Pumped storage hydropower is basically a large-scale energy storage technology which is used to balance the generation and demand in the power system. The basic idea of pumped storage hydropower is to raise the potential energy of the water by pumping action from a low reservoir to high reservoir during low power demand or excess generation specially at night and then releasing the stored water back through turbine to generate electricity like a conventional hydro-electric plant during the peak demand hours.

In modern grids with increasing renewable energy integration, pumped storage play’s critical role in providing grid flexibility, frequency regulation and peak load management as the pumped storage hydropower has inherent fast ramping capability while being highly reliable and long service life compared to battery energy storage solutions. With a round-trip efficiency of about 70-85% the pumped storage hydropower is the most mature and proven form of bulk energy storage worldwide. The pumped storage hydropower can store hundreds of Megawatts of energy, essential for maintain stability and supporting renewable rich power systems.

Table of Contents

Working principle of pumped storage hydropower

Pumped storage hydropower operates on highly effective energy conversion principle, which enables large scale storage and recovery of electrical energy.

Pumping mode

In the pumping mode of the plants operation, it functions as a load on the power system. During off peak hours or during surplus generation like high solar or wind output, the electric motors drive the reversible pump turbines, which lifts water from a lower reservoir to higher reservoir. This process converts the electrical energy into potential energy stored in the elevated water. The pumped mode is made operational only at the off-peak hours as it allows the utility to absorb the excess power generation while maintaining system balance and stable frequency.

Generating mode

In the generating mode of the plant, the above process is reversed to support the peak load. Water from the high reservoir is released through the reverse pump turbine, which now operates as hydraulic turbines. The turbine converts the stored potential energy of the water into mechanical energy, which is converted back to electrical energy by the generator coupled to the turbine shaft, providing rapid and controllable power output.

The energy conversion cycle involves electrical energy → mechanical energy → potential energy during the pumping mode and potential energy → mechanical energy → electrical energy during the generating mode. Because of the hydraulic, mechanical and electrical losses not all input energy is fully converted back. Hence the typical round-trip efficiency, which is the ratio of energy output (discharging) to energy input (charging), for pumped storage hydropower is in the range of 70-85%.

