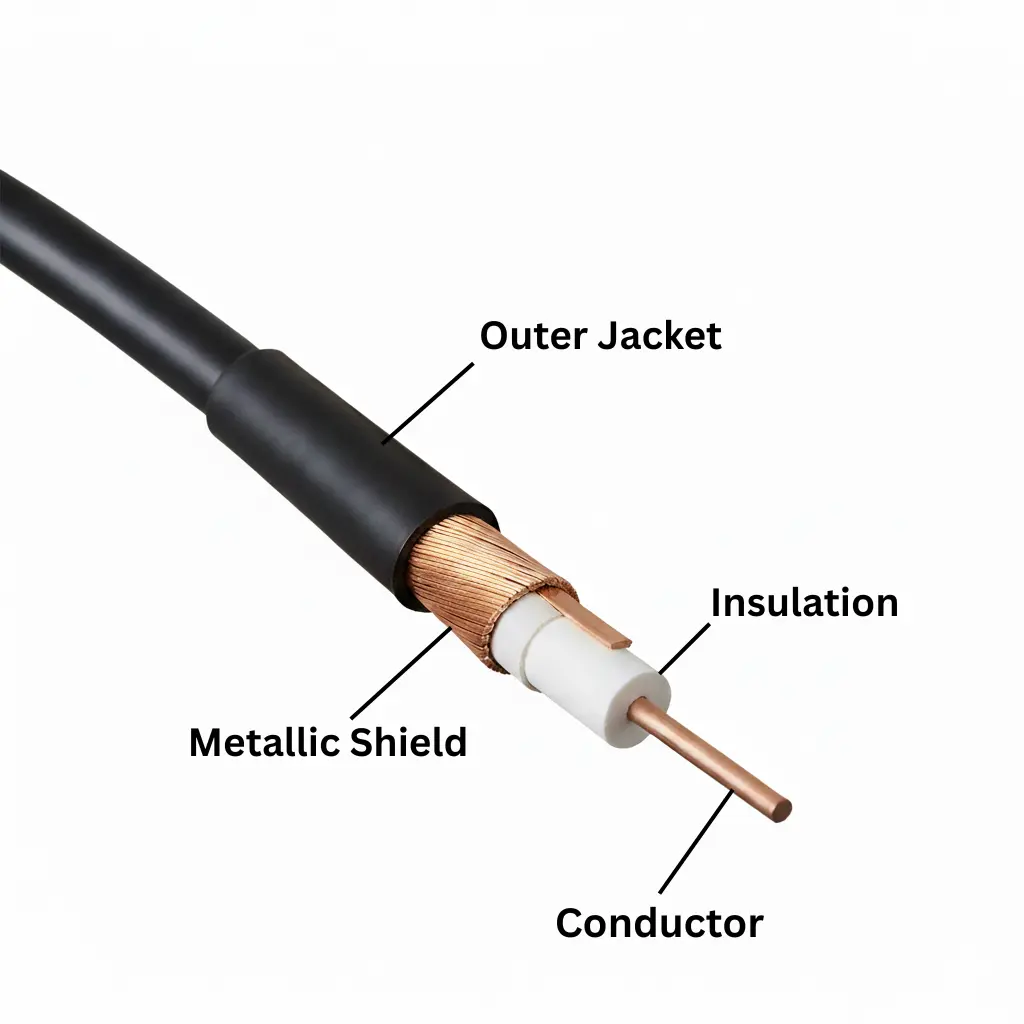

Coaxial cables are special electrical cable which are designed for carrying high frequency signals with minimum loss and also protect the signal against noise. The Coaxial cable contains a central conductor with a dielectric layer of insulation, metallic shield that is braided or with foil and an outer sheath that ensures physical protection. The cable is called coaxial cable because the conductor inside and the outer shield are at same geometrical axis, which results in uniform electromagnetic field that reduces interference and leakage of signal. These cables are widely used in telecom networks, RF communication, CCTV systems, broadband internet, etc, where stable signal transmission, with low noise and high bandwidth is the priority.

Table of Contents

Construction of the Coaxial cable

Central conductor: The inner conductor of the coaxial cable is usually solid or stranded copper or copper clad steel used for mechanical strength. The use of this conductor is to carry the high frequency RF signals with negligible loss. The diameter of the conductor controls the characteristics impedance and attenuation. High conductivity of the conductor material makes sure that the signal transmission is efficient, while the smooth surface finish ensures reduced skin effect losses at high frequencies.

