Battery management system is a specialized electronic control system, which supervises the operation of rechargeable batteries by monitoring, protecting balancing and thus optimizing the performance and safety of the battery system. The battery management system acts as the brain offering intelligence to the lead acid battery or lithium ion battery bank. It measures the current, voltage, temperature, state of charge and state of health of the batteries and using this information, the battery management system controls the charging and discharging of the battery bank within safe limits.

Modern batteries with complex chemistries often has risks of hazard or performance degradation under unsafe operating conditions like overcharging, deep discharge, excessive heat, cell imbalance. The battery management system ensures that the battery bank operates within the designed electrical and thermal limits by the proactive control strategies based on acquired data from the sensors.

Table of Contents

Main components and working of the Battery management system

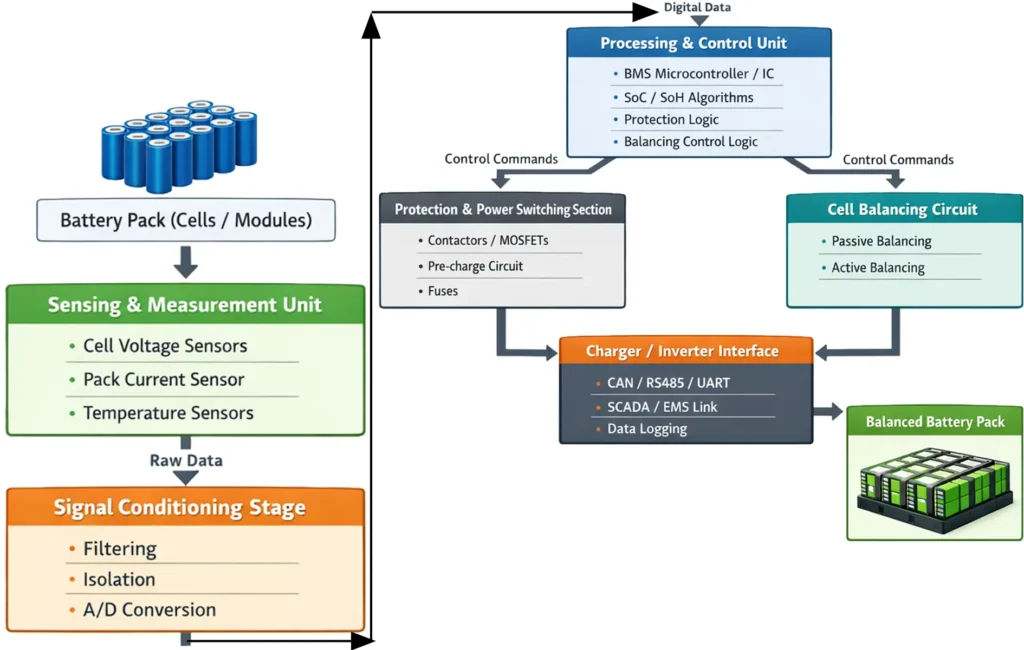

In substation using large battery energy storage systems, the battery management system is a critical subsystem which ensures safe operation, longevity, performance optimization and system integration. A typical battery management system comprises of the following components.

Sensors and measuring

These are the data gathering hardware that provides the battery management system with real-time measurements required for monitoring and proactive decisions. Among them are,

Cell voltage sensors: The voltage of cells are not measured by a separate sensor but is directly measured from the cell’s terminals. Every cell in the battery string has two sense wire, which runs to the battery management system’s measurement board, where the wires goes through a resistor divider network, which scales down the voltage. The signal then passes through analog multiplexer, which sequentially selects one cell voltage and forwards it to the measurement circuit. The selected voltage is fed into the analog to digital converter for the microprocessor to read the digital value.

Peak current sensor: The current sensor is placed in series with the main battery cable mostly on the negative side of the battery bank. The current is measured via shunt resistor method, where a low resistance shunt is placed in the current path. When current flows, a small voltage drop occurs across the shunt, and the battery measurement system computes the current using the ohm’s law. High accuracy differential amplifiers are used to sense the micro volt level signals.

The current can also be measured a hall effect sensor which is usually clamped around the main conductor. The magnetic field produced by the flowing current is measured and converted into proportional electrical signal, which is converted to digital values by ADC and then the battery management system reads it. The hall effect sensor provides full galvanic isolation and is ideal for high current systems.

Temperature sensors: The battery management system uses various temperature sensors most commonly NTC thermistors, which are resistors with a negative temperature co-efficient, RTD (Resistance Temperature Detector) used for high precision systems and semiconductor temperature sensors. These sensors are placed in the cell modules and battery terminals. The signals from these sensors passes through signal conditioning circuits and then is fed to the ADC for conversion into digital values. A microcontroller then applies calibration curve and compensation algorithm to compute the actual cell temperature. Which is then used for charge current control, thermal protection, cooling system management, etc.

Pressure sensor: These are installed inside the cell module or in the vent channel which detects the internal pressure rise and specific gases from electrolytic breakdown. The pressure sensor is typically used in advanced Battery management systems.

Battery controller

This is the core of the battery management system. It continuously processes the sensor’s data and thus acquires a real time picture of the battery status. The controller then computes the state of charge of the batteries from current integration and voltage correlation, state of health of the battery based on capacity fade and internal resistance trend, state of power from the temperature, voltage and current limits. The soc, soh and sop are computed continuously.

