A trivector meter is a three phase energy meter that measures the three vectors of power namely active (KW), reactive (KVAR) and apparent (KVA) and integrates over the time to compute the active, reactive and apparent energy. Trivector meter also measures the power factor and maximum demand integrated in a single unit. It is essential in commercial and industrial metering because large 3 phase load draws both real and reactive power and hence must be billed for the overall energy consumption.

Trivector meters are widely used in places requiring precise metering of multiple electrical parameters such as in substations, HT consumer metering panel, DG synchronization panel, etc.

Table of Contents

Why do we need a trivector meter?

A trivector meter is required because 3 phase industrial load draws multiple components of power KW, KVAR, KVA. A normal energy meter only records KWh which is not enough for industrial billing as it requires deeper insights of the system like real energy consumed KWh, reactive energy consumed KVARh, apparent energy in KVAh, maximum demand in KVA or KW and power factor.

Industrial load like motors, welding machine, compressor, pumps, HVAC systems, etc all consumes reactive power to create the required magnetic field in addition to the active power. When the reactive power in the system becomes more, the power factor drops and because of which current in the system increases. This high current causes heating in the cable, transformer and other utility’s equipment. The low power factor increases the technical losses, lowers the system efficiency and causes voltage drop in the system.

It forces the utility to invest more in uprating the conductors and the transformers and cooling systems, if the reactive power or apparent power is not billed.

KVA = √(KW2 + KVAR2) , shows that even if the active power is low, high reactive power can consume the entire KVA capacity, limiting the loading capacity of the utility’s transformer or feeder.

Hence, billing for KVA/KVAR ensures fair usage of transformer capacity and it makes the trivector meter very important as it can measures all the three components.

How does the trivector meter works?

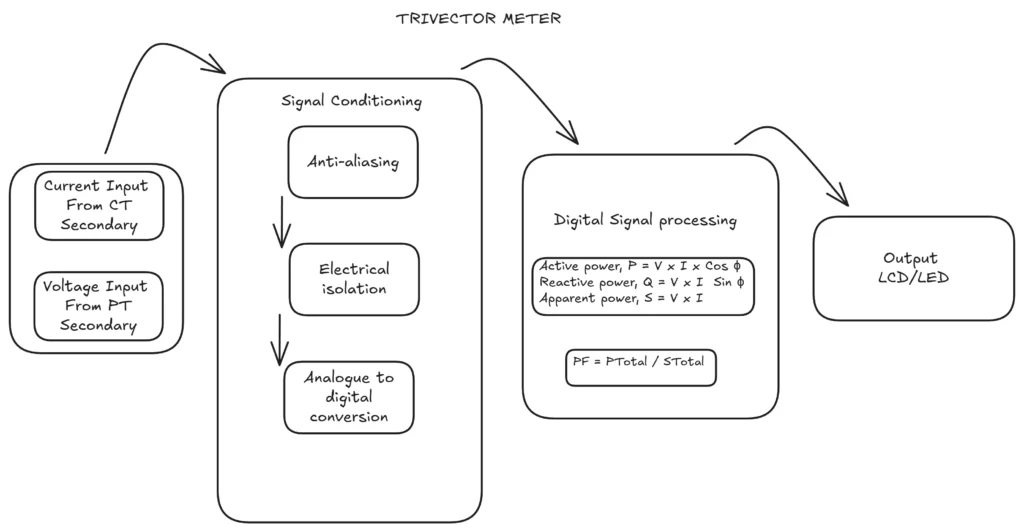

The meter measures all the component of the power by utilizing precise digital sampling and DSP algorithms. The working of the which can be broken into the following stages:

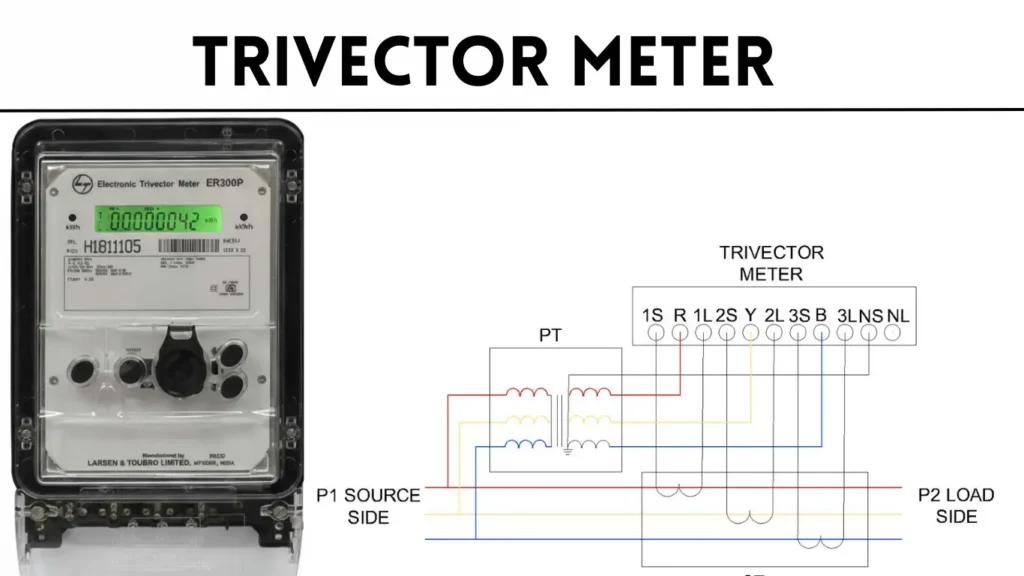

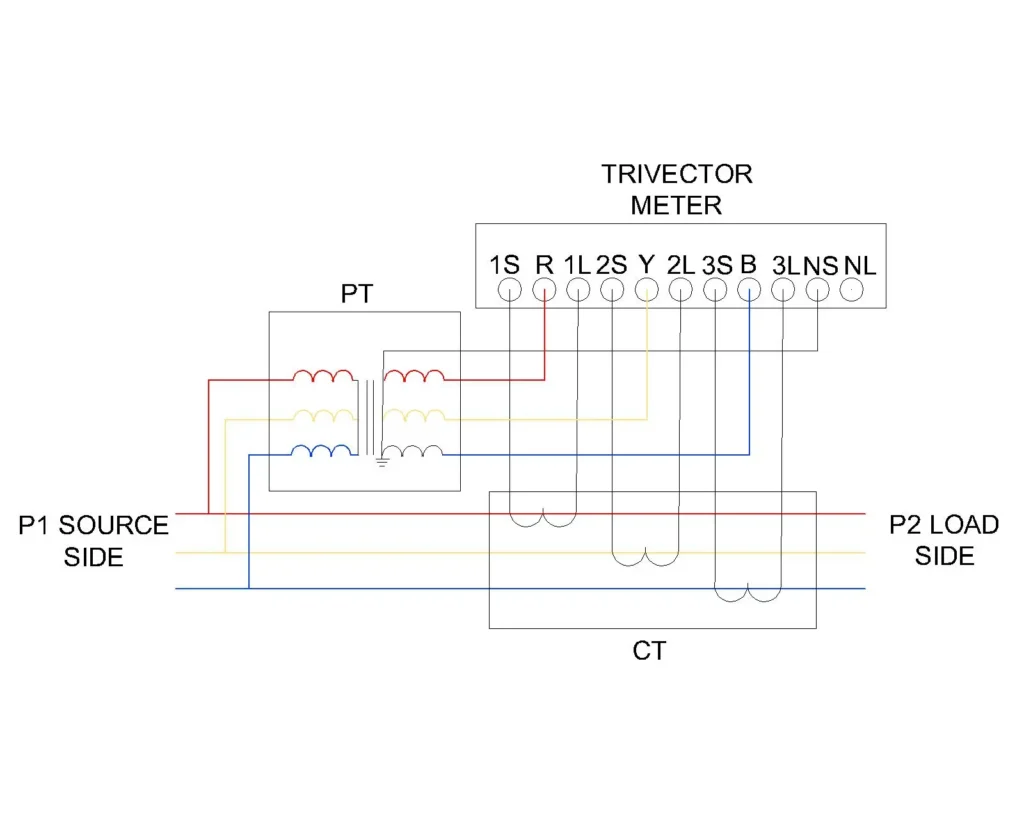

Input sensing: The meter receives the current and voltage input in its terminal via the current transformer and voltage transformers, scaling down the current and voltage proportionally to the mains up to measurable limit. For billing the accuracy class of these meters are 0.5s class for HT consumers and 0.2 or 0.2s for substation or generation metering purposes.

Signal conditioning: After receiving the inputs from CT and PT, the current and voltage signal are conditioned in the signal conditioning block of the meter for precise digital measurement. This block performs three functions:

Anti aliasing filtering: Before the digitization of the input signal, the high frequency noise, switching harmonics and transients are removed via a low pass anti aliasing filter which allows only the fundamental and relevant harmonics to enter the analogue to digital converter (ADC).

Electrical isolation: In order to protect the internal circuitry of the meter from overvoltage, surges and fault currents, galvanic isolation from the CT and PT is required. In order to achieve this isolation, Opto isolator or magnetic isolator or isolation amplifiers are used. These also filters out the noise of the power system.

High speed ADC conversion: After the filtering and isolation of the input signals, it is fed into the analogue to digital convertor 16 or 24 bit. It samples the voltage and current thousands of time per second and captures the waveform shape. This helps the accurate computation of KW, KVAR, KVA, power factor, harmonics, load profile and maximum demand.

Signal conditioning is a critical process as any noise can potentially corrupt the power calculation, saturate the ADC, distort the waveform leading to billing errors.

DSP Computation: The digital signal processor is the brain of the trivector meter as it does all the calculation based on the sampled voltage and current signals from each phase.

The DSP computes the power components using the basic formula in every few milliseconds.

Active power, P = V x I x Cos ϕ