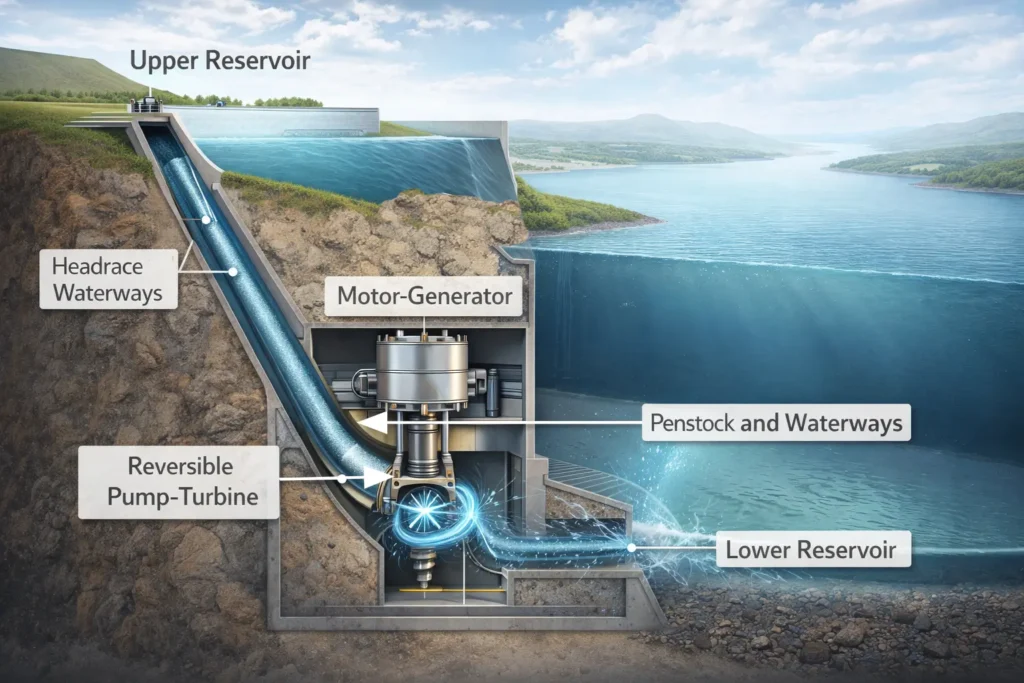

Major components of the pumped storage hydropower

Upper and lower reservoir

The upper and lower reservoirs form the core of the energy storage system of the pumped storage plant. The upper reservoir stores the water at a higher elevation, where the elevation difference related to the lower reservoir represents the stored potential energy. This elevation difference or hydraulic head directly determines the energy capacity of the plant. The design of the reservoir considers usable storage volume, lining, seepage control, sedimentation, and environmental constraints. The reservoir levels, water flow and operating limits must be carefully controlled so that the pumping and generating cycles are performed efficiently, while ensuring long-term availability of the plant without compromising the safety.

Reversible pump turbine

The reversible pump turbine is a dual function hydraulic machine, which can operate as a pump in the pumping mode, lifting the water to the higher reservoir and as a turbine in the generating mode, converting the water head into mechanical rotation. Modern design uses Francis type pump turbines to ensure optimise performance under variable head conditions. Hydraulic efficiency, less cavitation and smooth mode transition are the key design consideration, influencing reliability and performance.

Motor-Generator

The motor-generator is a single electrical machine which operates as a motor during the pumping mode, it draws power from the grid to drive the reversible pump turbine. While in generating mode, it converts the mechanical energy from the reversible pump turbine’s shaft into electrical power and exports it to the grid. Large synchronous motor-generators are usually used providing excellent voltage control, reactive power support, and grid stability.

By adjusting the rotor excitation current, the machine can operate in over and under excited mode, supplying capacitive VAR and increasing the bus voltage and absorbing inductive VAR and help reducing the over voltage respectively. Besides, synchronous machine contributes to rotational inertia stabilizing the grid frequency during grid disturbances by resisting the speed change.

Penstock and waterways

Penstock and waterways guide the water between the reservoirs and the reversible pump turbine. This includes intake structure, headrace tunnels, pressure shafts, penstock, and tail race tunnels. The design of these elements aims to minimize hydraulic losses, control transient pressures and ensure structural integrity under rapid flow reversals. The water hammer analysis, surge tanks and pressure relief measures are critical specially during the mode change.

Power house and switchyard

The power house houses the reversible pump turbine, motor-generator, auxiliary systems and control equipment. It can be underground design or surface mounted depending on the topography and environmental considerations. The power house layout must ensure safe operation, maintenance access and vibration control.

The switchyard connects the plant to the transmission network through step-up transformers, circuit breaker and protection system which enables synchronization, isolation and reliable power evacuation.

