A static var compensator is a high speed, power electronic based reactive power control device which is designed to regulate voltage and improve power quality in transmission and distribution networks. The static var compensators are installed at substation or critical grid nodes to dynamically adjust the reactive power flow by rapid injection or absorption of reactive power in response to system voltage fluctuation. Unlike the capacitor bank or synchronous condenser, the static var compensator provides fast, continuous and automatic control of the reactive power.

Table of Contents

Construction of static var compensator

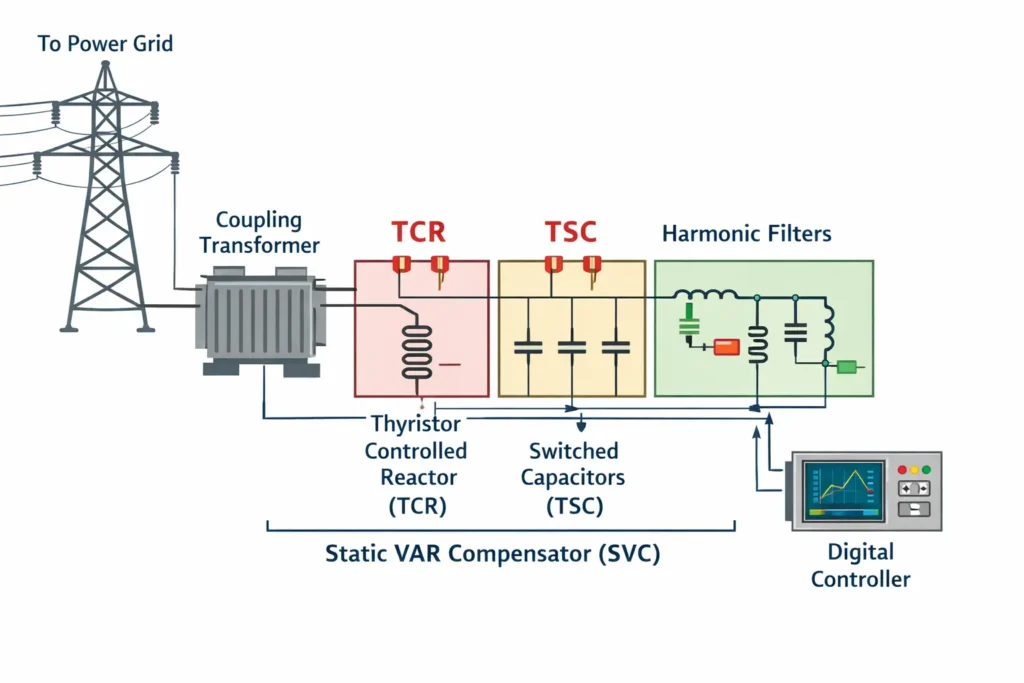

The static var compensator comprises of many key structural and electrical components which enables fast and continuous reactive power adjustment without moving parts.

Step down transformer

In the static var compensator, the coupling transformer or the step down transformer is the interface between the high voltage power system and the low voltage power electronic equipment like thyristor switched capacitor, filters and thyristor switched reactor. These operates at a much lower voltage level 5-30 KV compared to the system voltage 132-765 KV. The transformer steps down the system voltage to operating voltage of the static var compensator components and allows for economical and safe design of the components.

The transformer also provides the galvanic isolation to the static var compensator components from the power network, protecting the thyristor valves, control electronics and auxiliary systems from the grid faults and surges.

Thyristor controlled reactor

It is the controllable inductive branch of static var compensator which is built as a series combination of high power air core reactor and thyristor valve assembly supported by cooling, protection and control systems. This assembly is installed in the static var compensator as three identical single-phase branch, one for each phase normally in delta configuration for 3-phase supply.

Thyristor switched capacitor

The thyristor switched capacitor forms the capacitive branch of the static var compensator, supplying step controlled capacitive reactive power, thus allowing the SVC to support voltage during heavy load and system disturbance. Each thyristor switched capacitor branch is built as a capacitor bank switched by a thyristor valve assembly along with associated protection, control and damping equipment. By switching different branch of TSC in and out, the static var compensator can adjust the capacitive VAR output.

Harmonic Filters

Harmonic filters are essential components of the SVC which is installed to supress the harmonic currents generated by the thyristor switching in TCR and TSC branches. These harmonic filters are typically constructed as a tuned LC network designed for 5th, 7th,11th and 13th harmonic orders. It consists of power capacitors, air core reactor, damping resistors. In addition to harmonic suppression, the filter also supply a significant portion of the system’s fixed reactive power.

Thyristor valves and cooling systems

The thyristor valves forms the power electronic switching core of the static var compensator. It controls the current flow in the TCR and TSC branches. Each thyristor valve consists of series connected high power thyristor with voltage grading components, snubber circuit and fiber optic firing interface housed in the air insulated cubicle or sf6 enclosure.

Looped deionized water cooling with redundant pumps and heat exchangers are installed for large static var compensators with temperature supervision as high conduction losses and continuous current operation mandates independent cooling system. The smaller systems uses forced air cooling to ensure reliable and long term operation of the valve assembly.

Control and protection

The control system of the SVC uses a digital controller which forms the central intelligence unit of the system. It is responsible for fast voltage regulation, system stability and equipment protection. It continuously monitors the bus voltage, current, frequency and harmonic content and calculates the required reactive power output. Based on these measurements, the controller generates precise firing pulses for the thyristor valves of the TCR and TSC.

The protection system includes overcurrent, overvoltage, unbalance, thermal supervision, misfire detection, cooling system monitoring and fault isolation. The control and protection essentially include redundant digital controllers, protection relay and HMI for secure and reliable operation.

Auxiliary and switchgear components

Auxiliary and switchgear components include high voltage circuit breakers, isolators, earth switches, current and voltage transformers, surge arresters and necessary components required for the bay of static var compensator. This helps in safe operation, control and maintenance. The auxiliary system includes AC, DC auxiliary supply and communication equipment for reliable operation under normal and emergency condition.

Working principle

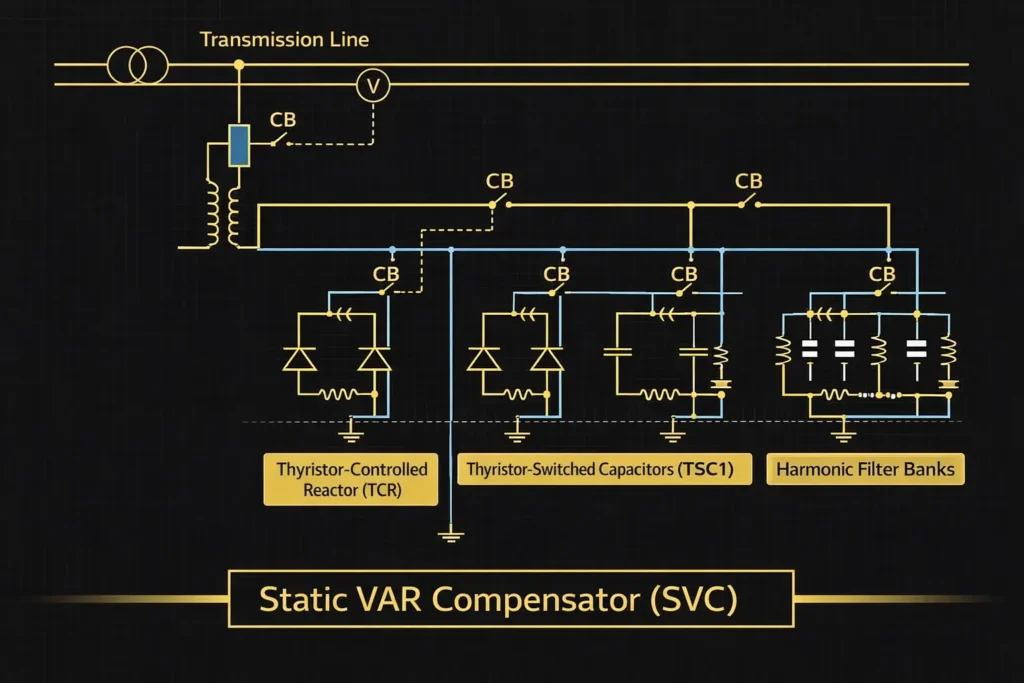

The static Var compensator is a shunt connected device that provides fast and continuous control of reactive power and regulates the transmission system voltage. The main function of this device is to maintain a stable bus voltage under continuous changing load and network condition. It achieves this by dynamically absorbing or generating reactive power through co-ordinated action of its main components viz Thyristor controlled Reactor TCR, Thyristor Switched Capacitor TSC and harmonic filter banks.

The SVC is connected to the power system through the coupling transformer and it continuously measures the bus voltage, current, frequency and harmonic content. The measurement is then processed by the digital controller of the SVC which compares the actual bus voltage to a predefined reference value. Any deviation from the reference value immediately triggers corrective measures.

When the system voltage rises above the desired level, the controller increases the conduction of the TCR by adjusting the firing angle of the thyristor valves. This causes the reactor to absorb more inductive reactive power, thereby reducing the bus voltage. Alternatively, when the system voltage drops, the controller switches in additional TSC branches thereby injecting capacitive reactive power into the system to increase the bus voltage. The TCR and TSC operates together providing both continuous fine control and step wise rough control of reactive power.

The harmonic filter plays a dual role of absorbing the harmonic currents generated by the thyristor switching and also supplies a portion of system’s fixed capacitive reactive power. The control system of the SVC continuously optimises the combination of TCR and TSC switching and achieves faster voltage stabilization, flicker reduction and damping of power system oscillation.

Failure modes

Thyristor valve failure

The thyristor valves degrade dur to thermal cycling, overcurrent stress and repeated switching transients. It leads to junction damage, misfiring and short circuit failure. Protection system detects abnormal current, temperature rise or firing loss and thus blocks the valve immediately and isolates the effected branch with alarms to prevent the cascading damage.

Capacitor bank damage

The capacitor bank degrades from the dielectric aging, over voltage stress, harmonic loading and internal heating. Over time, the insulation weakens and results in increased losses, partial discharge or catastrophic dielectric breakdown. Unbalance protection, operation of fuse and thermal monitoring helps in isolating the failed units before the extensive damage spreads through the entire bank.

Reactor’s thermal stress

The TCR and harmonic filter’s reactor experiences high current and harmonic loading causing the conductor to heat and endure mechanical vibration and weakness in insulation. If the thermal stress persists for long time, it accelerates the aging of the support materials and insulation systems, eventually leading to turns fault or ground fault. It is detected by temperature sensors and differential protection.

Control system malfunction

Control system failure comes from software bugs, processor faults, aging electronic components or communication link interruption. These can easily disrupt the firing command, cause loss of voltage stabilization or trigger false tripping. Redundant digital controller and communication monitoring help limit the downtime.

This article is a part of the Energy storage and reactive power compensation page, where other articles related to the topic are discussed in details.

Reference links

https://www.electricaltechnology.org/2023/02/static-var-compensator-svc.html