Some logics

| If cell voltage > max limit | Stop charging |

| If current > limit | Open contractor |

| If temperature > limit | Reduce power and actuate cooling system |

| If cell imbalance is detected | Start balancing |

Based on the decision, the controller sends commands to

- Contractor or relay to connect or disconnect battery,

- Charger or inverter to limit current or voltage

- Balancing circuit to bleed or redistribute the charge.

Protection circuitry

The protection circuitry of the battery management system is the layer of hardware which physically safeguards the battery under abnormal conditions. The protection circuitry works alongside the battery controller to prevent electrical, thermal and safety failures.

Each cell’s voltage, current and temperature is continuously monitored by the battery management system and if any parameter exceeds the safe designed limits, the battery controller commands the protection circuit to act. Over voltage or under voltage disconnects or limits the charger or the load. Over current or short circuit protection uses faster hardware comparators and current sensor to trip the main contractor within milliseconds. Over temperature protection reduces the current, activates the cooling or isolates the battery to prevent thermal runaway.

Balancing circuitry

The balancing circuitry of the battery management system ensures all cells of the battery bank maintains equal voltage during operation. Since cells age and charges at different rates, imbalance reduces the cell capacity, efficiency and safety. By continuous monitoring of individual cell voltage, cell balancing is activated by the battery controller when the cell voltage difference exceeds the preset limits.

Most battery management systems use passive cell balancing, where the excess charge from higher voltage cells is dissipated via resistors. However, the advanced battery management system uses active cell balancing where the charge form higher voltage cells are transferred to lower voltage cells via inductive or capacitive circuits. Proper cell balancing improves the battery bank’s useable capacity and extends battery life.

Communication interface

The battery management system essentially includes a communication module which enables real time data exchange to external systems like substation SCADA, energy management system, etc. Through this interface the battery management system reports the battery status and other parameters, faults and alarms. The common protocols include CAN, RS-485 and ethernet.

Common faults in battery management system

Battery management system are software based electro-electronic system which manages, protects and monitors rechargeable battery banks. Despite its robust design, faults can still occur because of hardware issues or logic issues or communication errors.

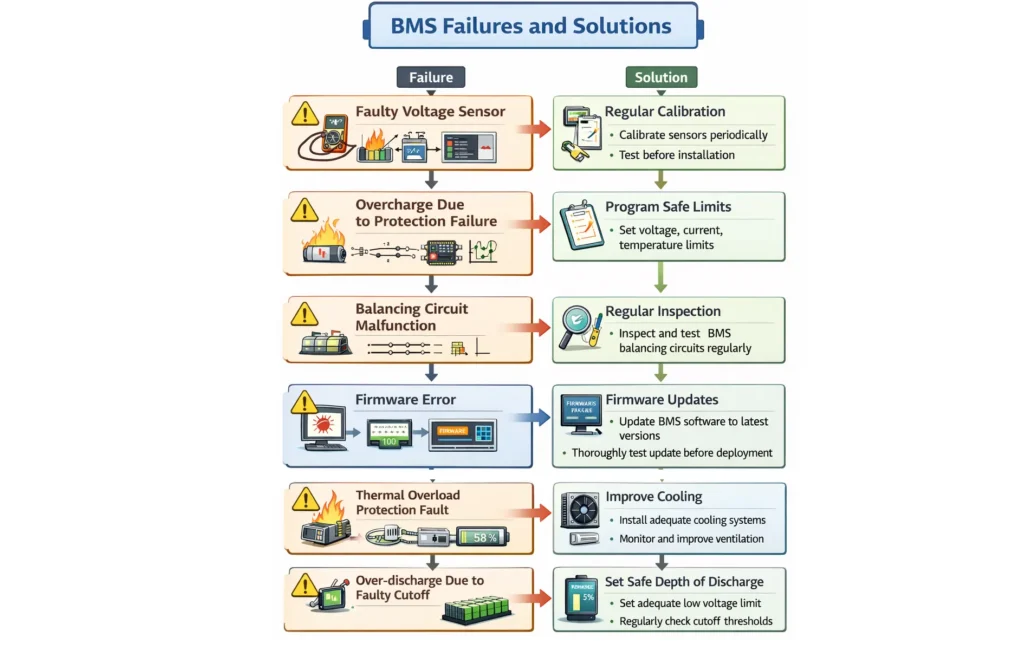

Sensor failure: Voltage, current, temperature detection is critical for monitoring and safe functioning of the system. Faulty voltage detection can lead to overcharging or deep discharge of the cells. Temperature sensor failure degrades the ability of the system to manage thermal condition and can result in catastrophic failure of the battery. The failure in the current sensor limits the system’s ability to accurately estimate the state of charge (soc) and state of health (soh) of the battery.

Communication failure: The system’s controller communicates with contractors, charger and relays over communication modules such as CAN or ethernet. Any interruption or instability in the communication module can cause the system loose control over the connected devices. Typical causes includes wiring issue, loose connector or electromagnetic interference.

Firmware error: The system controls the estimation, protection, logic and balancing during charging and provides discharging rates and sometimes limits the discharge to prevent deep discharge. Bugs or firmware issue can cause the system to miscalculate the state of charge leading to incorrect charging or discharging action. Firmware issue can also cause misinterpretation of the sensor data and cause unwarranted cut-offs.

Balancing system failure: Cell balancing circuits match all cells charge states. Faults in the balancing circuitry (active or passive) can cause imbalance in the cells causing some cells to overcharge or discharge earlier compared to other cells. Faults in the passive circuits can cause excessive heating in the balancing resistors.

This article is a part of the Energy storage and reactive power compensation page, where other articles related to the topic are discussed in details.

References: