Cable joint is a process of connecting two or more electrical cable for extending the length and form a continuous electrical circuit. The main purpose of cable joints is to maintain efficient electrical continuity along with good mechanical strength without affecting the insulation integrity across the cable’s connection. A proper cable joint ensures that current flows smoothly without resistance or current leakage preventing cable overheating and power loss. In medium and high voltage systems, the reliability of the joint is very critical to withstand the voltage stress, thermal stress and harsh environment. Poor joints can result in insulation breakdown, moisture ingress and even cable failure, making the joints very essential from the safety and performance point of view.

Table of Contents

Objective

Mechanical strength and Electrical continuity: The cable joint has to ensure that the connected cable must withstand the mechanical forces during operation (500-1500N) depending upon the cable size. Properly aligned cable conductors and strong connector maintain low electrical resistance which prevents over heating and voltage drops. Ideally the joint’s DC resistance should match with that of the cable but practically a 10% increase in the DC resistance is considered acceptable. The contact resistance at each connector must be below 10 µΩ.

Adequate insulation and moisture sealing: The cable joint’s insulation must restore the dielectric strength equivalent to that of the parent cable which is usually more than or equal to 20 KV / mm. Moisture resistance is achieved in the cable joints by the use of heat shrink or resin sealed sleeves and is tested for more than 10⁶ MΩ of insulation resistance. Proper sealing prevents moisture ingress, ensuring the joint successfully withstand 16 KV for 15 minutes without breakdown or partial discharge as per IEC 60502-1 for LV and MV cables.

Safe and long service life: The joint should easily withstand a continuous operating temperature of 70 °C and during a short-circuit 160 °C for 5 seconds without any insulation deterioration. Properly designed joints ensure a long service life of cables extending 25 years under normal operating conditions.

Classification of cable joint

Based on voltage level

Low voltage joints: These joints are used in the domestic and industrial electrical wiring, which provides safe electrical continuity and insulation for the low voltage circuits rated up to 1.1 KV. The cables are typically PVC insulated with cable accessories of PVC or resin compound tapes. This complies with IEEE 404-2020 and IEC 60502-1 for low voltage cableing.

Medium Voltage joints: These are designed for distribution circuit networks. These cable joints withstand a voltage stress up to 36 KV. It uses stress control tubing and semi conductive screen layers for maintaining the field uniformity. These joints also utilizes the heat shrink or cold shrink insulation system to maintain long term reliability in underground and outdoor cable installation.

High voltage joints: These joints are installed in power transmission networks, built to withstand high voltage and thermal stresses. It includes advanced stress grading, metallic shielding and oil or resin filled insulation in order to maintain proper dielectric strength, prevent partial discharge with reliable operation.

Based on cable type

PILC cable joint: The paper insulated lead covered cables are basically joined with lead sleeves and oil impregnated paper for restoring the insulation and prevent moisture ingress. These joints are durable for underground applications but requires skilled workmanship as PILC cables are heavy.

XLPE cables joint: These are designed for applications in XLPE cables specifically, utilizing stress control tubes, semi conductive layers and polymer insulation. These joints are lighter, provides easier installation and are capable of handling high operating temperatures and voltages.

PVC cable joint: These joints are used in domestic and industrial electrical circuits up to 1.1 KV. These joints use PVC or resin-based compounds for insulation and mechanical strength. These joints are simple and economic for permanent and temporary domestic electrical connection.

Types of Cable joint

Straight through joint: This type of joint is used to connect two ends of a cable in a straight line. It is commonly used for underground cable extension or for cable repairs. The core of the cable is connected by compression connectors or soldered ferrules, it is then insulated with paper or heat shrink sleeves. Layers of insulation tapes, lead sheath and PVC or bitumen outer sheath is applied for ensuring moisture sealing and mechanical strength.

Branch (T) joint: This joint is used for tapping in one cable from another without cutting the main cable entirely. In practice, the main cable is stripped and a branch connector or crimp lug is attached to the tap cable. The joint is then covered with insulating material, heat shrink sleeve and then covered with moulded or taped waterproof shell so that the continuity is maintained with no moisture ingress.

