An ACSR conductor (Aluminium Conductor Steel Reinforced) is a composite, stranded conductor which finds wide application in the overhead transmission line. The outer section of ACSR conductor is basically made of stranded aluminium wires which provides excellent electrical conductivity with the steel core enhancing the overall mechanical strength for efficient power transmission over longer distance with minimal sag exhibiting higher tensile strength.

By the integration of aluminium for enhancing flow of current and galvanized steel for tensile strength, the balance between the mechanical endurance and electrical efficiency is achieved. It is because of the design of the conductor, it supports longer spans while providing stability against wind, ice and temperature variation for a reliable power transmission.

Table of Contents

Construction

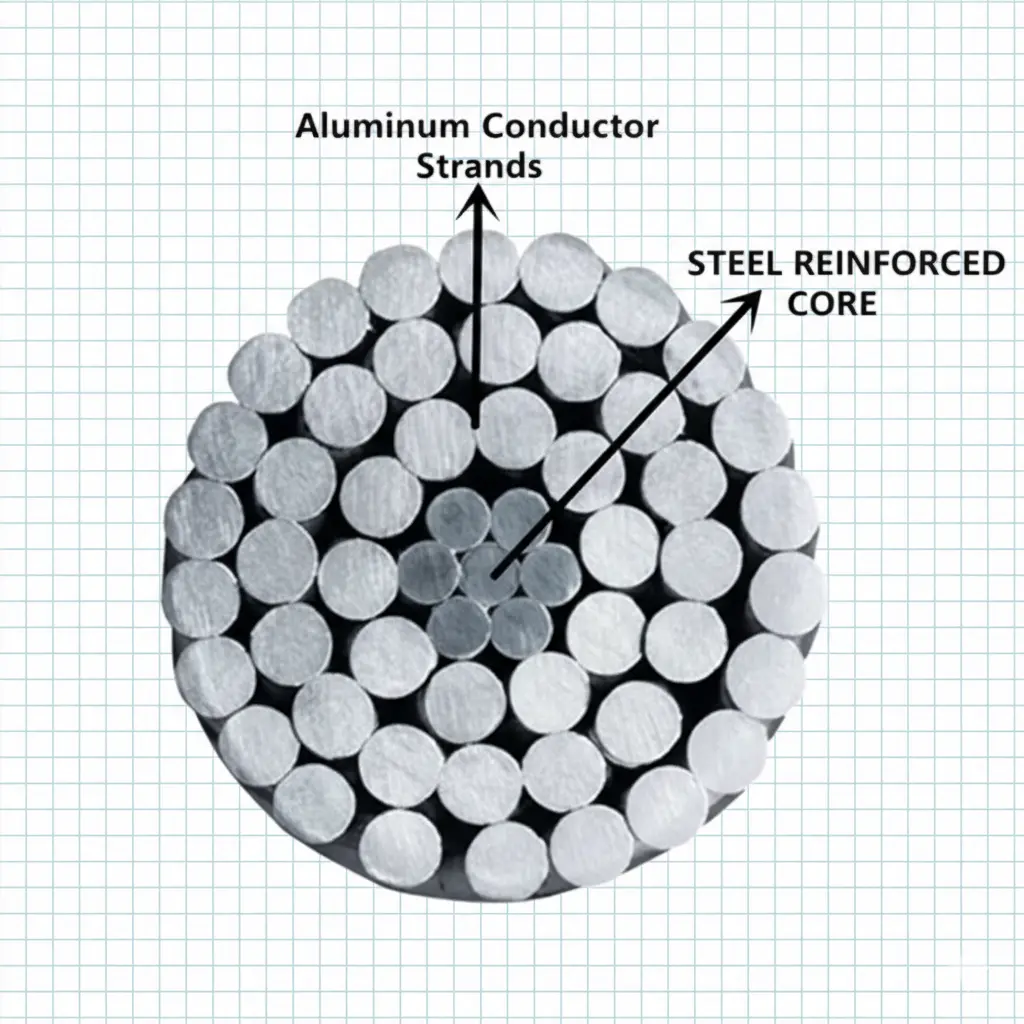

The ACSR conductor wire is precisely engineered combination of mechanical strength and electrical efficiency. The ACSR wire is basically designed for the overhead power transmission and distribution system. The ACSR conductor wire has a concentric layers of hard drawn aluminium strands helically wound around galvanized steel core for higher tensile strength and reliable electrical conductivity.

