Dielectric loss in capacitor bank refers to the dissipation of real power in the insulating dielectric material of the capacitors, when it is energised with AC voltage. The dielectric loss in capacitor bank is quantified by the loss angle δ or commonly by tan δ, which is the ratio of the resistive component of the current to the capacitive (reactive) component of the current. A lower tan δ value indicates a healthier and lower dielectric loss in capacitor banks.

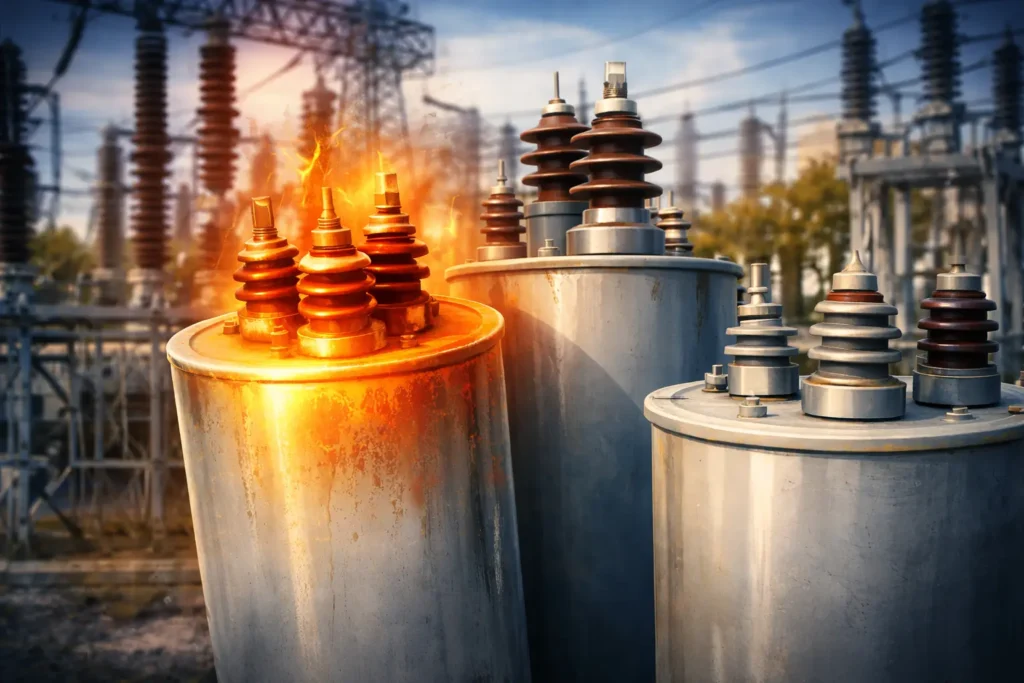

Physically the dielectric loss in capacitor bank indicates the energy absorbed in the dielectrics because of molecular polarisation and internal friction as the electric field alternates. The absorbed energy is then converted to heat elevating the temperature, accelerating aging and eventually degrading the insulation of the capacitors, if losses become excessive.

Dielectric loss differs from the resistive loss as it doesn’t occur in conductors or terminals but within the dielectric material itself. Dielectric loss are voltage dependent and are closely linked to the quality of the dielectrics, moisture ingress, contamination and aging.

Table of Contents

Sources of dielectric loss in capacitor banks

Dielectric materials

The dielectric materials directly influence the dielectric loss in capacitor banks, as they govern the polarization behaviour. Metallized polypropylene film is widely used because of its low intrinsic loss factor at fundamental frequency. However, the losses increase with the temperature, electric stress, and harmonic voltage content. Oil impregnated film capacitors introduce additional dielectric losses because of finite conductivity of the oil which conducts the leakage current, in phase with the voltage and dielectric relaxation characteristics.

Under distorted waveforms, the electric field contains multiple frequency components. Each harmonics forces the dielectric dipoles realign at different rates, in attempt to follow the rapid field reversal, it experiences phase lag between the polarization and electric field. Because the dipole orientation is not instantaneous, the lag increases the energy dissipation. At higher frequencies, the harmonic component, polarization becomes incomplete and delayed resulting in increased lag leading to increased tan δ and internal heating.

