The conservator tank is an auxiliary oil reservoir to the main tank of the transformer. The conservator tank is mounted above the main tank of the transformer and is connected to it via a pipe. The primary function of the conservator tank is to accommodate expansion and contraction of the transformer oil and keep the main tank of the transformer filled during operations. The conservator tank also cuts the direct contact of the transformer oil with the atmosphere, which reduces the oxidation, moisture ingress and insulation degradation.

Table of Contents

Purpose of the conservator tank

The conservator tank performs three important functions that protects the transformers from internal stress and external contamination.

Volume and pressure management

The volume of transformer oil is very sensitive to temperature. As the transformer operates under load, the transformer oil heats up and expands because of the losses of the transformer are constantly being liberated as heat in the transformer’s core and windings. The expansion of the oil because of the heat, if is not managed, it would result in the bulging of the main tank or leakage.

The conservator tank is partially filled with oil and hence facilitates the necessary room for the oil, as it expands, preventing the rupturing of the main tank, which would otherwise occur because of excessive internal pressure.

As the oil cools down, the volume of the oil shrinks, the conservator tank sends the stored oil to the main tank via the pipe and it prevents the vacuum formation or air pockets in the main tank.

Oil level stability

As in the transformers, the core and the windings are always fully submerged under oil, the conservator tank maintains the insulation integrity by not exposing the core and the winding of the transformer to air during operations, which would otherwise result in catastrophic insulation failure.

The conservator tank of the transformer also aids in the cooling continuity as it maintains the convection currents which are responsible for effective cooling of the transformer.

Contamination protection

The conservator tank minimizes the direct contact of the oil with the atmosphere, which is the primary source of oil degradation. The conservator tank reduces the surface area of the oil exposed to air compared to an open tank. It slows down the oil oxidation process which would create sludge in the oil. The conservator tank works in tandem with the silica gel breather for filtering out the moisture from the air that the transformer inhaled during oil contraction.

Mounting accessories

The conservator tank also serves as mounting point for safety accessories like buchholz relay, which is mounted on the pipe connecting the conservator tank and the main tank of the transformer. It detects the gas bubbles and isolates the transformer before a fire hazard occurs.

The magnetic oil level gauge (MOG) is mounted on one side of the conservator tank which provides visual indication and sends electrical alarm if the oil level in the conservator tank falls dangerously low.

On the other side of the conservator tank, a prismatic oil gauge is mounted, which provides the visual reading of oil level via refraction of light, in a simpler glass window.

Construction and Design feature of conservator tank

The construction and design feature of a transformer’s conservator tank are governed by the need to manage the thermal expansion of the transformer oil, while resisting the environmental contamination.

Volumetric calculation

The main design requirement of the conservator tank is that it must be large enough to contain the expanded oil at maximum operating temperature of the transformer and provide enough reserve oil to the main tank of the transformer at minimum operating temperature such that the core and the windings remain fully submerged all the time.

The change in the volume of the transformer oil is calculated based on the temperature coefficient of expansion of the oil.

- ΔV = V total x β x ΔT,

- Where, V total is the total volume of oil in the transformer (main tank + radiator).

- β is the coefficient of thermal expansion for oil which is typically 0.0007-0.0008 per °C.

- ΔT is the difference between the maximum operating temperature and minimum operating temperature or ambient temperature.

Conservator sizing

The sizing of the conservator tank, as found from various utility practices that it should hold at least 10% of the total oil volume of the transformer (main tank + radiator). And always 30% of the conservator tank must be filled with oil. The minimum oil level must ensure that the Buchholz relay remains full of oil at lowest ambient temperature which is -25 °C for outdoor installation. And for maximum oil level, the conservator tank must not overflow at maximum operating temperature which is 100 °C.

The conservator tank is typically a horizontal cylindrical vessel which is made of high-grade mild steel (6mm tank thickness usually), coated with anti-corrosive paint.

Internal separation

To prevent the oil form reacting with the atmospheric air, modern conservator are designed in two types:

