The magnetic core of the transformer is the fundamental working element which is responsible for provision of low reluctance path for the magnetic flux, enabling efficient energy transfer between the primary and the secondary windings of the transformer. The magnetic core design of the transformer directly influences the transformer efficiency, no load losses, thermal performance, noise, size and reliability. A poor design of the magnetic core causes the magnetizing current to increase, with excess heating, high operating losses and lowers transformer’s life. With careful engineering, economic, stable, and durable transformer can be achieved.

Table of Contents

Core materials

Silicon Steel

Cold rolled grain oriented silicon steel is the predominant material for the transformers because it minimizes the core losses while ensuring high magnetic flux densities up to 1.9T. This makes sure that the transformer remains compact and efficient.

CRGO steel is manufactured with crystal grains aligned in the rolling direction, which enhances the movement of magnetic flux in this direction. This results in better permeability in the flux path and reduces the magnetizing current. With the aligned grains and optimized structure of the CRGO steel, the magnetic domain can flip with minimum resistance and less energy dissipation.

The core steel is produced in very thin laminations under 0.30mm and are insulated which reduces the circulating current. The silicon content (<3.5%) also increases the resistivity further reducing the eddy current.

Amorphous Alloy

The Amorphous alloy are used as magnetic core because it has a non-crystalline atomic structure which drastically reduces the energy expense during magnetic domain flipping, resulting in low hysteresis loss.

Typical amorphous alloy core loss is 0.2-0.3 W/kg at 1.4T, and 50 Hz frequency, compared to CRGO core loss, which is 0.9-1.3 W/kg at 1.5T and 50 Hz. This shows a 60-75% reduction in the no load loss compared to CRGO steel.

The amorphous alloy has a superior electrical resistivity around 130-150 µΩ·cm compared to 45-50 µΩ·cm for silicon steel. This suppresses the circulating current in the core material further reducing the core loss.

The amorphous cores are manufactured as very thin ribbon (0.025-0.035 mm) compared to CRGO laminations of 0.23 – 0.30 mm. This thin section reduces the eddy current loop area, minimizing the losses.

Because amorphous alloy has lower maximum saturation flux density, for carrying same power without saturating, amorphous alloy core requires larger cross sectional area compared to CRGO core. This leads to larger size of winding, more volume of steel and large transformer assembly and cost.

Nanocrystalline materials

Nanocrystalline materials consists of ultra fine grains at nanometre scale, which is formed by controlled annealing of the amorphous alloy. This unique structure gives this magnetic core excellent magnetic properties well above the traditional silicon steel and other magnetic core materials.

This magnetic core material exhibits extremely high magnetic permeability because of the ultra-fine grains which allows the magnetic domains to align very easily under the applied field, which allows excellent flux conduction and reduced magnetizing current. This type of magnetic core is used where precise flux control is needed, example in current transformer and other measuring instruments.

Because of the fine micro structure of this magnetic core, it exhibits a narrower B-H loop compared to other magnetic core materials. Thus the hysteresis loss is reduced during each magnetising cycle, contributing to higher efficiency.

The nanocrystalline materials also have high resistivity than traditional silicon steel, which helps in limiting the eddy current formation. This specially counts at higher frequency where eddy current loss dominates. Nanocrystalline magnetic core material supports wider frequency range extending to KHz and beyond.

Core Construction

Laminated core

The magnetic cores of the transformers are rarely made as a solid block but are made from stacked thin laminations. Each lamination sheet is coated with a layer of insulation commonly oxide film or varnish to make it electrically isolated from adjacent sheets. This design is very essential to reduce the core losses, specially emanating from the eddy current.

In alternating magnetic fields, the changing flux induces circulating currents in conductive materials. This current flows in loop and generates power loss and heating which reduces the efficiency of the transformer. Use of thin lamination instead of the solid core breaks the path of the eddy current and confines them in the thin sheet with high resistance and as a result less current flows and less energy is wasted.

The eddy current loss is greatly dependent on the thickness of the magnetic core material and follows Peddy ∝ t2, where Peddy is the eddy current loss and t is the thickness of the magnetic core. It shows that halving the thickness of the laminations reduces the eddy current loss by a factor of 4. Typical lamination thickness of CRGO steel used for 50/60 Hz system frequency is 0.23-0.35 mm.