Types of pumped storage hydropower

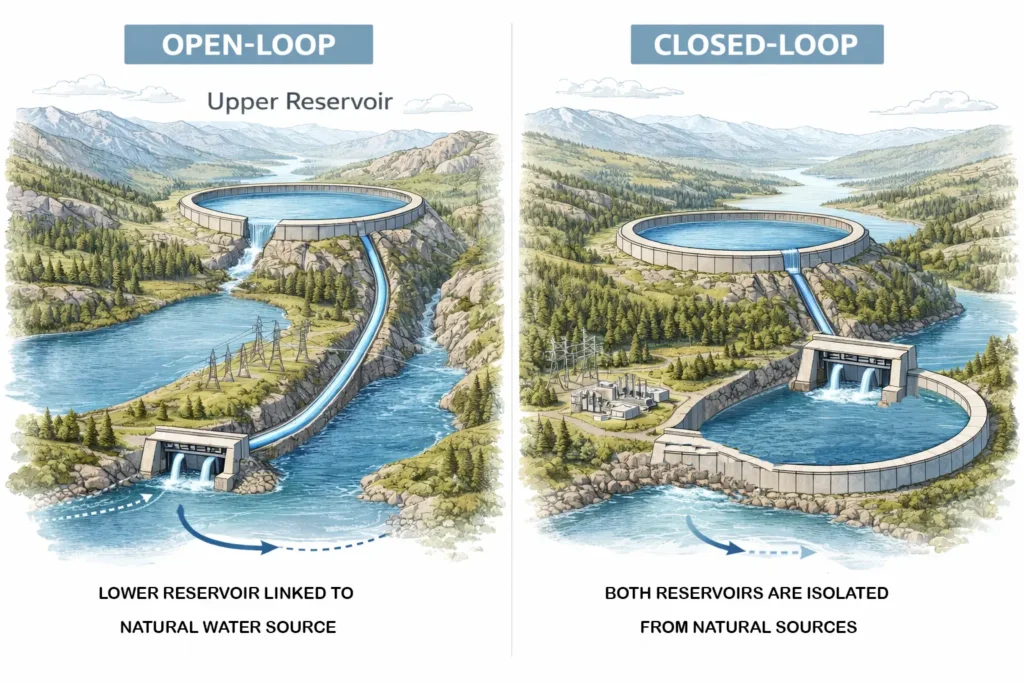

Open loop pumped storage

In this scheme the system is directly connected to the natural water source like river, lake or reservoir. The upper or lower reservoir interacts with the flowing water system making the availability and hydrological cycle of water a key design consideration. Existing water bodies saves the effort of developing reservoirs resulting in lower initial cost. This system often is integrated with the conventional hydropower system but with stricter regulatory constraints.

Close loop pumped storage

This system uses two purpose-built reservoirs with minimal natural inflow of water. The water is recycled between the reservoirs, offering good operational forecast, simpler environmental restriction and greater flexibility for renewable integration. This system is much more preferred for modern grid scale storage application.

Underground power house type

In underground power house arrangement, the reversible pump-turbines and motor-generators are housed in excavated parts within rocks. This configuration allows for higher hydraulic heads, reduced visual impact and improved structural stability because of natural confinement and bearing support provided by rock mass but involves complex civil works.

Surface power house type

Here the power house is constructed near the lower reservoir. This system is simple to build and maintain, are suitable for lower water head applications and cost effective. The choice however depends upon the water head, geology, and project economics.

Variable and fixed speed pumped storage hydropower

Fixed speed system uses a synchronous motor-generator which operates at a constant speed, providing reliable and proven performance with limited flexibility during pumping. The power input is largely fixed by hydraulic conditions. However, the variable speed type employs power electronic converters or doubly fed machines which decouples the hydraulic turbine-motor’s speed the fixed grid frequency allows for adjustable pumping power and finer frequency control. The rotational speed can be varied within a range of +/- 10-15 % of the synchronous speed. This type enables better grid balancing, improves overall efficiency, mitigates hydraulic loss and mechanical stress and enables better renewable energy integration although at a higher capital cost and system complexity.

Grid applications

The pumped storage hydropower provides many critical grid services which are essential for reliable power system operation. It enables peak load shaving by shifting energy from off peak periods to peak load hours where the demand is very high, thereby reducing the need of expensive peak power generation. Because the pumped storage hydropower has a large capacity and is capable of fast response, it offers effective frequency control and inertia support stabilizing the grid frequency during disturbances.

The pumped storage hydropower also plays critical role in renewable energy integration by absorbing surplus power from solar and wind generation and supplying back during periods of low renewable output. Also, it acts as a spinning reserve which remains synchronized with the grid and is ready to deliver power instantly. Many pumped storage hydropower installations have back start capability, meaning it can start and generate electricity without requiring external auxiliary power supply from the grid for control system during widespread outages. The back start is usually achieved by small hydro units energizing the control system.

This article is a part of the Energy storage and reactive power compensation page, where other articles related to the topic are discussed in details.