Transition Joint: This type of joint are used to connect different types of cable, commonly PILC and XLPE for system upgrades. The paper layers are carefully tapered for uniform field distribution and sealed with non-hygroscopic resin, while XLPE side uses stress control tube and epoxy resin kit to manage field stress. The metallic continuity bond maintains the sheath potential, while the outer resin or heat shrink housing ensures environmental protection.

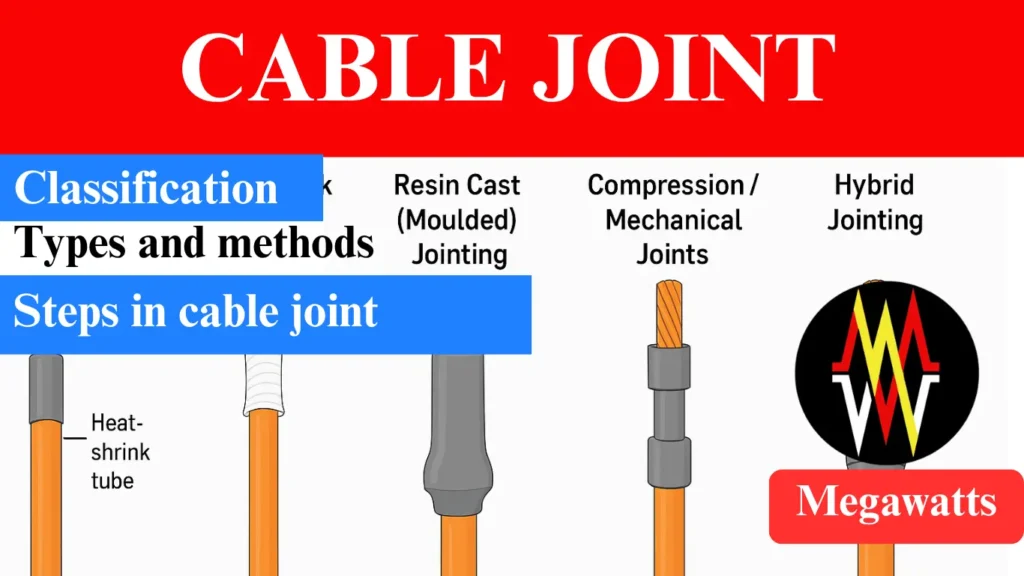

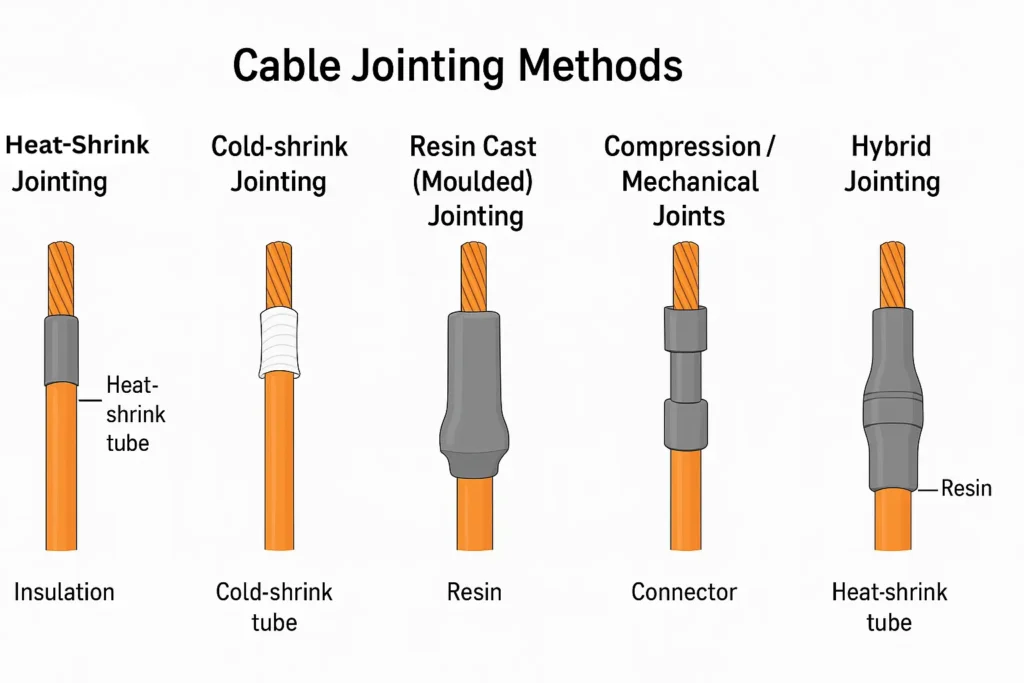

Methods of cable joints

Heat shrink joints: It uses heat shrinkable polymer sleeves that contacts on application of heat. The joint is first cleaned, crimped and insulated and covered with layers of semiconductive, insulation and outer heat shrink tubes. This method is usually applied for quick repairs and compact installations up to a voltage range of 33 KV.

Cold shrink joints: These are made of pre expanded silicone or ethylene propylene diene monomer (EPDM) rubber, which shrinks automatically when the inner spiral core is removed. It is ideal for indoor substation, oil plants or gas zones cable joints as it requires no heating. Clean, UV resistant and time saving cable assembly can be achieved in tighter spaces with the application of cold shrink joints.

Resin cast joints (Moulded): In this process of cable joints, cables are first positioned inside a plastic mould and ten epoxy or polyurethane resin is poured in to encase the joint. After curing of the casting, it forms a rigid, waterproof and impact resistant enclosure. Resin joint offers very good corrosion resistance and are ideally used in underground networks, mines and industrial plants. A proper mix and perfect curing time is essential to prevent air pocket formation.

Compression joints: In this process, copper or aluminium conductor are joined using crimp lugs or mechanical shear bolt connectors by the use of hydraulic crimping tools. It offers low contact resistance joints with high mechanical strength. These joints are widely used in 11 KV networks, transformer connections and temporary restoration works. The tightness and proper alignment is the key to avoid a joint failure in this case.