Reactive power, Q = V x I Sin ϕ

Apparent power, S = V x I

For three phase system, it computes Active power, PTotal = PR+PY+PB , Reactive power, QTotal = QR+QY+QB and apparent power STotal = √(PTotla2 + QTotal2)

Once the instantaneous power is computed, the energies, active, reactive, and apparent are computed by the integration over the time.

DSP also computes the power factor as PF = PTotal / STotal

These calculation runs continuously, enabling the meter to track lagging or leading power and generate the real time load profile.

Display and communication: Modern meters are equipped with a LCD or LED display for onsite reading of KWh, KVARh, KVAh, PF, Maximum demand, Frequency, Voltage and Current. Communication interfaces are also included such as RS-485 and optical port for local data download. The meter can also be integrated with AMR systems for remote meter reading and load profiling.

Installation requirements

The meter must be connected to the secondary of CT and PT.

Ensure the polarity of connection and phase sequence to avoid PF and energy reading errors. If in the field P1 is towards the source and P2 is towards load then

| CT Secondary | 1S1 | 1S2 | 2S1 | 2S2 | 3S1 | 3S2 |

| Trivector meter | 1S | 1L | 2S | 2L | 3S | 3L |

Note: In 1S1 the first digit 1 indicates R phase and can change to 2 and 3 indicating Y and B phase. S indicates the secondary of CT and last digit indicates polarity 1 for source and 2 for load.

A reliable neutral is required for the meter’s auxiliary power supply which is used to power the DSP, memory, communication module and measurement circuits. A floated neutral can cause the meter to reboot.

Although, static meters have very low burden compared to the rated limits of CT and PT. However, long cables, terminals and links can add to the burden. Hence, it is to be strictly taken care of.

Ensure bonding of the meter’s body and the RS-485 communication shield to prevent noise pickups and communication errors.

This article is a part of the Metering page, where other articles related to the topic are discussed in details.