Grounding vs bonding is a very important topic for discussion as both deals with the connection of electrical system for creating a safe path for the fault current yet serve different purposes. Grounding connects equipment or system to the earth in order to stabilize the voltage and provide a reference point for earth or zero potential, with respect to which, every other voltage is measured. While bonding is a process of connecting two metal parts together, so that both maintains same electric potential.

In different installations, like substation, industries and domestic wiring, misunderstanding in grounding vs bonding can lead to shock hazards and equipment damage. Proper grounding ensures fault current flowing safely into the earth, while proper bonding eliminates the dangerous potential differences.

Table of Contents

Grounding vs Bonding

| Parameter | Grounding | Bonding |

| Definition | It connects the electrical system or equipment to the earth. | It connects two or more conductive parts together. |

| Purpose | It provides a low resistance path for the fault current to the earth. | It ensures all metal parts maintains equal electric potential. |

| Function | It stabilizes the system voltage and dissipates the lightning or fault currents to the earth safely. | It removes the voltage differences and prevents electrical shocks and sparks. |

| Safety role | It protects the system and equipment insulation. | It protects humans by eliminating the touch potential between two metal object. |

| Application | Used for transformer, generator, neutral grounding, equipment earthing, lightning protection. | Used in conduits, panels, cable trays, fences and metallic enclosures. |

