PVC cable (polyvinyl chloride) is widely used cable insulation and sheath material since 1940s for its excellent durability, flexibility and cost effective solution. PVC cables offers very good electrical insulation while providing the required mechanical strength, resistance to moisture, chemical and abrasion, making its application, suitable in harsh environment. PVC cables are ideal choice for application as a low to medium voltage power and control cable. Also it is the most used cable in the building wiring. Although, several new technologies and insulation materials have emerged in present days, PVC cable’s application has not dropped because of the ease of processing it, flame retardant properties and considerable low cost compared to other cables.

Table of Contents

Construction

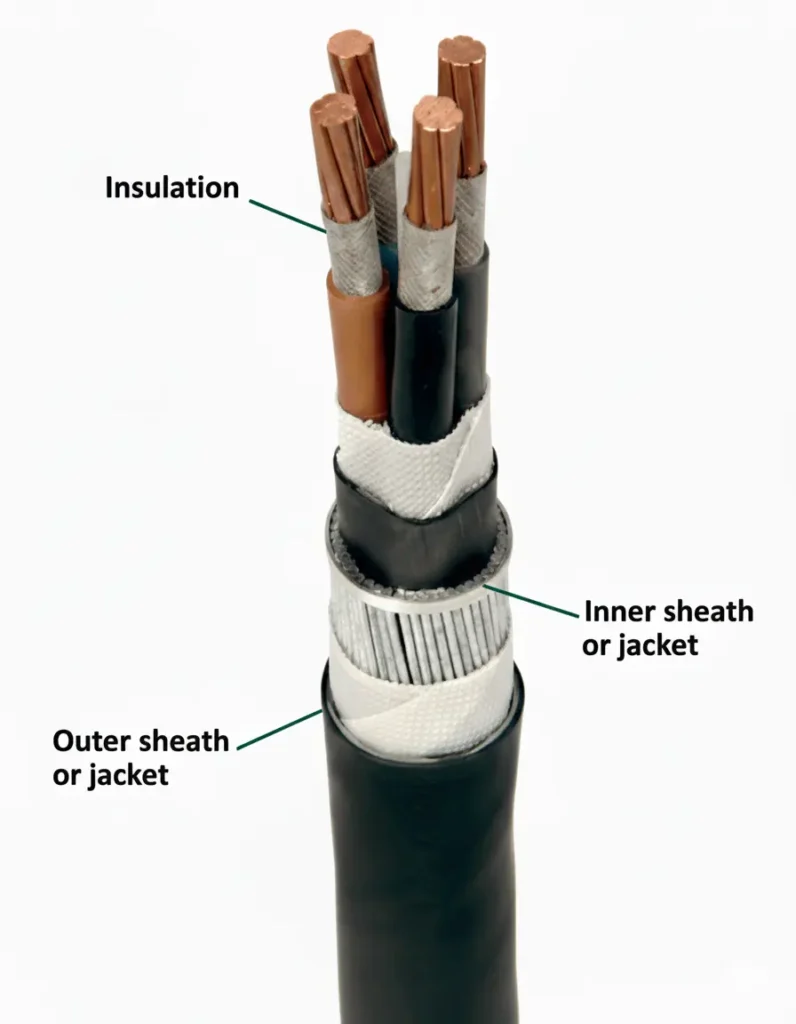

Conductor: The conductor in PVC cables are typically copper or aluminium, which is selected based on the required conductivity and cost consideration. The conductor can either be solid or stranded, the stranded conductor has an added advantage of being more flexible. The most common crossectional area of the conductor ranges from 1.5 mm2 to 630 mm2.

Insulation: The insulation layer of PVC cables are made of extruded PVC (polyvinyl chloride) compound that provides both electrical isolation and mechanical strength. The grade of PVC used, varies with the temperature rating of the cable. The thickness of insulation ranges from 0.7mm (for 1.5mm2 cable) to 3.6 mm (for 630 mm2 cables). PVC cables exhibits a practical dielectric strength between 18-22 KV/mm, as reported in ASTM D149 and IEEE 66 dielectric tests. The insulation can easily resist moisture, chemicals and oil. As per IEC 60227-3 and IEC 60502-1:

- Type A PVC cables (normal duty) are rated up to 70 °C,

- Type C PVC (heat resistant) are rated up to 85 °C and

- Heat resistant PVC cables (high temperature grade) are rated up to 105 °C.

Inner sheath: The inner sheath of PVC cables, popularly known as bedding, is also an extruded layer of PVC which is applied over the insulated cores in order to maintain a circular shape and also provide required mechanical protection. The thickness of the inner sheath ranges between 1 mm to 1.8 mm considering the number of cores and cable size. The inner sheath provides protection to the cable during armouring from any damage, while it also ensures the stability of the core under bending stress.