Hybrid Joints: It combines two jointing methods like resin cast with heat shrink outer sealing or mechanical compression joint with cold shrink insulation. These methods of joining cables are used in high voltage installation or where the environment is harsh, requiring extra protection from moisture, vibration or thermal stress.

| Method | Typical Voltage Range | Installation Ease | Relative Cost | Moisture Protection | Common Applications / Remarks |

| Heat Shrink Jointing | Up to 33 kV | Moderate (requires heating torch) | Medium | Excellent | Widely used in outdoor networks, quick field repairs, and distribution systems |

| Cold Shrink Jointing | Up to 36 kV | Easy (no flame required) | Slightly high | Very good | Indoor substations, oil/gas zones, confined areas |

| Resin Cast (Moulded) | Up to 11 kV (some designs up to 36 kV) | Moderate (mixing and curing needed) | Medium to high | Excellent (fully sealed) | Underground cables, industrial environments, water-prone zones |

| Compression / Mechanical | Up to 33 kV | Easy (needs crimping tools) | Low | Good | Temporary connections, terminations, and maintenance work |

| Hybrid Jointing | Up to 66 kV and above | Complex (multi-step) | High | Superior | High-voltage, outdoor, or corrosive environments; long-term reliability applications |

Steps of cable jointing

Preparation of cable ends: Carefully cut or strip the cable ends to specified dimension, clean the conductor with lint free cloth and solvent to remove grease, dirt and moisture.

Jointing of the conductor: Align the conductors properly and connect them using the compression lugs, crimping dies or soldering depending on the type of joints. Also ensure proper mechanical tightening and electrical resistance free contact without damaging conductor strands.

Application of insulation and shielding layer: The insulation is rebuild using cold shrink or heat shrink tubes with required stress control tapes. By properly restoring the metallic screening, earth continuity is checked for uniform field distribution.

Sealing with jointing material: By the application of heat shrink sleeves or resin compound, sealing of the outer sheath is achieved for protection against moisture ingress and contaminant. By covering properly, the joint integrity is maintained through proper curing.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.