XLPE cables (Cross-Linked Polyethylene) are power cables which uses cross-Linked polyethylene as the cable’s insulation for an enhancement in thermal, electrical and mechanical properties. This technology in power cable developed in the late 1950s as an improvement over the existing PVC and the paper insulated cables. XLPE cables offer superior resistance to heat and excellent dielectric strength. The cross linking forms a strong molecular bond, which offers a continuous operating temperature range of up to 90 degrees Celsius and 250 degrees Celsius during faults. These cables are widely used in substation’s power distribution circuits, underground transmission system, offering high durability and light weight design.

Table of Contents

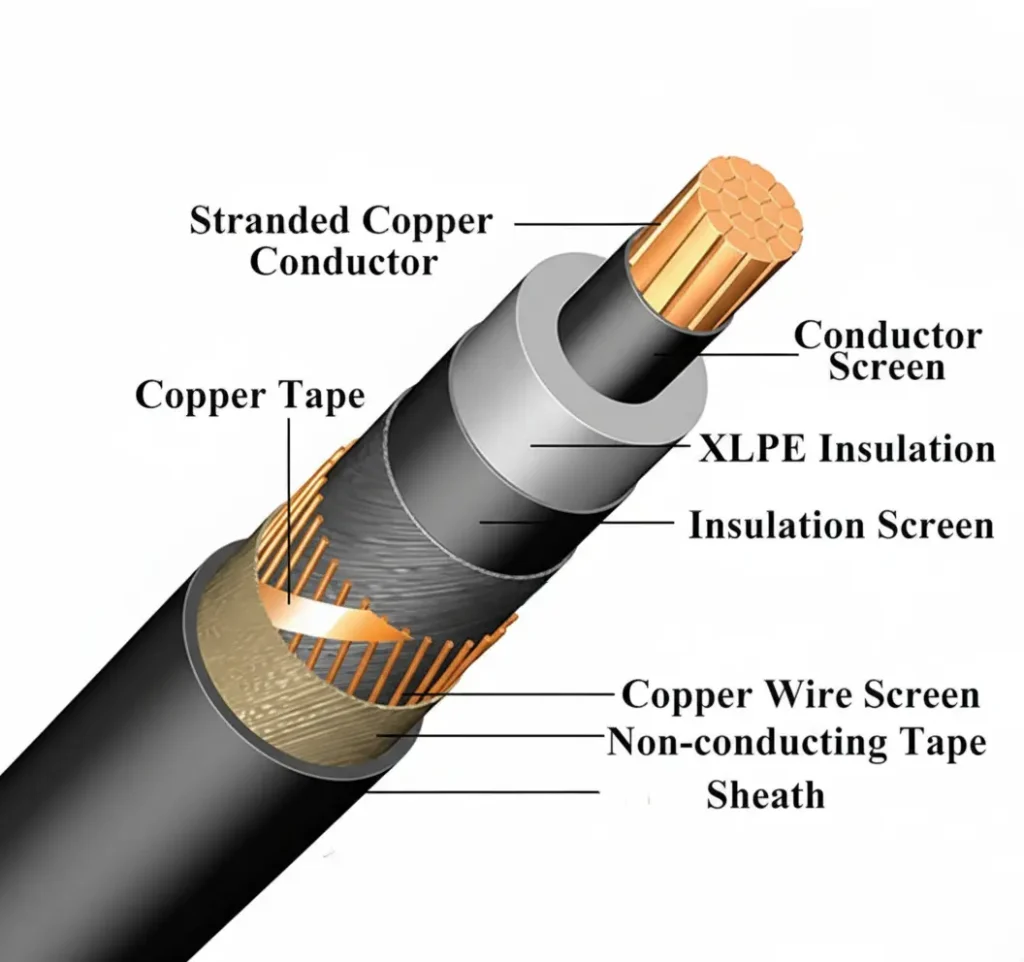

Construction of XLPE Cable

Core: The core of the XLPE cable is basically made from aluminium or copper. The conductor can be solid if the size is less than or equal to 10 mm2 or stranded above the size of 16 mm2. The stranding of the conductor enhances both flexibility and conductivity. The cross-sectional area ranges from 1.5 mm2 to 2000 mm2. The conductor can operate maintaining optimum performance up to temperature of 90 degrees Celsius, 130 degrees Celsius for emergency overloads and 250 degrees Celsius for a short time period, during short circuit faults.

Insulation: The XLPE cable’s insulation layer provides electrical and thermal performance. It complies with IEEE 404 requirements for thermoset materials. The dielectric strength of the XLPE cable exceeds 25 KV/mm with a thermal endurance limit of 90 degree Celsius. The typical thickness of the insulation varies from 1.14 mm (5 KV) to 8.89 mm (35 KV). The insulation of the XLPE cable insulation resists moisture, partial discharge, and corona which enhances the service life of the cable.