A solid silver plated copper wire with a silver coating of 1µm is considered good as per IEC 61196 because 1 micro meter coating provides enough conductive layer for the skin effect current, it prevents surface oxidation and thus signal loss and it ensures consistent performance over the cable life.

| Feature | Solid Conductor | Stranded Conductor |

| Attenuation | Lowest | Slightly higher |

| Impedance Stability | Very Good | Good |

| Toughness During Flexing | Poor | Excellent |

| Best Use | Long fixed installations | Patch cords, portable cables |

Dielectric Insulation: The insulation layer made of solid polyethylene (PE) or foam polyethylene (PE) or Polytetrafluoroethylene (Teflon), which keeps the inner conductor perfectly in the center inside the shield. This layer maintains the cable impedance by maintaining a fixed distance between the conductor and outer shield. Low loss dielectric material reduces signal attenuation at high frequency. Foam PE has a lower dielectric constant which improves the bandwidth and reduces transmission loss.

Z0= (60/ √ϵr) ln(D/d)

Where, D is the diameter of outer shield,

d is the diameter of the inner conductor and

ϵr is the dielectric constant of the insulation.

Metallic shield: This shield can be braided copper or aluminium foil or foil and braid combination. It is used for blocking the electromagnetic interference ( EMI ) and it also provide a return path for the RF signals. Higher braid coverage improves the effectiveness of the shielding while the dual shield and quad shield design offers better noise rejection making it ideal for telecom system and RF system.

Outer jacket: The outer jacket of the coaxial cable is typically made from PVC, PE or Low Smoke Zero Halogen (LSZH). This jacket protects the cable from mechanical stress, abrasion, moisture and chemicals. The PE jackets is suitable for outdoor use for weather resistance and LSZH is preferred in buildings for its low smoke and low toxicity. This jacket ensures durability and long term environmental exposure. The typical temperature rating of this cable is -40 °C to 70 °C for PE jacket as per IEC 61196.

Working Principle

The coaxial cable operates by transmitting high frequency signals through the inner conductor while providing the controlled return path through the surrounding metallic shield. When RF or the high frequency signal is applied to the coaxial cable, the alternating current flows through the surface of the inner conductor of the cable because of skin effect. The return current flows through the inner surface of the shield creating a coupled transmission line.

The dielectric material of the coaxial cable lies between the conductor and the metallic screen, which is responsible for containing the electromagnetic field. As the field remains contained within the region of the dielectric, RF signal leakage is extremely low making the cable ideal for long distance and high frequency communication. The dielectric maintains electrical separation between the conductor and the screen, thus maintaining uniform impedance along the length of the coaxial cable.

The characteristics impedance of the coaxial cable is typically around 50 Ω to 75 Ω and is a function of the ratio between inside diameter of the shield to the inner conductor diameter. It is also a function of the dielectric constant of the insulating material, which is explained above. Thus, maintaining precise geometrical dimension ensures the proper signal propagation with low attenuation and minimal reflection. This helps the coaxial cable deliver noise free, reliable and interference free signal transmission.

Electrical Characteristics of coaxial cable

Characteristics impedance: The coaxial cables are designed with a precise characteristics impedance of 50 Ω for RF and instrumentation applications or 75 Ω for video broadcasting application.

Capacitance per meter: The capacitance varies with the thickness of the dielectric layer and material. General numbers are approximately around 80 pF/m for 50 Ω foam PE cable and 70 pF/m for 75 Ω cable. Lower the capacitance, improved is the high frequency performance of the coaxial cable.

Attenuation loss: Attenuation increases as the frequency and the cable size increase. Typically, a low loss 50 Ω coaxial cable shows 1.8 dB/100 m at 50 MHz , 4.5 dB/100 m at 400 MHz, and 8.2 dB/100 m at 900 MHz. Lower the attenuation, higher is the signal integrity over long distance in RF, cellular and microwave application.

Velocity Factor: It shows how fast the signal travels through the cable compared to the speed of light. Solid PE dielectric offers 66 % of c (c=speed of light) while foam PE dielectric offers 76 to 85 % of c. The velocity factor affects the timing, phase accuracy and antenna feed performance in RF communication, broadcasting and timing of critical systems.

Shielding effectiveness: It measures the resistance to external electromagnetic interference. High quality coaxial cable provides >90 dB shielding using foil and braided construction while quad shield cables can provide a greater shielding of above 100 dB. Higher shielding offers greater noise reduction, prevent signal leakage and ensure stable performance in high electromagnetic interference environment like substations, industrial plants etc.