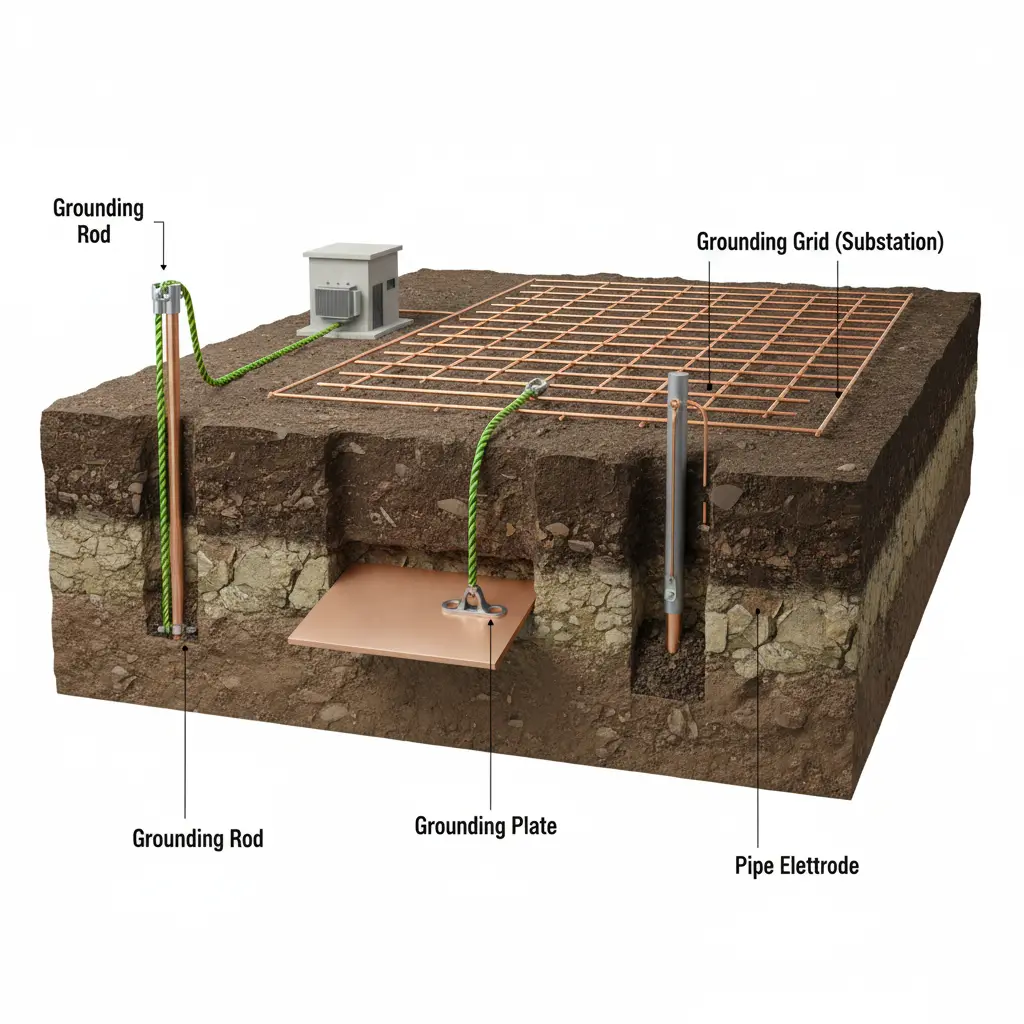

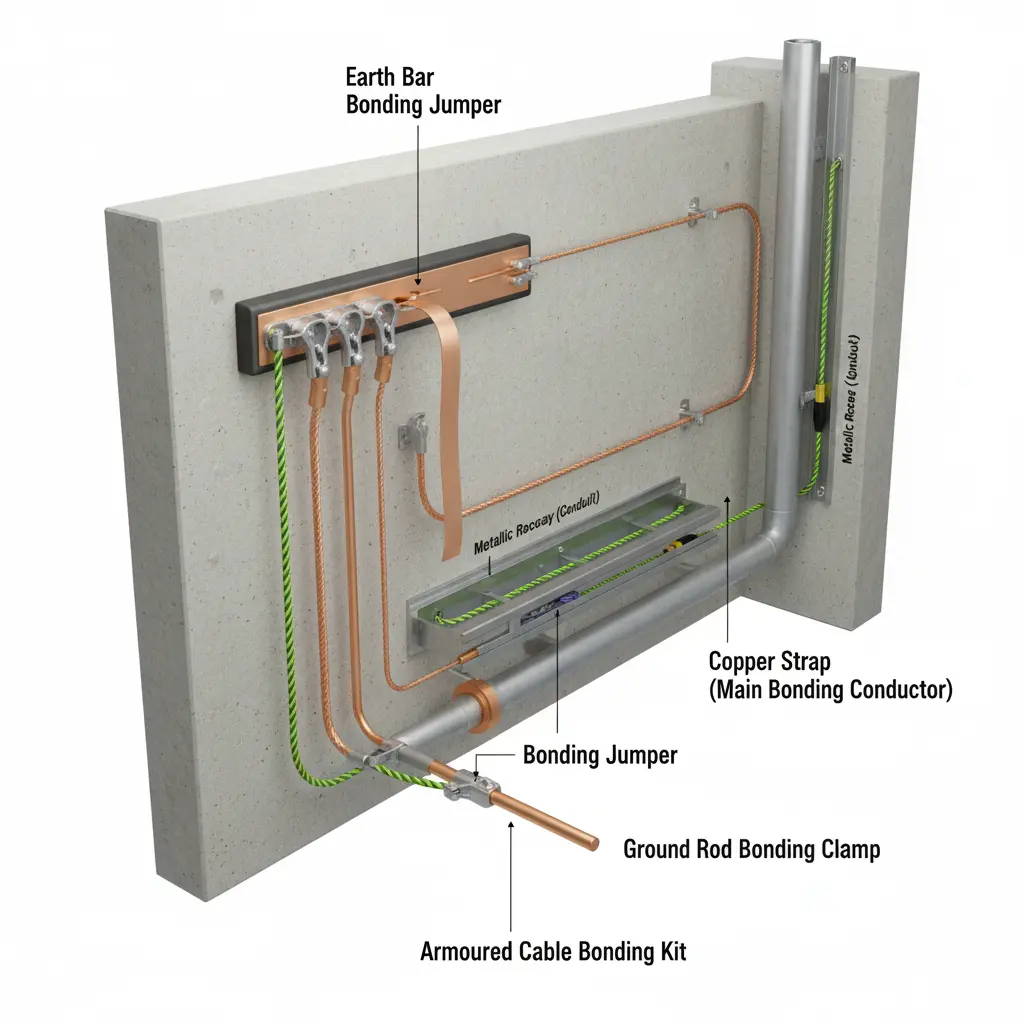

| Components | Ground rods, earth mats, electrodes, ground grid, grounding conductors. | Bonding jumpers, straps, clamps and metallic raceways |

