Circuit breaker sizes basically refers to the current rating (ampere) that it can safely conduct without tripping during normal operation. It refers to the maximum continuous current carrying capacity of a circuit breaker without causing interruption in the power flow of the circuit preventing any sort of overheating or damage to itself and the circuit. For common domestic usage the rating can be 5A, 10A, 15A…., etc. However, the industrial circuit breakers are rated based on relatively much higher continuous current rating like 650A, 1250A,…, etc. The circuit breaker size determines how much of load it can cater to while providing adequate protection.

Table of Contents

For the industrial circuit breaker size, other than maximum continuous current carrying capacity, the voltage rating, operating cycle, short time current rating, current making and breaking capacities, arc quenching media all play a crucial role in the selection of circuit breaker. More the voltage rating, bulkier the industrial circuit breaker size is.

However, for domestic use, selecting the right circuit breaker size is a function and coordination between the circuit breaker, connected wire size and load demand only.

Importance in selection of right circuit breaker size

A correct circuit breaker size is important for safety and efficiency of the connected system. A undersized circuit breaker will trip more frequently and cause unnecessary power interruption, where as, a oversized circuit breaker may fail to trip the circuit during a fault, leading to electrical hazard, and equipment damage. The correct circuit breaker size protects the wiring and the connected appliance from overload, short circuit and improve the operating efficiency under normal loading condition. Proper circuit breaker size improves system reliability as well as reduces maintenance issues.

Relation between circuit breaker size, conductor size and the load current

The circuit breaker size, conductor size and the connected load current are interlinked for a safe and efficient electrical design. The rating of the circuit breaker must match with the capacity (ampacity) of the wire and the load current demand as well. If the wire or the conductor is too small for the connected load current, the wire will overheat and melt causing the circuit to interrupt.

Where as, if the circuit breaker is small compared to the load current, the breaker will trip repeatedly. For example, a 20 A circuit breaker will require a 12 AWG or 4mm2 wire and the continuous load current should be within 80% of the rating. Good coordination ensures safety, efficiency and long operational life.

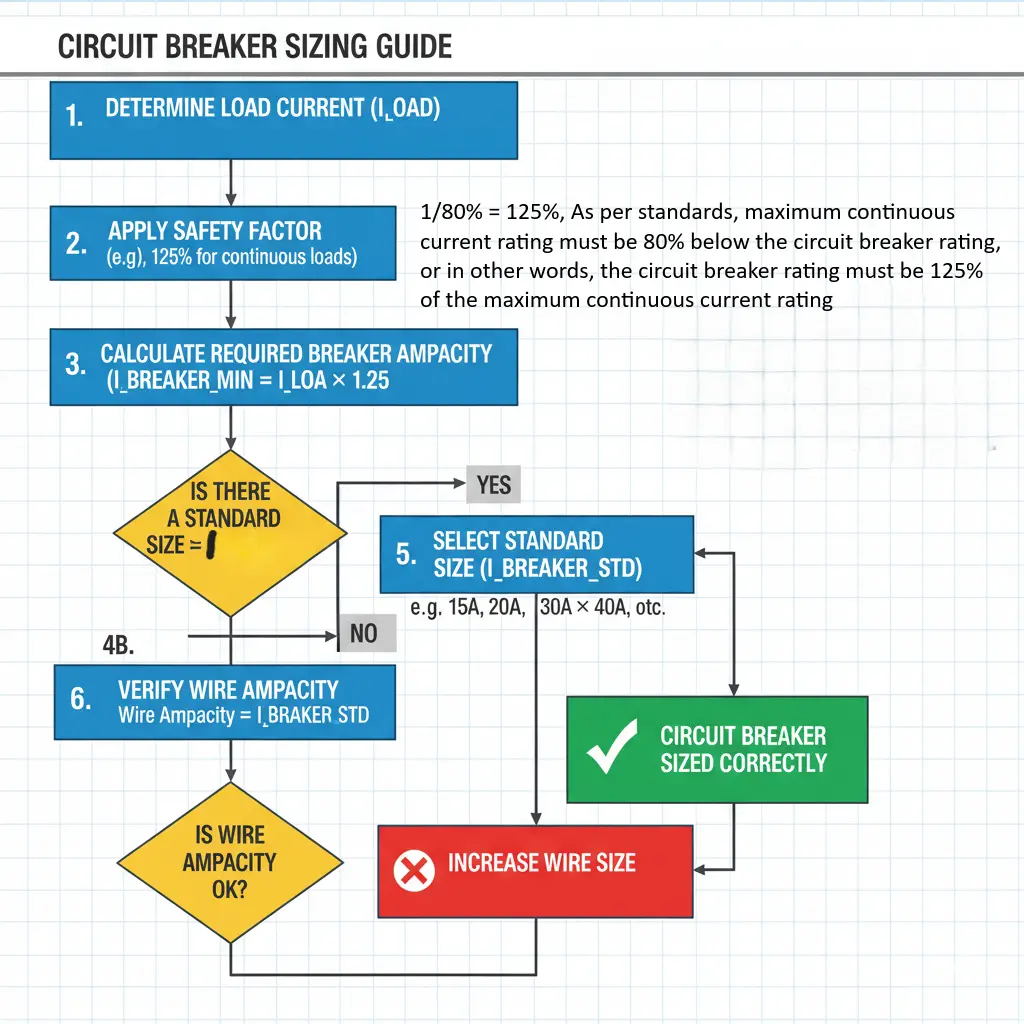

How to select the correct circuit breaker size

Selection of correct circuit breaker size is among the most important steps of designing and modelling an electrical circuit. The objective of the design is to ensure that the circuit breaker, connecting wire and the connected appliance shall safely handle the continuous electrical load (expected or maximum) without overheating and unnecessary tripping.

