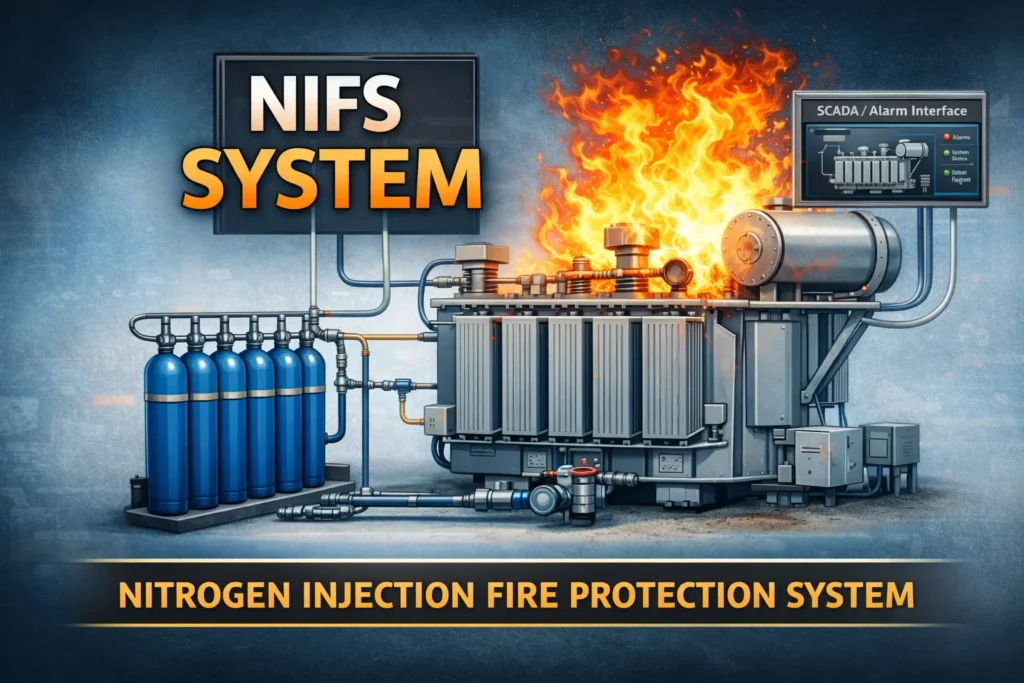

The Nitrogen Injection Fire Protection System, NIFPS is a dedicated safety system for oil filled power transformers, which is capable of preventing catastrophic fire and explosion during severe internal electrical faults. The NIFPS system operates rapidly by draining the hot oil, isolating the conservator tank, and injecting high pressure nitrogen gas into the main tank of the transformer, thus creating a non-combustible, inert environment inside the transformer main tank and preventing any fire hazard.

Power transformers have large volume of flammable insulating or transformer oil which poses a major fire risk escalated by major uncontrolled fault. NIFPS provides the active fire prevention measure for the substations.

Table of Contents

Risk of fire in oil filled transformer

The oil filled power transformers inherently carries the risk of high fire and explosion because of high volume of insulating oil and high energy density in the internal circuits of the transformer. Under normal operating conditions, the transformer oil provides the electrical insulation and acts as a medium of heat dissipation. However, during faults the same oil becomes a major risk factor for a fire hazard.

Internal faults such as winding insulation breakdown, inter-turn short circuit or the core insulation failure can initiate formation of electrical arc inside the tank of the transformer. The arc instantly produces extreme heat causing rapid localised temperature rise exceeding thousands of °C as per IEEE 1584, which decomposes the transformer oil into combustible gases like hydrogen, methane and acetylene. This sudden change in pressure inside the transformer tank can overwhelm the mechanical strength of the tank causing a rupture. These released gases and hot oil coming in direct contact with atmospheric oxygen can ignite leading to a catastrophic fire and explosion.

External hazard such as bushing flashover can ignite the oil vapours in the surrounding. Oil leakage from gasket or flange can get exposed to hot surfaces leading to sustained fire. Failure of cooling system can increase the operating temperature, accelerating the aging of insulation and probability of fault.

Because of these combined faults, oil filled transformers are regarded as the highest fire risk asset in any substation which requires special protections like Buchholz relay, pressure relief valve, Fire wall and systems like NIFPS.