Manufacturing tolerance and impregnation quality

The manufacturing quality directly impacts the dielectric loss characteristics. Variation in film thickness causes the electric field intensity to increase locally which results in localized stress and higher dielectric loss. Electrode edge misalignment creates sharp electric field gradients causing local hotspots and accelerated aging and contributing to dialectic loss. Uneven winding tension causes wrinkles and airgaps and compression of dielectric layers resulting in reduced dielectric thickness, partial discharge sites and increasing dielectric losses.

Poor impregnation quality leaves micro voids and gas pockets between dielectric layers increasing the dielectric losses because of localized ionization. Incomplete oil penetration also reduces the heat dissipation capability causing temperature rise and elevated losses. Minor inconsistency in the production line can cause significant increase in the tan δ values causing accelerated insulation aging and early capacitor degradation.

Internal electric field stress

Internal electric field stress is a major contributor to dielectric loss in capacitor bank. Overvoltage condition, frequent switching operation and harmonic resonance amplify the electric stress in the dielectric layers. High field intensity increases the dielectric polarization losses and promotes localised heating. Uneven distribution of the field is also caused by geometric imperfection and aging causes concentration of stress in the weak points. Under this sustained stress, the partial discharge inception voltage is lowered interlinking the dielectric loss to long term insulation degradation.

Moisture ingress and contamination

Moisture ingress increases the dielectric loss in capacitor bank by raising the conductivity of the dielectric film and impregnating oil. Molecules of water facilitates the ionic conduction and reduce dielectric strength leading to higher leakage current and tan δ. Contaminants like oxygen, acids or metallic particles introduced through sealing failure degrades the insulation quality. Moisture accelerates the oil oxidation and polymer degradation increasing the dielectric heating under normal operation, causing measurable increase in dielectric loss.

Effects of voltage frequency and harmonics

Dielectric loss in capacitor bank is influenced by voltage magnitude, operating frequency and harmonic content, all affects the internal electric stress and thermal performance.

The voltage increase raises the electric field intensity across the dielectric. Since the dielectric loss is proportional to the square of the voltage, even little overvoltage condition can significantly increase dielectric heating. Sustained overvoltage accelerates the insulation aging and reduces the capacitor life.

Frequency also affects the tan δ as dielectric loss increases with the frequency because the dielectric molecules must reorient more rapidly as the electric field alternates. At higher frequency, polarization fails to follow the field causing high energy dissipation per cycle. This makes the capacitors particularly sensitive to harmonic frequencies above fundamental.

Harmonic voltages introduce multiple high frequency components superimposed on the fundamental voltage. Each harmonic contributes additional dielectric loss and heating, often exceeding the fundamental design assumption based on 50/60 Hz operation.

High order harmonic is especially damaging because of frequency dependent loss characteristics like increase in ripple current stress, which can trigger localised partial discharge activity. Resonance condition between the capacitor bank and system inductance can amplify the harmonic voltage which can dramatically increase the dielectric stress and heating.

Impact on efficiency and O&M

Dielectric loss in capacitor bank directly impacts the efficiency and O&M performance by creating continuous real power losses while delivering reactive power. This loss appears as constant kvar related heat dissipation which reduces the system efficiency and increases the substation auxiliary power consumption.

Higher dielectric heating raises the internal temperature which often requires enhanced cooling, wider spacing or derating to maintain safe operating limits. With time, higher dielectric losses result in higher operating temperatures, which accelerates the aging of insulation and cause oil degradation.

From O&M perspective, the increased dielectric loss elevates the risk of premature failure such as bulging units, fuse operation or dielectric break down. This invites more frequent inspection, tan δ monitoring and even capacitor replacement, impacting the life cycle cost.

Design and mitigation process

Effective design and mitigation practices are essential to control dielectric loss in capacitor banks and ensure long term reliability. Selection of low loss dielectric materials such as high-grade metallized polypropylene with proven impregnation system minimizes the inherent tan δ from the very outset.

With proper voltage derating, the electric field stress can be reduced which will limit the dielectric heating under normal operation and transient overvoltage condition. A harmonic assessment prior to capacitor installation is critical to identify resonance risks and thus determine the need of detuned or filtered banks. Adequate cooling, unit spacing and ventilation prevents thermal accumulation. Periodic monitoring of the temperature, current and tan δ enables early detection of insulation degradation so that preventive maintenance can be undertaken.

This article is a part of the Energy storage and reactive power compensation page, where other articles related to the topic are discussed in details.