AMI or Advanced Metering Infrastructure is a system of metering, which is incorporated of smart meters, communication networks and data management systems that enable two way communication between the power utility and consumers. AMI is the digital backbone which pushes the utility’s operation to the end point of the distribution network which is consumer’s premises. AMI is a standard based metering system which is capable of automatic data collection, remote operation and perform advanced metering analytics for power system management.

Table of Contents

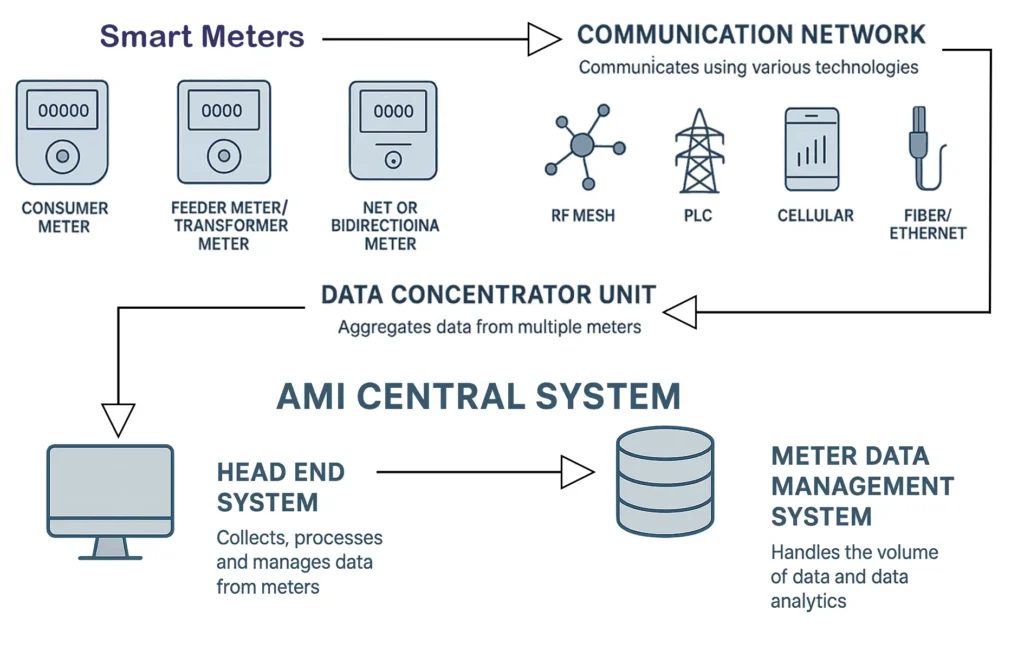

Key components of AMI

AMI is a complex integrated system with tiered architecture. Hence, understanding its key components unlocks its important role in the grid modernization.

Smart Energy Meters

These are the end point of the AMI network, which are responsible for measuring and communicating the energy data along with other electrical parameters. These are usually digital, bidirectional meters, with self processing capabilities. These are widely divided into:

Consumer meter: It measures electrical parameters at consumer’s premises be it a residential, commercial or industrial setup. It collects the data at a interval of say 15 minutes and computes total consumption, voltage quality and event logs like tamper and power outage. It includes a communication module and a service switch for remote disconnection/connection.

Feeder or Transformer meter: These meters are installed at a higher level in the distribution network at points like substation feeders and individual transformers. It collects and provides the data of energy flowing into a wider area or consumer cluster. The data of these meters are crucial for loss management, calculating the difference between feeder meter’s data and sum of consumer meter’s data of that specific feeder downstream. Also, the transformer meter’s data is essential to monitor the health of the transformer.

Net or bidirectional meters: These meters are specifically designed for consumers who consumes and also produces energy and puts it back to the grid like the distributed generation of solar rooftops. These meter logs energy in both direction import and export and maintains separate registers for the net billing. These meters are also used as substation feeder meters for the feeders where import and export of energies occurs.