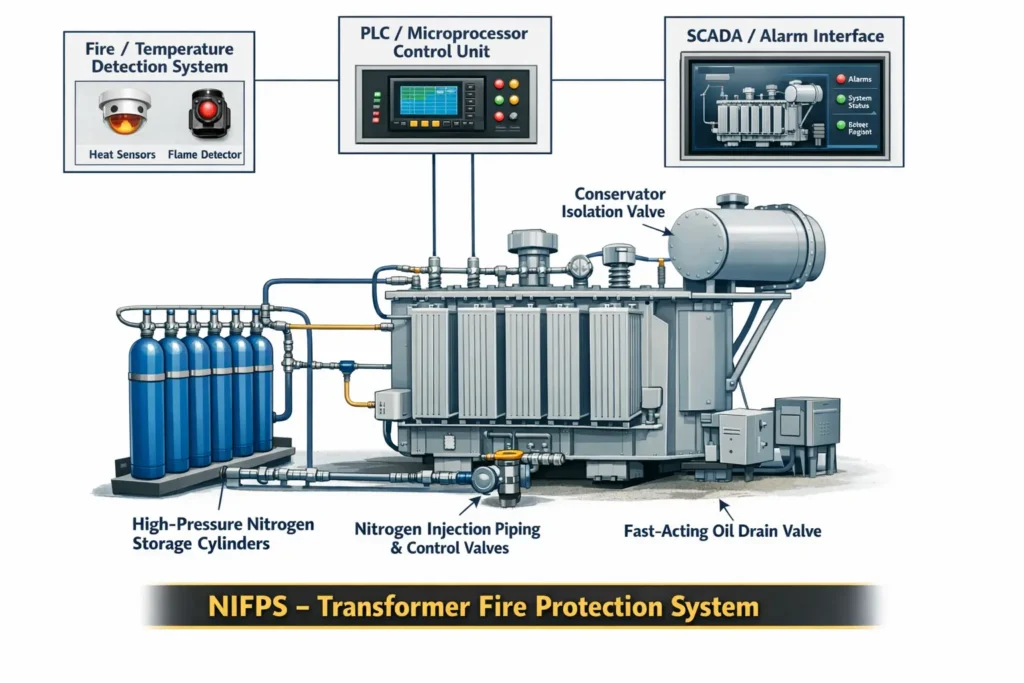

Major components of NIFPS

Temperature sensors

The NIFPS uses heat sensors which are basically linear heat detectors or manual temperature probes which are capable to sense the abnormal temperature rise inside the top of the main tank of the transformer and generate activation signal for the fire protection system. These detectors are calibrated below the flash point of the transformer oil to prevent the explosion and tank rapture.

Control unit

The control unit of the NIFPS is either microprocessor or PLC based, which receives the signal from the temperature sensors and protection relays and intelligently activates the oil drain valves, initiates nitrogen injection by actuation of the valves and also controls the conservator isolation valve. The control unit also interfaces with the substation SCADA for alarm visualization, system monitoring, status updates, and historical logs. SCADA integration improves the situational awareness of the substation technician and operator and helps to verify activation and system health.

Fast acting oil drain valve

The fast-acting oil drain valve is a quick opening mechanical valve which operates to drain the pre-determined volume of the top oil in the transformer tank and reduce the internal pressure. They are sized at 80mm dia approximately. Technical specification mandates fast oil drainage within seconds to avoid internal pressure buildup. The piping is designed with minimal bends for allowing prompt flow of oil.