| Measurement | Ground resistance (Ω) | Continuity (mΩ or Ω) |

| Failure Effect | Poor fault clearance, unsafe voltages | Shock hazard, arcing, equipment damage. |

Purpose, Grounding vs Bonding

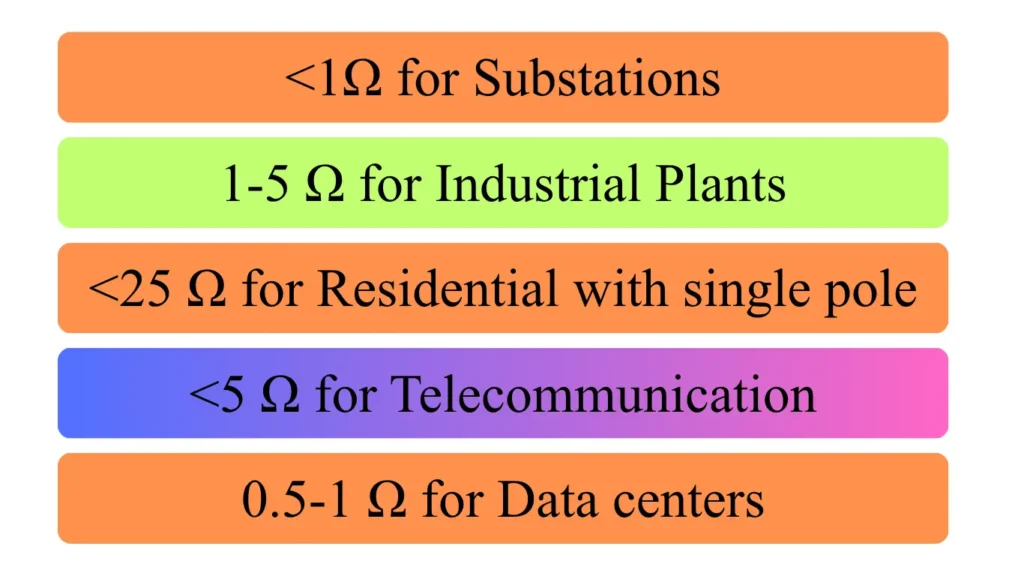

Grounding vs bonding, both have purposes which are distinct and complementary for the safe and reliable functioning of the electrical system. The purpose of grounding is to provide a low resistance path between the electrical system and the earth so that the fault current, electrical surge and lightning surge can easily dissipate in the earth without causing any dangerous potential rise in the electrical equipment, thus saving the insulation of the equipment. Grounding resistance is usually less than 1 Ω for electrical substations, 1-5 Ω for industrial grounding systems and less than 25 Ω for residential systems as recommended by National Electrical code (NEC) and IEEE-80.

The purpose of bonding is different. Bonding ensures that all metallic, conductive or structural parts within the installation are electrically connected to maintain equal potential. The main purpose here is not to send the current to earth but to eliminate the differences in voltage, which can cause shock hazard or arcing. In the electrical installation, bonding prevents dangerous touch voltages during faults and ensure that the relay, breaker and fuse operates accurately, as bonding connects equipment body to grounding conductor and to the grounding grid which creates a low resistance fault loop. During fault, high current flows through this loop and the protective device detects this current to trip instantly.