Armour: This layer in the cable is used for mechanical protection of the cable from impact forces and crushing forces. The layer contains galvanized iron wires or steel tapes, laid helically over the inner sheath. Nonmagnetic armour wires are used commonly for single core cables as the core produces single electromagnetic field that would otherwise overheat the cable resulting in power loss. While Magnetic armour are used for multicore cable protection as the electromagnetic field largely gets cancelled out.

The thickness typically ranges from 0.9 mm to 3.5 mm depending on the size of the cable. The overall tensile strength of the cable is increased by the armour and it also helps the cable to withstand the stresses during installation. The armour must pass the 3.5 KV AC test for 5 minutes as per IEC 60502-1, which ensures that the insulation and inner sheath can effectively isolate the live cores from the metallic armour which would remain grounded during operation.

Outer Sheath: The outer sheath of the cable is also made up of extruded PVC compound. This layer protects the cable from the harshness of the environment, mechanical and chemical stress. The thickness of this layer varies between 1 mm to 3 mm depending on the cable diameter. This layer resists the UV radiation while resisting moisture, and oil and maintaining flexibility of the cable between -15 °C to 70 °C. In some variants of the PVC cables, chemical additives like antimony trioxide and aluminium trihydrate are added to the outer sheath to make the PVC cable flame retardant for enhanced fire safety.

AS per IEC 60502-1

| Conductor Size (mm²) | No. of Cores | Fictitious Diameter under Armour (Du) mm | Inner / Separation Sheath Thickness (mm)* | Armour Type | Nominal Armour Wire/Tape Size | Outer Sheath Thickness (mm)** | Notes |

| 1.5 – 6 | 2 – 5 | 10 – 15 | 0.9 (0.02 Du + 0.6) | SWA | 1.25 mm wire | 1.4 | Light mechanical protection |

| 10 – 16 | 2 – 5 | 15 – 20 | 1.0 (0.02 Du + 0.6) | SWA | 1.6 mm wire | 1.8 | Standard power cable |

| 25 – 50 | 2 – 4 | 20 – 30 | 1.2 (0.02 Du + 0.6) | SWA | 2.0 mm wire | 1.8 | Typical for distribution feeders |

| 70 – 95 | 1 – 3 | 30 – 40 | 1.4 (0.02 Du + 0.6) | SWA | 2.5 mm wire | 2.0 | For substations / HV panels |

| 120 – 185 | 1 – 3 | 40 – 50 | 1.6 (0.02 Du + 0.6) | SWA | 3.15 mm wire | 2.3 | Heavy-duty construction |

| 240 – 300 | 1 – 3 | 50 – 60 | 1.8 (0.02 Du + 0.6) | SWA | 3.55 mm wire | 2.5 | Typical for medium voltage distribution feeders (PVC) |

The formula for finding the size of the inner sheath is 0.02 Du + 0.6, where Du is the cable diameter under the armour in mm.

Where as the outer sheath thickness over armour is minimum 1.8mm or to ≥ 0.035D + 1.

Type of Armour used is SWA (steel wire armour) usually in practice for power cables up to 3KV.

Properties of PVC cables

Thermal rating: The thermal rating of PVC cables allows it to operate continuously at 70 °C for type A, 85 °C for type C PVC cable and 105 °C for type D or high temperature grade PVC cable. The PVC cables can also withstand a 160 °C for 5 seconds under short circuit conditions.

Dielectric Strength: PVC cables have a dielectric strength of around 18-20 KV/mm, which ensures reliable electrical isolation in low to medium voltage power and control circuit application.

Elongation at break: PVC compound allows a 150% elongation at break, which shows the elasticity of the cable, elongating 1.5 times before breaking or plastic deformation, which maintains the flexibility of the cable.

Thermal expansion: These cable’s have a linear thermal expansion coefficient of around 7 x 10-5 / °C, which ensures dimensional stability across varied temperature and loading conditions.

Flame resistance: PVC offers moderate flame resistance properties with self-extinguishing behaviour, which prevents the flame from spreading, thus ensuring a safer installation.

Advantages and Limitations

| ADVANTAGES | LIMITATIONS |

| Low cost and easily available | Limited thermal rating |

| Flexible and easy installation | Releases toxic halogen gas under fire |

| Moisture and chemical resistant | Quick aging and hardening up on exposure to sunlight and heat. |

Application

The PVC cable finds extensive application in:

- Domestic and commercial electrical wiring.

- Control and instrumentation circuits.

- Industrial power distribution up to 1.1 KV (Heavy Duty PVC cable).

- Widely used for temporary and portable installation like construction site lighting and powering machinery, exhibition and events power setups.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.