A power quality meter is a special type, high speed digital device that is used for precise measurement and record of electrical disturbances and waveform abnormalities in the electrical system.

Power quality meters capture and analyses the transient events, voltage sag or voltage swell, unbalance and harmonics in the system unlike the usual energy meters. It is installed in the LT/HT panels, capacitor banks, DG sets, UPS and renewable energy interfaces.

Table of Contents

Why is the power quality meter used by utilities and industries?

Utilities and industries uses the power quality meters for three critical reasons:

Asset protection: When the power quality is poor, like voltage sags, swell, presence of harmonics and transients, the sensitive equipment, motors, variable frequency drive and control systems are prone to damage. The power quality meter continuously monitors and records these events, which allows the users to identify the source of the disturbance and then implement corrective measures like filters and surge suppressors, thus saving the costly equipment from breakdown.

Efficiency optimization: Power quality meter monitors parameters such as power factor, total harmonic distortion (THD). Utilities require these data to identify those consumers who are non-compliant and avoid system losses on their feeder. Industry uses these data to improve the energy efficiency, correct power factor and avoid penalties.

Compliance and dispute resolution: Power quality meter ensures compliance to international standards like IEC 61000-4-30 and IEEE 519. As the power quality meter captures high resolution data with wave form, hence it provides an undeniable record necessary for verifying the supply quality and contractual dispute resolving.

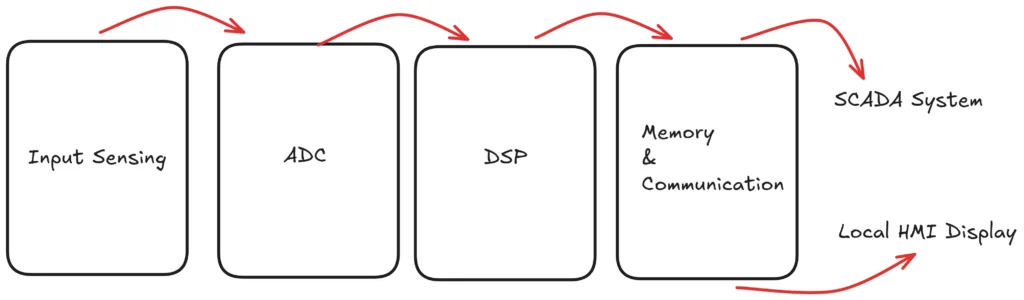

Power quality meter’s architecture

Input sensing: The current transformer and the voltage transformers transform the high current and high voltage high to a measurable value. The input from the CT and PT secondary is then conditioned by the electronic circuitry like filtering and isolation to supress the noise and protect the down stream components of the meter.

Analogue to Digital conversion ADC: Power quality meter utilizes high resolution 24 bit ADCs in this stage to operate at a very high sampling rate at 512 samples per cycle or even greater to capture the power frequency and events like transient which are high speed and short-durational. Time stamping of the digital samples are done to provide precise reference for event analysis and logging by synchronization with GPS or NTP.

Digital signal processing: The digital signal processor or DSP is considered as the brain of the power quality meter as it executes the complex mathematical algorithms like fast Fourier transformation which breaks down the complex waveforms into fundamental and harmonic components. The DSP of the power quality meter computes all standard power quality parameters like the RMS voltage, current from the sampled data of ADC, the harmonics up to 63rd or 127th order and the total harmonic distortion. The DSP transforms the 3 phase voltages and current into positive, negative and zero sequence, which is used to detect the unbalance. Apart from these the DSP also computes the active, reactive and apparent power.

The DSP of the power quality meter continuously compares the measured parameters to internal threshold and on detection of anomaly, it saves a waveform snapshot typically 5-10 cycles before and after the event and stores the oscillography files for further analysis.

Memory and communication: This is the final stage of the power quality meter where the processed information is stored, displayed and ready for transfer. The power quality meter has a large and non-volatile memory to store all the time stamped data, event logs and captured waveforms. The meter also has a human machine interface with a display which is used to access real-time readings, waveform plots and phasor diagrams.

For communication purposes, the power quality meter uses the RS-485, ethernet, fibre optic or cellular interface to transmit data to the centralized utility system such as SCADA.

Power Quality meter metrics

The key power quality metrics are

Total Harmonic Distortion Voltage (THD-V): It is the ratio of the RMS value of all harmonic voltage component (2nd/3rd/….) to the RMS value of the fundamental voltage. A high THD-V value affects all the connected loads as the voltage waveform distorts.

Total Harmonic Distortion Current (THD-I): It is the ratio of the RMS value of all harmonic current component (2nd/3rd/….) to the RMS value of the fundamental current. High Values of THD-I is often caused by nonlinear loads which contributes to excess heating and power losses in the power system.

Displacement power factor, DPF: DPF is the cosine of the phase angle between the fundamental voltage and fundamental current. It ignores all the harmonics. DPF = cos ϕ It tells how much the voltage wave form has shifted from the current wave form. DPF can be improved by adding capacitor banks.

True Power Factor, TPF: It is basically the ratio between the real power KW to the apparent power KVA, considering all harmonics. It includes both the phase shift and waveform distortion.

TPF = P / (Vrms x Irms) or, TPF = DPF x Factor of distortion.

Factor of distortion = 1/ √ (1+THD-I2)

TPF is always less than or equal to DPF and can only be corrected by using harmonic filters.

Voltage sag: It is the momentary dip in the rms voltage which can be typically between 10 % to 90 % of the nominal voltage value lasting from 0.5 cycle to 1 minute. It is often caused by system faults or because of inrush during starting of large motors or during switching of large loads.

Voltage swell: It is the rise of the rms value of the voltage for a short period of time ranging from 1.1 to 1.8 times the nominal voltage lasting anywhere between 0.5 cycle to 1 minute. It happens because of sudden loss of load or single line to ground faults.

Under or overvoltage: It is basically the sustained deviation of the rms voltage below or over the nominal voltage for a duration usually longer than 1 minute.

Interruption: It is the complete loss of voltage below 10% of the nominal value for a specified duration.

Transients: These are the non power frequency disturbances which lasts for a short duration and usually have high magnitude. The transients are classified as impulsive unidirectional spike resulting from the lightnings or oscillatory which are rapidly decaying sine wave resulting from switching. Power quality meters have a very high sampling rate and can easily capture these events accurately.

Short term flicker: It is the measure of fluctuation of voltage which causes light flickering evaluated over a interval of 10 minutes. It is caused by variable or cyclic drawl of current such as in arc furnaces, welding machine, etc. It tells how annoying the flicker is for 10 minutes. The short-term flicker limit is usually 1.

Long term flicker: It is usually a 2-hour index which indicates the severity and persistent voltage fluctuation over time. It is calculated as a cube root of 12 consecutive short term flicker. It tells if the flicker persists over time. The limiting value for long term flicker is usually 0.8.

Frequency drift: It is the measure of deviation of the frequency from the fundamental value 50 Hz or 60 Hz. Although for major grid, it remains stable but frequency drift is important for isolated and distributed generations.

Voltage unbalance: It is basically the ratio of maximum deviation from the phase voltage to the average phase voltage. Voltage unbalance of 2 – 3% can severely heat up the loads like motors.

Current unbalance: It is the degree to which the three-phase current differ from each other. It is caused by uneven single phase loading on a three-phase system.

This article is a part of the Metering page, where other articles related to the topic are discussed in details.