Function, Grounding vs Bonding

Functioning in grounding vs bonding is yet another point to learn. The function of grounding is to stabilize the system voltage. In an ungrounded system, the neutral point is free based on small leakage current and insulation capacitance. Because, the best of insulations also leaks tiny current, these currents have nowhere to go and it charges and discharges the phase to ground capacitance. This causes the neutral point to displace. In grounded system, the neutral is clamped to 0 volts as any excess charge flows to the earth but in case of ungrounded system, tiny leakage current can cause the neutral to shift tens or even hundreds of volts.

When a fault occurs in a grounded system, the grounding ensures that the current flows through the low impedance path, the high fault current triggers the protective devices and isolates the fault immediately.

On the other hand, bonding functions to connect electrically all the metallic and conductive parts so that they remain at a equipotential level. Bonding does not depend on earth, it eliminates the voltage difference between metal parts during the normal and faulty condition. As current will flow whenever there will be potential difference between metallic or conductive parts and increase the risks of shocks and arcing, bonding nullifies this risk by maintaining all metallic structures in same potential level.

Components, Grounding vs Bonding

The components can also be a differentiating factor in grounding vs bonding. The grounding components includes earth electrodes like rod, plate, pipe, chemical electrodes, earth mats for substations, grounding grid buried underground. It also includes ground enhancement materials like bentonite and charcoal-salt, grounding conductor (copper, galvanized iron or aluminium), earthing pit, neutral grounding reactor, lightning protection conductor and test links.

While bonding components includes bonding jumpers, copper straps, earth bar, GI strips, clamps, connectors, lugs, ground rod bonding clamps, metallic raceways, cable tray, conduits, armoured cable bonding kit and structure bonding links. In substation, all equipment like breaker structure, transformer tanks, marshalling kiosks, fencing, control panels and support structures are bonded with dedicated earthing conductors.

Application, Grounding vs Bonding

Grounding application covers almost all the power systems be it generation, transmission, distribution and industrial installations. In substation, grounding grids disperses the high fault current which controls the potential gradient to keep the operator and personnel safe. Transformers, generators, circuit breakers, surge arresters, lightning masts, all requires grounding for proper operation and surge protection. It is also essential for cable sheaths, neutral grounding, sensitive equipment like SCADA, where stable voltage reference is a must.

While bonding application includes connecting all metallic enclosures, cable tray, GI pipes, switchgear bodies, transformer tanks, fencing, structures and cable armouring. Bonding prevents the formation of static electricity on tanks, pipes and machinery. In substation, fences, rails, supports are bonded to avoid potential difference. Bonding is crucial in hazardous locations also to prevent arcing that could ignite flammable gases.

Effects of failure, Grounding vs Bonding

When bonding is poor or fails,

Fault current becomes very small and relay can fail to pickup, which will result in no tripping of the circuit breaker.

Without bonding, different metallic parts / structures will be at different potentials during faults and can cause severe electric shock when both surfaces are touched.

Poor bonding causes irregular current or noise which will lead to malfunctioning of the relay. Either relay will not send trip signal or send false trip signals.

If bonding between neutral and earth becomes poor, the neutral will shift from 0 Volt, which will cause the phase voltage to be unbalanced and because of which equipment can malfunction or overheat.

When grounding is poor or fails,

Fault current during fault will not return to the source, which will not activate the protective relay or breaker. It will cause the fault to stay on the system for long and increase fire and shock risk.

During fault, the equipment body should quickly discharge the fault current to the ground, if the grounding is weak, the equipment body will rise to dangerous voltages and touching it will result in fatal shock.

When large fault current enters poor grounding grid, the grounding grid potential rises sharply. This results in hazardous voltage difference between earth and nearby structures. High ground potential rise (GPR) can damage the equipment and expose personnel to dangerous voltages when they touch grounded structures or equipment.

Step potential is the potential difference between two feet of an operator during a fault. If the grounding is weak, fault current will not spread in the earth uniformly and it will create potential concentration in certain areas, thus increasing the step potential around the equipment.

This article is a part of the Safety and Earthing page, where other articles related to topic are discussed in details.