We can determine the load current using simple formula, I = P/V, where I = Current in ampere, P = Power in watts, V = Supply voltage in volts.

Example-1, in a 120 Volt system, if we plan to connect a 1500 Watt load, the load current in this case will be I = 1500/120 = 12.5 A.

According to the NEC’s 80% rule, the circuit breaker size must be that which carry below 80% of the rated current continuously. Therefore, circuit breaker size, = 12.5 / 0.80 = 15.6 A.

Therefore, according to the market availability, the ideal circuit breaker size will be a 20 A. It may be noted that a circuit breaker should never be selected undersized. The 20 A circuit breaker will be paired with a 12 AWG copper wire for safe operation.

Example-2, in a 230 Volt system, a 3000 watt load is to be connected, therefore load current, I = 3000/230 = 13.04 A.

Adding the 80% capacity rule, 13.04/0.80 = 16.3 A.

Therefore, the suitable circuit breaker in this case also will be 20 A circuit breaker paired with a 4 mm2 copper wire.

While selecting the circuit breaker size, it is to be made sure that a proper connecting wire size is selected.

Typical sizing of circuit breakers

| Breaker Size | Recomended Wire Size | Approx Wire Size | Common Loads | Remarks |

|---|---|---|---|---|

| 10A | 16 AWG | 1.5 mm² | Lighting circuits, small fans | Suitable for light household loads |

| 15A | 14 AWG | 2.5 mm² | Lighting + light socket circuits | Common in older or low-load homes |

| 20A | 12 AWG | 4.0 mm² | Kitchen outlets, small appliances | Most common household breaker size |

| 25A | 10 AWG | 6.0 mm² | Small air conditioners, washing machines | Requires separate circuit |

| 32A | 8 AWG | 6–10 mm² | Water heaters, large appliances | Often used for single heavy loads |

| 40A | 8 AWG | 10 mm² | Electric cooktops, small subpanels | Must ensure correct wire ampacity |

| 50A | 6 AWG | 16 mm² | Electric ovens, EV chargers | Typically for high-demand circuits |

| 63A | 4 AWG | 25 mm² | Industrial lighting, HVAC systems | Use only in heavy-duty installations |

| 100A | 3 AWG | 35–50 mm² | Main breaker for small buildings | Requires proper grounding and insulation |

Factors affecting circuit breaker sizes

Load type: The sizing also depends upon the type of load as a resistive load draws steady current, while inductive loads like motor causes a high inrush during starting. A motor circuit requires a circuit breaker sized higher than normal operating current (120-200%) to prevent unnecessary tripping during startups and overloads which are usually transient in nature.

Temperature and conductor length: High temperature causes the current carrying capacity of a conductor to drop down, and long cables increases the resistance there by decreasing current carrying capacity. This impacts the breaker’s performance causing unnecessary trips due to high temperature and voltage loss along the length of the conductor. Hence, while designing, proper derating factor must be used to counter this effect.

Voltage drop consideration: Voltage drop is caused when the connected appliance is placed at a far distance because of cable resistance. This causes under efficient performance of the appliance. The circuit breaker sizing therefore must account for acceptable voltage drop within commonly within 5%.

Location of installation: Circuit breakers installed in hot and closed panels with no ventilations loses thermal performance. Exposure to moisture, sun requires a weatherproof or high rated breaker. Panel type and enclosure class (IP rating) affects the breakers protection level.

Specialized circuit breaker sizes

Miniature Circuit Breaker (MCB) for small loads: MCB are compact in size and are commonly used for low current applications like lighting, outlets and small appliances. Usually rated between 0.5 A to 125 A, the MCB provides quick and effective protection against overload and short circuit.

Moulded case circuit breaker (MCCB) for high current: MCCBs are used in high current application usually rated between 100A to 2500A and are mostly used in commercial and industrial applications. The MCCB offers adjustable trip setting for overload and short circuit protection.

Industrial Breakers: These breakers allow fine tuning of trip settings which match specific load requirements. They are used for industrial systems where equipment draws varying levels of current. These breakers have adjustable tripping mechanism with an electronic trip unit for thermal as well as instantaneous magnetic tripping for protection of large motor, transformer and process load.

MCB VS MCCB VS Industrial breaker

| Features | MCB | MCCB | Industrial Breaker |

|---|---|---|---|

| Typical Current Range | 0.5A – 125A | 100A – 2,500A | 100A – 6,300A (adjustable) |

| Voltage Rating | Up to 415 V AC | Up to 1,000 V AC | Up to 1,000 V AC or higher |

| Trip Settings | Fixed (non-adjustable) | Adjustable (thermal & magnetic) | Fully adjustable (via dials or electronic trip units) |

| Primary Use | Residential and light commercial loads | Industrial, commercial, and large feeders | Industrial systems with variable or critical loads |

| Protection Type | Overload & short circuit | Overload, short circuit, ground fault | Overload, short circuit, ground fault, coordination |

| Breaking Capacity | 6 kA – 15 kA | 25 kA – 100 kA | 25 kA – 150 kA (depending on design) |

| Size and Mounting | Compact DIN rail type | Larger, panel-mounted | Larger, panel-mounted with adjustable settings |

| Maintenance | Simple plug-and-play | Moderate (replaceable trip unit) | Requires calibration and periodic testing |

| Cost | Low | Moderate | High |

| Best Suited For | Homes, small offices, lighting circuits | Factories, panels, machinery circuits | Complex industrial systems requiring custom protection |

This article is a part of the Switchgear, where other articles related to switchgear are discussed in details.