Atmoseal type

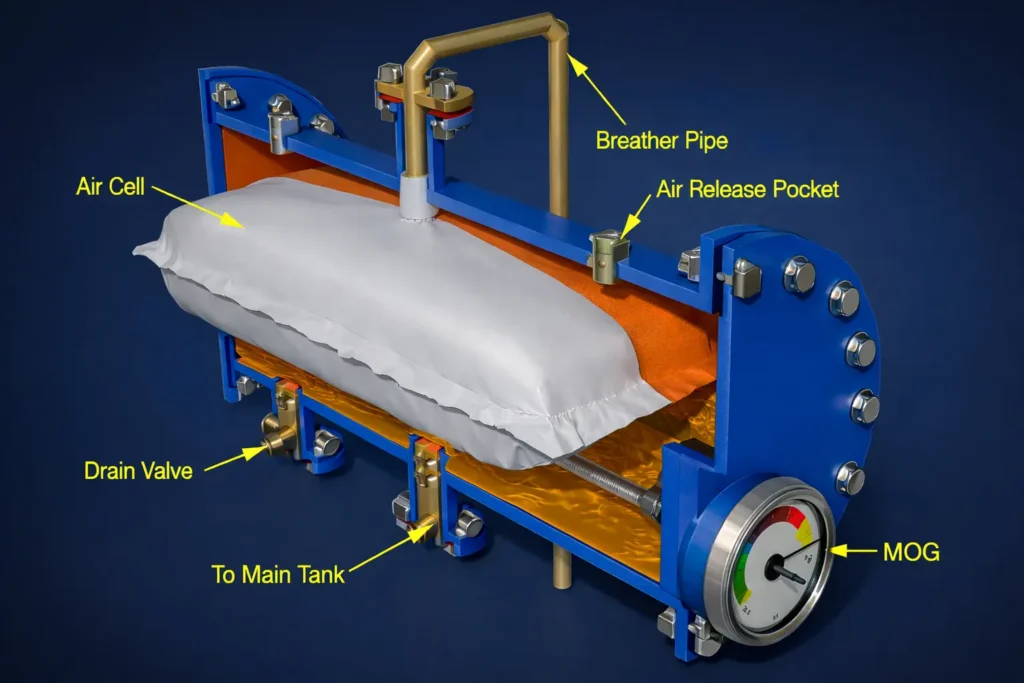

These uses Air cell which are flexible separators made of Acrylonitrile Butadiene Rubber NBR which resists oil on the outside and nylon fabric for inside strength. The air cell is vented to the atmosphere via a breather. As the oil expands inside the conservator, it pushes the air cell, deflating it and as the oil contracts, the air cell bag inflates. Thus, it ensures zero contact between the oil and the air.

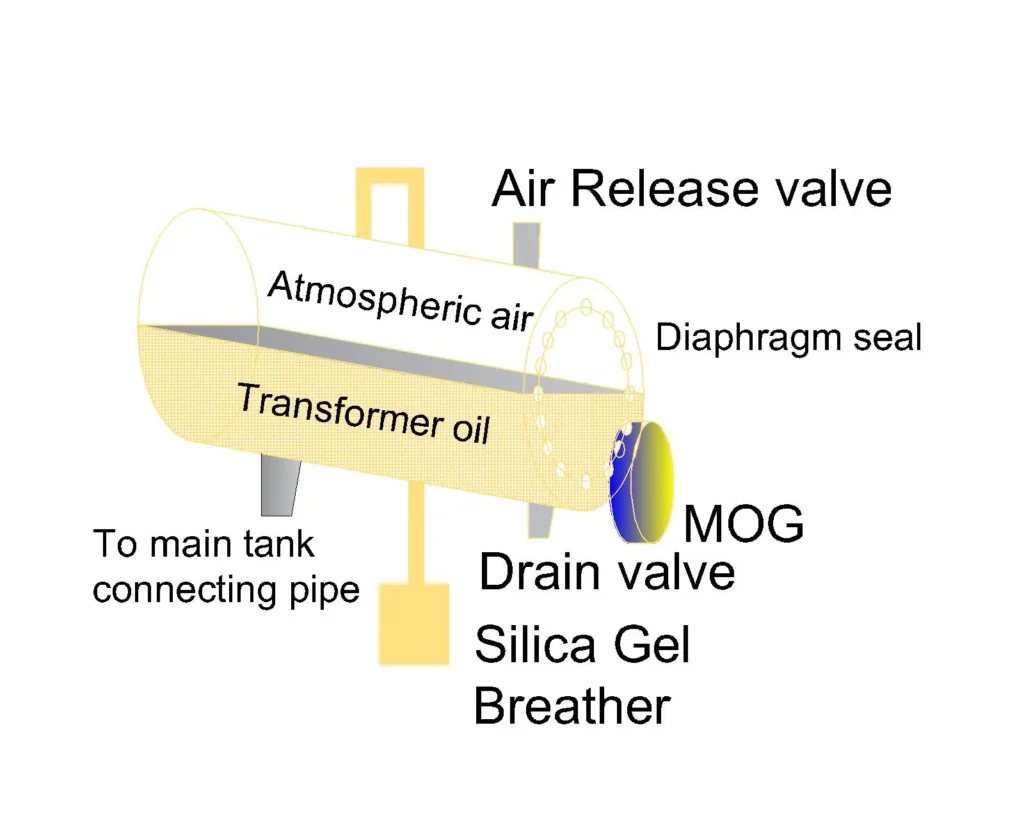

Diaphragm type

These conservator type uses a flexible membrane made of rubber which is clamped between the two hemispherical halves of the tank. The diaphragm acts as a physical barrier where the oil resides below it and the air is above the diaphragm. As the oil expands, the flexible diaphragm is pushed upwards and air at the top is pushed out of the breather. While during contraction, the diaphragm falls back and air is inhaled.

Connection piping

The connection pipe from the conservator to the main tank of the transformer is slopped at an angle of 7° to 9° with the horizon for allowing the gas bubbles, formed, to rise towards the Buchholz relay and not cling to the pipe. The pipe must extend 50-100mm inside the conservator tank in order to prevent the sludge or sedimentation at the bottom of the conservator, enter the main tank.

Conservator for large transformers are designed to withstand a full vacuum pressure of where internal pressure is zero and external pressure is 101.3 Kpa, if specified as vacuum proof.

Valves

The conservator tank is fitted with a drain valve which placed at the bottom for draining out the conservator during maintenance and inspection. It is also fitted with an air release valve at the top for venting out the trapped air during the oil filling. Some utility uses a transformer conservator isolation valve (TCIV) which is usually placed between the Buchholz relay and the conservator. It functions to trip the transformer if the oil flow exceeds the rated flow rate typically 1.5m/s, indicating a major leak.

Diaphragm vs Air cell conservator tank

| Feature | Diaphragm | Air cell |

| Construction | Flat sheet of rubber clamped across two halves of tank. | A floating balloon inside the tank. |

| Maintenance | Requires opening of the tank halves. | Easy to replace through inspection hatch. |

| Air contact | One side of the sheet is oil and the other is air, hence no contact. | Oil surrounds the bag and air is inside the bag, hence no contact. |

| Reliability | Very robust with zero risk of tangling. | Very effective and widely used in large units. |

This article is a part of the Transformer page, where other articles related to the topic are discussed in details.