Accuracy class of energy meter actually indicates the maximum possible error that is acceptable in the measurement of energy consumption. Essentially it means how precisely the measured value agrees to the true value of energy consumption under various working conditions.

The maximum possible error in context to accuracy class of energy meter is the greatest deviation between the registered value of energy consumption in the meter and the true value of energy consumption. Different standards such as IEC defines the accuracy class of energy meter for the metering reliability. Typical accuracy classes of energy meters are denoted by 0.2s, 0.5, 1, 2. The lower the number is, the higher is the accuracy of the energy meter.

Table of Contents

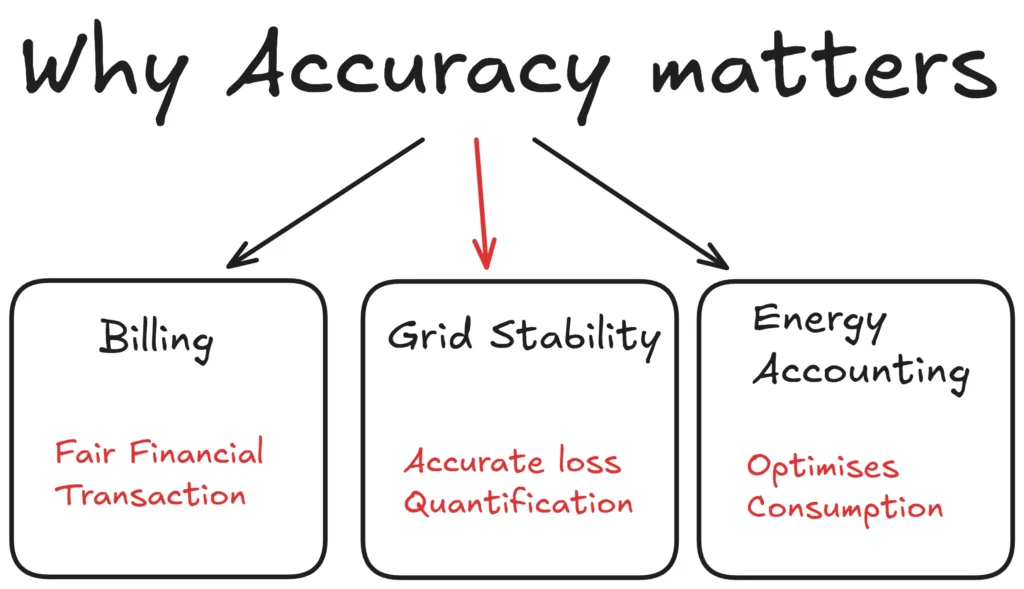

Why accuracy class of energy meter matters?

Accuracy in metering is among the most important things in the electrical industry which influences critical functioning, fairness, finances and system efficiency.

Billing: Accuracy class of energy meter directly impacts the billing of the electricity consumption which has a direct effect on the financial transactions. Accuracy class of the energy meter is essential for ensuring fair trade of electricity between the companies and consumers.

If the meter measures more energy than consumed, it results in a positive error, leading to over billing and the consumer faces financial loss. If the meter measures less energy than actual consumption, it results in negative error, resulting in revenue loss for the utility. Thus, accuracy class of energy meter help prevent financial losses both for consumer and utility.

Grid stability: High accuracy class of energy meter is essential in electrical network nodes like power plants, substations. It helps in quantifying the energy losses both technical and non technical. Precise measurement of energy helps to sustain grid stability by balancing the supply and demand. Inaccurate readings can often lead to imbalances, affecting the power quality and can potentially cause outages.

Energy meters installed at the points where the energy ownership changes hands like generation to transmission or transmission to distribution requires highest accuracy class of energy meters because of very high value financial transaction.

Energy accounting: Business and industries requires accurate energy consumption data to have an energy audit for identifying high consumption areas and implement efficiency measures. For distributed generations or renewable energy integration like solar and wind, high accuracy class of energy meter is essential for recording the import and export for proper energy accounting.

Common Accuracy class of energy meter

| Accuracy Class of energy meters | Maximum Permissible Error | General Application |

| 0.2S | 0.2% | Substations, generating stations. CT, PT operated. |

| 0.5S | 0.5 % | HT Commercial and industrial metering. CT, PT operated. |

| 1 | 1% | General industrial and commercial metering. Direct connected. |

| 2 | 2% | Residential and small commercial metering. Direct connected. |

Significance of S Class

The suffix S as seen in 0.2S and 0.5S stands for special accuracy. It denotes that this class of energy meters maintains the specified accuracy even at very low load currents.

For non-S class meters, the accuracy or maximum possible error of the meter is guaranteed for currents from 10% of the rated current to maximum current. Below the 10% of rated current the accuracy of these meters can suffer significantly.

For the S class meters, the maximum possible error covers a wider range from 1% of the rated current the accuracy of the meter is guaranteed. This is useful for high value metering points as the meters offers best accuracy even for lightly loaded cases which is often seen at large industries and substations.

