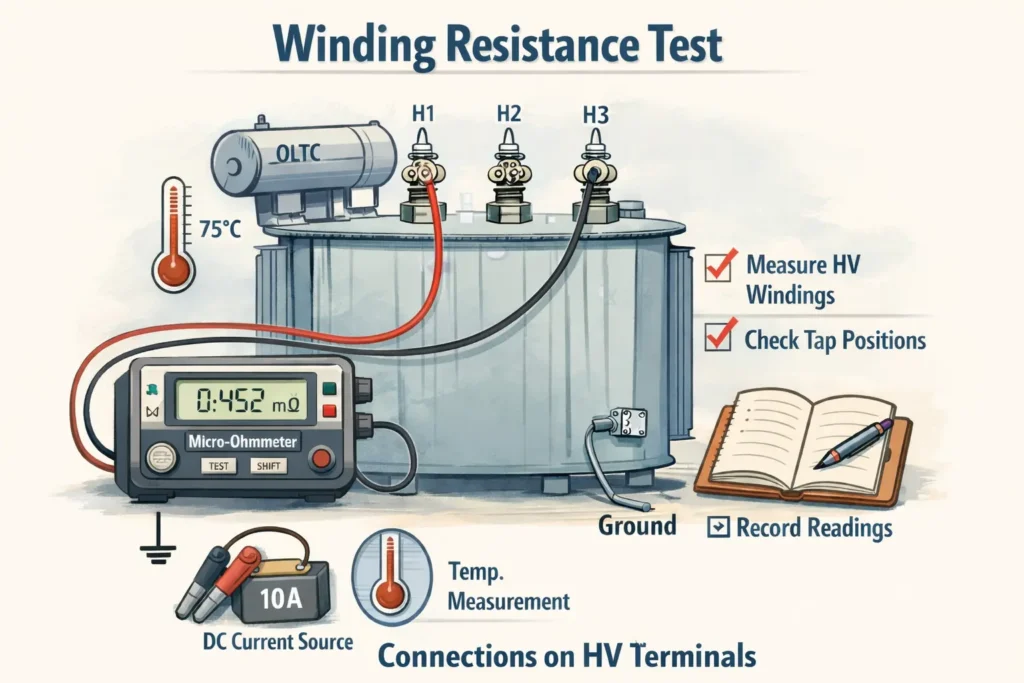

Procedure of winding resistance test

Step 1: De-energize the transformer and completely isolate it from the power system.

Step 2: Disconnect the HV, LV and neutral conductors.

Step 3: Make sure that the transformer’s body is grounded.

Step 4: Clean and dry the bushing terminals.

Step 5: Ensure the test connections, current injection phase to phase or phase to neutral as per transformer configuration and voltage measurement connection.

Step 6: Fill up the test details including winding temperature with the tap position details on the micro-ohm meter by powering it on.

Step 7: Press the start button and after few seconds the transformer will demagnetize automatically and the screen of the instrument will display the measured current, voltage drop and resistance at ambient temperature and resistance at 75 C (reference temperature). Record the same.

Step 8: Upon the completion of test, ensure the winding is discharged before disconnecting the test leads.

Step 9: Repeat for other windings.

Importance of demagnetizing a transformer’s core

Whenever a transformer is isolated from the power system, some magnetism could be retained by the core because of the phase shift which is also termed as residual magnetism. During DC winding resistance test, the DC current forces the magnetic dipoles to align in one direction (which are otherwise randomly oriented) and saturates the core. After the test when DC is removed, this dipole tends to stay aligned, resulting in core retaining a level of magnetism. During energization, this magnetism causes the core to reach saturation faster, thus decreasing the ability to store magnetic flux with drop in the inductance of the transformer offering less resistance to the flow of current, resulting in high inrush current.

Acceptance criteria

Phase to phase comparison is usually enough in the field for evaluating transformer winding resistance test. The measured resistance values of the three phases taken at same tap position and temperature should be within 2% of each other as recommended by IEEE C57 guidelines. Deviation beyond this limit can indicate problems like loose connections, damaged conductors and warrant further investigation.

While comparing the field values of winding resistance to the factory acceptance test, it is necessary to convert the field values to resistance values at reference temperature usually 75 °C. Since, it is difficult to exactly estimate the winding temperature, values within ±5% of the factory results are normally acceptable as per IEEE C57.

This article is a part of the Testing and commissioning page, where other articles related to topic are discussed in details.