Screening Layer: The screening layer also called as stress control layer essentially includes a semiconducting conductor shield, a insulation shield and a metallic screen (copper tape or wire). IEEE 575 specifies shielding for proper electric field control. The metallic screen is used for providing a path to the fault current with a fault current capacity of 10 KA for 1second. It also provides electrostatic shielding between phases and to provide uniform electric field around the insulation of the cable. The equivalent cross sectional area of the metallic screen ranges between 10 to 35 mm2.

Sheath and Armor: As per IEEE 404, the inner sheath of XLPE cable is made from extruded PVC or polyethylene which gives the cable mechanical strength and moisture protection capability. Armour of the cable is usually made of galvanized steel wire or tape placed between the inner and outer sheath provides mechanical protection to the cable from crushing, direct impact forces and rodent damage. The armour is also capable of grounding the earth fault current safely in case of insulation failure.

The outer sheath in compliant to IEEE 1202 flame test is made of High Density Polyethylene (HDPE) or Low Smoke Zero Halogen (LSZH) as it offers UV protection, abrasion resistance and flame retardancy to the cable in harsh environment.

Working Principle

The working principle of the XLPE cable is based on the need for efficient power transmission through the conductor while providing complete electrical isolation between the surrounding by the use of cross linked polyethylene insulation. At the molecular level, the three dimensional bonds forms between cross linking polyethylene prevents the cable from melting and deforming at higher operating temperature limits up to 90 degrees Celsius.

The structure also enables uniform electric field distribution across the insulation, minimizing partial discharge and dielectric loss. Also, the cable’s dielectric strength above 25 KV/mm ensures minimal leakage current. During short circuit, high electromagnetic force acts on the conductor, the armour restricts the deformation. Overall, the XLPE cable provide reliable and stable performance for both AC and DC power transmission.

Properties of XLPE cable

High insulation resistance: XLPE Cables have a insulation resistance of over 1000 MΩ which ensures minimal leakage of current and provides superior insulation integrity under high voltage and humid environmental conditions.

Dielectric strength: XLPE cables have excellent voltage withstanding capability of around 30-40 KV/mm, preventing electrical breakdown while maintaining insulation performance under extreme electrical stress.

Operating voltage: The operating voltage of these cables ranges from 650 volts to 500 KV covering low voltage distribution to high voltage power transmission ensuring wide application across various power networks.

Low dielectric loss tangent: These cables have a tan δ ≈ 0.0002 which helps in minimizing power loss and heating. It enhances the overall cable efficiency and service life of the cable.

Temperature rating: These cables have a operating temperature limit of 90 degrees for continuous full load operation without any degradation in the physical state of the cable maintaining the insulation reliability. For emergency overloading, these cables can withstand 130 degrees Celsius for short period of time without any insulation damage. XLPE cables are also capable to withstand short circuit thermal stress for a very short duration with temperatures up to 250 degrees Celsius without any catastrophic cable failure.

Tensile strength: These cables have a tensile strength of 15 MPa approximately, which provides sufficient mechanical strength to withstand pulling and installation stress without any plastic deformation in the cable.

Elongation at break: It is the % increase in length before breaking, when subjected to tension. The XLPE cables have a 200% elongation at break, which implies high flexibility and ductility preventing any mechanical failure during installation.

Thermal expansion: These cables have a thermal expansion coefficient of 2 × 10⁻⁴ / °C approximately which means a expansion in length of 0.02% can be expected for every 1 degree Celsius rise in temperature. This maintains the dimensional stability of the cable during temperature variation.

Moisture, chemical and UV resistant: The cable is moisture resistance as the inner sheath is made from extruded PVC or polyethylene, the outer sheath also provides the cable chemical and UV resistance properties.

Minimum bending radius: The cable’s minimum bending radius is around 12 times the size of the cable diameter, which prevents mechanical and electrical stress concentration, ensuring safe bending with insulation integrity.

Advantages and Limitations

| Advantages | Limitations |

| XLPE cables have higher current carrying capacity compared to PVC. | At high stress concentration points, the cable is subjected to partial discharge. |

| The cable has excellent thermal and chemical resistance. | The cable is expensive than PVC cable of same rating. |

| The cable offers maintenance free operation. | It requires careful jointing and termination. |

| There is no need for oil filled insulation. | The cross linking process is critical and must be precisely controlled. |

Applications:

- These cables can be used for terminal connection of power transformer at HV and LV sides.

- It is extensively used for connection between cable feeders and switchgear panel.

- XPLE cables are often used in power transmission in urban areas.

- It is suitable for underground distribution of power.

- It also finds its application in renewable energy integration in compact substation.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.