Voltage rating: Coaxial cables has a defined insulation withstand level with a typical working voltage of around 600 V. There are also many RF grade cables providing 1.5 to 4 KV DC withstanding capability depending on the insulation and construction of the coaxial cable. Adequate rating of voltage ensures safe operation of the transmitters and instrumentation circuits.

Types of coaxial cables

Based on impedance

50 Ω cable: These cables are used for RF, radio transmitters and instruments. Examples of these cables are RG-8, RG-58, LMR-400 for efficient power handling.

75 Ω cable: These cables are widely used in TV, CAT V, CCTV, etc. Examples of these cables include RG-6, RG-59, RG-11 with low loss signal transmission.

Based on dielectric

Solid PE cable: This cable provides stable impedance and durability, used where moderate loss and consistent performance are desirable.

Foam PE: This cable has a lower dielectric constant which reduces the loss and improves high frequency performance and velocity factor.

Air spaced: It used air gaps with spacers and hence offers a very low loss and excellent high frequency characteristics.

Based on shielding

Single shield: It consists of one braid or foil layer only, it is used for low interference environment with basic electromagnetic interference.

Double shield: It consists of foil and braid combination, it has an improved shielding and used for telecom and RF installation.

Quad shield: It consists of two foils and two braid combination. It delivers maximum EMI protection and used for CAT V and RF systems which are sensitive.

Based on application

RF cable: These coaxial cable are used in antennas, transmitters and communication system involving high frequency RF power and signals,

CAT V cable: These are designed for cable television networks with low loss and high shielding.

High frequency microwave: These are used in radar, satellite and microwave links which requires ultra-low loss and precise impedance.

Various coaxial cable available

| Cable Type | Impedance | Size / Diameter | Flexibility | Attenuation | Minimum Bend Radius | Best Use / Applications |

| RG-59 | 75 Ω | ~6.1 mm | High | High | ≈ 10 × diameter (≈ 60–70 mm) | Short CCTV, low-frequency RF |

| RG-6 | 75 Ω | ~6.9 mm | Medium | Low | ≈ 7 × diameter (≈ 50 mm) | TV, DTH, satellite, broadband |

| RG-11 | 75 Ω | ~10.3 mm | Low | Very low | ≈ 10 × diameter (≈ 100 mm) | Long cable TV & internet runs |

| RG-8 | 50 Ω | ~10.3 mm | Medium | Low | ≈ 10 × diameter (≈ 100 mm) | Ham radio, HF/VHF, high-power RF |

| RG-58 (RF-58) | 50 Ω | ~5 mm | High | Medium–High | ≈ 5 × diameter (≈ 25–30 mm) | Radio antennas, instrumentation |

| LMR-400 | 50 Ω | ~10 mm | Medium | Very low | ≈ 25 mm (manufacturer spec) | Wi-Fi, LTE antennas, RF repeaters |

| Semi-Rigid Coax | 50/75 Ω | Varies | None | Very low | Fixed bend radius (single-form only) | Microwave RF, aerospace, radars |

| Hardline Coax | 50/75 Ω | 13–50 mm | Very low | Extremely low | 10–20 × diameter (100–400 mm) | Telecom towers, broadcast feeders |

Installation guidelines for coaxial cables

Maintain minimum bend radius: Follow the minimum bend radius of the coaxial cable in order to prevent impedance variation and long term dielectric damage.

Avoid crushing the cable: Crushing deforms the shield and the insulation of the cable which can increase interference and loss. Hence avoid tight cable ties and clips.

Do not remove excess shield braid: While stripping the cable, maintain maximum braid coverage to prevent signal leakage in sensitive RF and CCTV applications.

Use of proper connectors: Match the connectors like BNC, N type of F type to cable impedance and size for the reliable termination and stable performance.

Ensure proper crimping and compression: Use of proper calibrated tools to achieve firm and uniform crimping for minimizing signal leakage and improving return loss.

Keep away from power cables: Route the coaxial cables away from AC power lines to avoid electromagnetic interference and noise pick up.

Advantages and Limitations

| ADVANTAGES | LIMITATIONS |

| Minimal signal loss | Higher attenuation at long distances. |

| Offers great reduction in external noise. | The size is bulkier. |

| The impedance of the cable is stable. | Difficult installation in tight bends. |

| Allows high frequency transmission. | More expensive than unshielded twisted pair for networking. |

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.