Alternative Geometry

Distributed Gap and Wound cores

In specialized transformers distributed air gaps are introduced in the magnetic path for controlling the magnetizing current, prevent core saturation and stabilizing the inductance.

Introducing the air gap changes the effective permeability of the magnetic circuit (µeff).

µeff ≈ Lc / Lg , where Lc = effective magnetic path length in the core and Lg = total length of the air gap.

Increasing the length of the air gap, increases the reluctance and lowers the effective permeability, which makes the required flux level to saturate the core, higher. This reduces the tendency of the core to saturate under DC bias or transient condition. The application of this is common in power electronics and not in standard power transformers.

Toroidal core

Toroidal magnetic cores are closed ring shaped structure which forms continuous and closed magnetic path. It provides minimal flux leakage which improves the coupling. It improves the symmetric flux distribution which reduces the localized hotspots and lowers the magnetizing current. This geometry reduces the stray field and helps to limit the electromagnetic interference. It exhibits lower noise because of the continuous grain and absence of sharp corners.

Structure design of the magnetic core

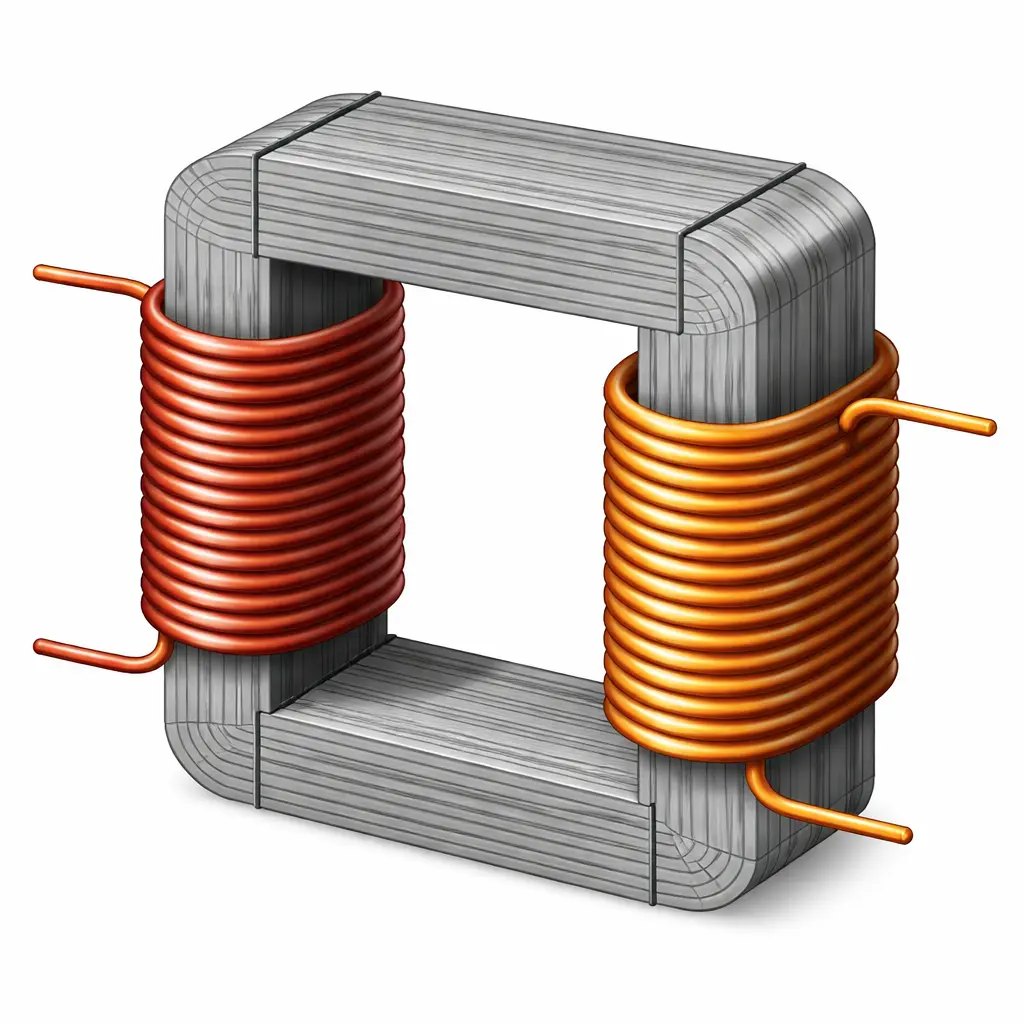

Core type construction

In this design the core forms the vertical limbs and the windings are placed around the limbs. It provides simpler winding assembly, lower core material cost and efficient magnetic path. It is widely used in distribution and power transformers.