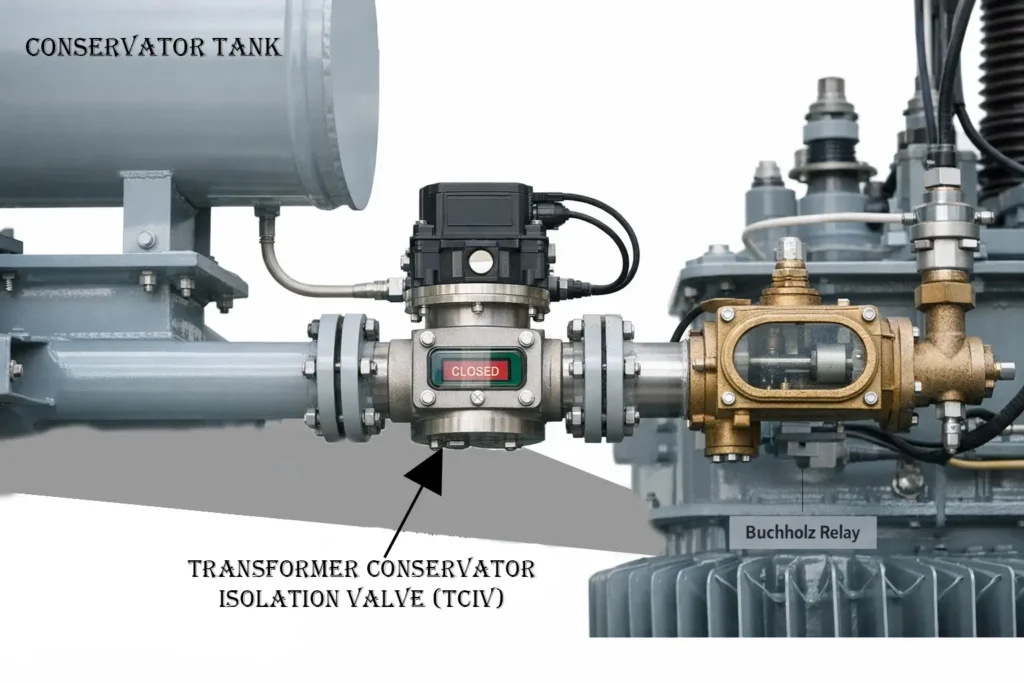

Conservator isolation valve

The transformer conservator isolation valve (TCIV) is flow sensitive valve with remote indication, installed between the conservator and Buchholz relay. It does not isolate the conservator during the normal breathing of the transformer oil but automatically shuts off during abnormal flow of oil as speed of oil increases typically beyond 1.5 m/s. The valve usually has a proximity switch for alarm and visual indication and has a pad lockable function to avoid unintended operation.

High-pressure Nitrogen storage cylinder

Nitrogen cylinders are specified to provide high pressure inert gas for injection into the transformer tank. Typical design feature includes capacities around 10 m3 at 150 kg/cm2 for transformers up to 60000 L of oil. While larger systems will require larger capacity. The cylinders are fitted with pressure indication devices to monitor the cylinder pressure. The NIFPS systems are required to complete the nitrogen injection into the transformer tank within 30 seconds of activation to achieve the fire suppression objective.

Nitrogen injection pipe and control valve

The injection piping is specified with suitable flanged connection and control valve which are sized effectively for high pressure delivery from the storage cylinder to the bottom of the transformer tank. The valves are engineered for ensuring high injection rate 15-25 m3/min for transformers below 100 MVA, which corresponds to transformer volume and fire suppression requirement. The pipes are made of galvanized or heavy-duty steel basically corrosion resistant to withstand environmental and thermal stress.

Working principle of NIFPS

The NIFPS system operates on a coordinated Drain and stir principle, which combines rapid pressure relief with inert gas agitation to suppress internal fire condition before a catastrophic failure.

Detection and activation

The NIFPS system remains in continuous monitoring mode, receiving input from the protection and monitoring devices of the transformer including differential protection relay, Buchholz relay, pressure relief valve, OTI and WTI sensors and dedicated fire sensors.

When any of these devices detect abnormal condition such as rapid gas generation, excessive temperature rise, sudden internal pressure rise or arcing related disturbances, the control system classifies it as an event of risk and immediately activates the NIFPS operating sequence. The initiation can occur automatically or via supervisory control depending upon the configuration.

Oil drain and Pressure reduction

Upon activation, the fast-acting valve opens within seconds and discharges the pre-determined volume of hot oil from the top of the main tank to the oil pit. It reduces the internal tank’s pressure, removes the upper layer of oil which is the hottest region close to ignition temperature and relives the mechanical stress built-up on the tank walls and structural components. Rapid depressurisation saves the main tank from explosion at this stage.

Conservator isolation

Simultaneously, the TCIV closes and disconnects the conservator from the main tank. This prevents additional oil flow in the main tank during the emergency. By isolation of the conservator tank, the system prevents re-pressurisation of the main tank while nitrogen injection is in process.

High pressure nitrogen injection

Immediately after the oil drainage, the high-pressure nitrogen is injected into the transformer tank from the bottom control valve. The nitrogen gas rises through the remaining volume of the transformer oil producing a powerful mixing and agitation effect. It displaces the oxygen at the oil surface, forming a blanket of inert nitrogen which prevents any oxidation. The nitrogen stirs and cools the remaining oil volume reducing the temperature below the flash point

The oxygen fuel heat triangle required for combustion is busted by the nitrogen as it is inert and non-reactive, thus suppressing the combustion without degrading the transformer’s insulation and oil quality.

Conclusion

With the removal of oxygen, reliving of internal pressure, reduced oil temperature, combustion becomes unsustainable and the risk of tank rupture reduces. At this stage the probability of re-ignition becomes extremely low.

Thus, NIFPS prevents the transformer from exploding and extinguishes the developing internal fire at early stage protecting both transformers, surrounding equipment and substation infrastructure.

This article is a part of the Transformer page, where other articles related to the topic are discussed in details.