Communication network

It is a secure two way bridge which connects millions of meters in the field to utility’s data center often tiered as Home Area Network (HAN), Neighbourhood Area Network (NAN), Wide Area Network (WAN). The common technologies used are:

RF mesh: It is a decentralized, self healing network where each meter behaves as a receiver, router and transmitter making the data to hop from one meter to another until it reaches the Data concentrator unit (DCU) or gateway. It is a very reliable, optimized technology which offers excellent coverage in dense, urban areas where it is difficult to make wired connections.

PLC or power line carrier: It is an existing concept of networking or transmitting data by the power lines itself. No new wires are required for data transmission, leveraging the existing physical infrastructure. But this technology is sensitive to line noise, and transformers. In distribution transformers the impedance varies with the frequency and high frequency PLC signals are significantly attenuated across transformer windings. Hence, PLC signals do not pass through transformers.

Cellular networks 4G/5G/LTE: This technology used for meter communication. New standards like the narrowband IoT are optimized for low power, wide area coverage with minimal use of data. It can be deployed faster, offers high bandwidth for larger files for firmware updates, is more reliable for remote and scattered meters. The disadvantages are only higher usage charges and dependency on a third party network service.

Fiber or Ethernet: It is used for high speed, high bandwidth applications usually for connecting the DCU of large industrial or substation meters directly to the Head End System of the AMI.

Data concentrator unit

The DCU also called as collector or gateway is the hardware that bridges the field meters and the utility’s IT system. It collects the meter data from all the down stream meters using communication technologies as explained above. It aggregates and compresses the data thereby forwarding the same to Head End System using a wide area network (WAN) like cellular or fiber or ethernet. The DCU reduces the load on the central system by being the local connection point for data filtering.

AMI Central System

The central system of advanced metering infrastructure comprises of powerful software application to handle data acquisition, processing and distribution of output to other utility business systems. It incorporates:

Head End System: It functions as the central communication server, managing two way flow of information with the DCU and meters. The HES is responsible for securing the data stream, scheduling the readings, sending commands for remote disconnection and managing the status of the devices. The HES acts as a gatekeeper or hub for the communication of AMI network. It stores the raw meter data received from DCU temporarily before passing it to Meter Data Management System for complex processing of data.

Meter Data Management System: It functions as the data processing unit of the AMI. It receives the raw data from the HES and transforms the raw meter data into actionable, auditable information required for billing, operations and regulatory reporting by performing core functions which are VEE, Processing and storage.

VEE or Validation, Editing and Estimation essentially means checking the data quality, identifying missing data points, correcting the errors and filling the missing data using algorithms. The MDMS calculates the billing determinants and does the load forecasting while managing complex tariff rules. Besides this, it stores the cleaned high resolution interval data for long term.

Core functional capability of AMI

Remote meter reading: AMI automatically reads and transmits highly granular energy consumption interval data (5,15, hourly) along with various electrical parameters like voltage, current, PF and etc from meter to MDMS. It eliminates costly and manual meter reading and provides time stamped system information for metering analytics.

Remote command: It allows the utility to remotely connect and disconnect electricity service to a consumer without a crew visiting the premise. This is achieved by the communication command sent from utility’s end to the internal service switch placed inside the meter. It reduces the time and cost associated with connection and disconnection for non payment. It also increases operational efficiency.

Outage detection: When power is lost, the internal battery of the meter powers its communication module and sends a last gasp signal to the utility system and when power is restored it sends a first breath signal. This enables real time outage notification to the utility and allows it to act swiftly for restoration of power with pin point location accuracy reducing 20-40% of the restoration time.

Firmware and configuration management: The two way communication of the AMI allows the utility to remotely manage millions of meters in the field. Command can be sent to the meters via the HES to remotely install new operating software versions and fix bugs and update configuration settings like interval data reporting frequency, time synchronization and tariff structure parameters. It ensures and extends the meter’s life and makes it secure and compliant to latest and relevant standards minimizing the operational expenditure.

This article is a part of the Metering page, where other articles related to the topic are discussed in details.