How is the accuracy class of energy meter defined?

The accuracy is defined by the maximum permissible error, which is basically the limit for the meter’s measurement error. This limit is tested for various operating conditions including different current levels and influence of other external factors.

Mathematically, the percentage error is e = (Em-Et) / Et x 100%,

Where Em = Energy measured by the meter,

Et = True value of the energy consumed.

Maximum permissible error at reference current: This signifies the fundamental test point, where a basic test current or rated current is set with unity power factor. The maximum permissible error at this point represents the meter’s core accuracy at nominal conditions.

Maximum permissible error at minimum current: This point checks the meter’s sensitivity and its ability to accurately register the energy consumption at very low loads. IEC-62053 recommends the error of the meter to remain within the class limit at even lowest percentage of the rated current. The accuracy of the S class meters holds true for up to 1% of the rated current.

Maximum permissible error at maximum current: This point verifies the performance of the meter under heavy load current, ensuring that heating of the meter’s internal elements do not causes the meter error to go beyond the class limits.

Effect of power factor and temperature

The maximum permissible error is often considered as a single value under the nominal conditions but it is a set of error limits under different operating conditions.

Power factor: Meters are tested at unity power factor and at non unity power factors to check for the drift in accuracies. At the unity power factor, the error limit is often tighter but is relaxed at the non unity power factors to account for the additional phase shifts.

For example, at unity PF, a class 1 meter gives a ± 1% error while it gives 1.5% error at 0.5 PF. At PF =1, there is no effect on the active energy, but at a PF = 0.5, there is a significant change in the cos ϕ and so in the active energy. If the actual angle is 60 ° and because of the meter error it measures 59 °, the PF changes from 0.5 to 0.515. therefore, for 1 ° phase error, the active energy can change up to 3%. Hence, a tighter accuracy cannot be guaranteed at lower PF. It may be noted that modern class 1 meters have a phase angle error of 0.1 ° to 0.2 °.

Temperature: Every electronic component inside a meter be it a resistor, transformers, capacitors, ADC, oscillator crystals behave differently with the temperatures. As the temperature rises, resistance changes, ADC gain drifts, crystal frequency shifts etc.

The maximum permissible error for the class of meters is guaranteed usually at a range of 15° -25° C because at this range the component drift is minimal. But the meters are tested at -40 to +70 ° C with an additional percentage error in this range. However modern meter uses temperature compensated gain control, RTD sensors inside the meter and DSP based coefficient correction to maintain maximum permissible error at the class limits even at -40 to +70 ° C temperature range to make the meter commercially viable.

External influence

The influence quantities are external electrical and environmental factors which affect the meter’s measurement accuracy. The additional error caused by these factors are called critical change values.

Voltage variation: If the supply voltage changes outside the nominal range of voltage, it effects the internal ADC scaling, shunt heating and DSP sampling. The meter must maintain accuracy with in the maximum permissible error when voltage varies with in 10-20% of the nominal voltage.

Frequency Deviation: When the frequency deviates from the nominal frequency, it effects the digital sampling rate, zero cross detection and filter response. As per standard recommendation, meters must maintain accuracy with a small additional error when the frequency is varied by ± 2% of the nominal frequency.

Harmonics: The presence of non sinusoidal wave form causes the RMS and power computation more complex with introduction of phase dependent errors. The standard says the meter must compute the active energy accurately in presence of harmonics up to a tested THD level with small additional error.

Additional Error

It is the error that meter produces when tested under the influence quantities. It is denoted by δ = error under influence – error at nominal condition. The absolute value of δ must be less than the limit specified by the class of the meter.

For example, for class 0.2s meter, δ ≤ 0.1% , for class 1 meter δ ≤ 0.5 %

| Influence Quantity | Test Condition | Class 0.2S | Class 0.5S | Class 1.0 | Class 2.0 |

| Voltage Variation | ± 10% nominal voltage | ± 0.1% | ±0.2% | ±0.4% | ±0.8% |

| ± 20% of nominal voltage | ±0.2% | ±0.4% | ±0.8% | ±1.2% | |

| Frequency Deviation | ± 2% of nominal frequency | ±0.1% | ±0.2% | ±0.4% | ±0.8% |

| Harmonics (Waveform) | ±10% of 3rd Harmonics in current circuit | ±0.1% | ±0.2% | ±0.3% | ±0.6% |

| Reverse Phase Sequence | For 3-phase meters | ±0.2% | ±0.4% | ±0.8% | N/A |

| DC in AC Circuit | DC component in current circuit | ±0.1% | ±0.2% | ±0.4% | N/A |

| External Magnetic Field | 0.5 mT | ±0.2% | ±0.3% | ±0.6% | ±1% |

The above table is based on IEC 62053 standard.

This article is a part of the Metering page, where other articles related to the topic are discussed in details.