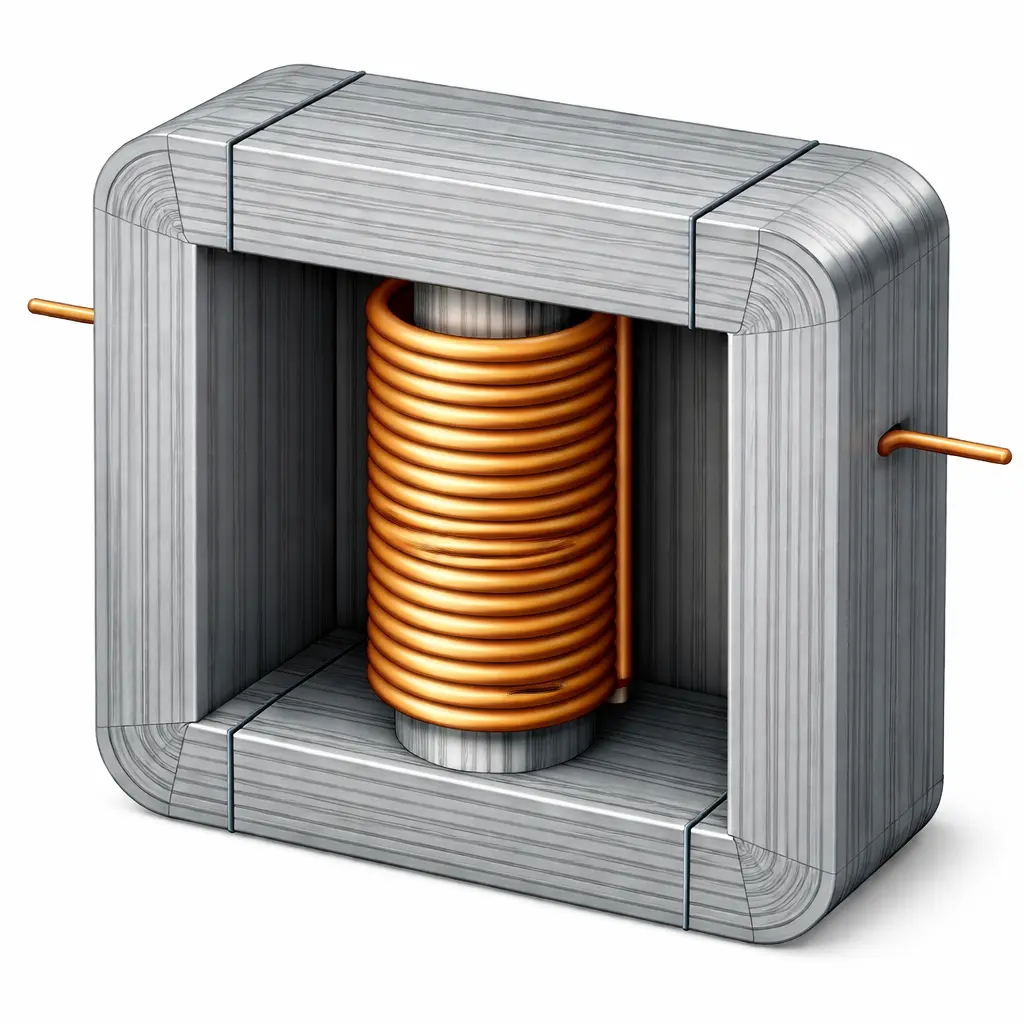

Shell type construction

In this design the core surrounds the windings of the transformer and the magnetic flux divides into multiple parallel paths. This design enhances the mechanical support for the windings and improves the short circuit withstand capability. This design reduces the leakage flux and provides better control of the magnetic field distribution in the transformer.

This article is a part of the Transformer page, where other articles related to the topic are discussed in details.