The steel core is typically a galvanized carbon steel or high strength zinc coated steel, which serves as structural backbone of the conductor as the core supports the mechanical load of the line, that allows the ACSR conductor to span long distance between transmission towers with manageable sag. The steel core of the ACSR conductor can be single or stranded, depending up on the size of the conductor and requirement of strength.

The steel core is surrounded by one or more layers of electrical grade hard drawn aluminium wire. The aluminium wires are laid helically in opposite direction in successive layers which reduces the stress caused due to torsion and also maintains the circular geometry. The aluminium envelope of the conductor is comparatively of low density and carries the maximum electric current because of excellent conductivity, while the steel core handles the mechanical load.

Various sizes of the ACSR conductor is available which is a function of the aluminium to steel cross sectional area ratio, depends up on the desired conductivity and tensile strength. Common configuration of the ACSR wire are designated by animal names like Moose, Zebra, Panther, etc, each referring to a specific aluminium and steel strand numbers and diameters.

Corrosion resistant version of the ACSR conductor uses a steel core, coated with aluminium clad or 5% zinc aluminium misch metal alloy (Zn-5AL-MM) coating for enhanced longevity. This allows the conductor to have a better performance under high mechanical stress and withstand high temperature variation and environmental exposure making it a suitable choice for high voltage transmission circuits.

Properties of ACSR conductors

High Tensile strength: The steel core of the ACSR wire usually has a tensile strength of 1100-1800 MPa, which makes the ACSR conductor to withstand high mechanical tension. The typical breaking strength of the ACSR conductor is in the range of 40 KN (Weasel) to 250KN (Zebra). This makes sure that the conductor sag is minimum even for span over 400 meters, which improves the reliability of the transmission line under different wind and ice loading conditions.

Lightweight: ACSR conductors usually have the advantage of being lightweight with an average weight of 700-1400 Kg/Km, despite of the steel reinforcement. This is because of the less density of the aluminium, which is 2.70 g/cm3. This greatly reduces the mass of the ACSR conductor compared to copper conductors. The lightweight feature aids in the stringing of the transmission line, reduces the tower loading and allows longer span while maintaining the electrical and mechanical performance.

Good conductivity: The aluminium strands has a electrical conductivity of around 61% of IACS (International Annealed Copper Stranded) conductor, enabling current carrying capacity from 200A (Small Sized) to 1600 A approximately (large sized) conductors. The low electrical resistance of around 0.05 to 0.25 Ω/km helps in achieving minimal power loss during high voltage transmission.

Corrosion Resistance: The core of the ACSR conductor is galvanized with a Zinc coating of 250 to 600 g/m2, which offers brilliant protection against corrosion. For application in harsh environment, aluminium clad steel or Zn-5%-MM alloy core is used which extends the service life of the ACSR wires beyond 40 years. The oxidation, salts and industrial pollution is resisted by the anti corrosive materials ensuring the long term durability and safety.

Thermal stability: ACSR conductors has a continuous operation temperature range of 75-90 degree Celsius with a overloading capacity of 120 degree Celsius for short duration. The coefficient of linear expansion of the ACSR conductors is around 19*10-6 /degree Celsius, which gives a predictable sag tension behaviour of the ACSR wire. This thermal stability offers consistent performance under the fluctuating load and it prevents the mechanical fatigue.

Types of ACSR conductors

Standard ACSR conductor: These are composed of concentric aluminium strands surrounding the steel core, offering excellent strength to weight ratio of around 100-300 N-m / Kg.

ACSR Conductor with galvanised steel core: It features a zinc coated steel core, which provides a high mechanical support and corrosion protection and is ideal for medium voltage and standard environmental application.

ACSR conductor wire with aluminium clad steel: These conductor uses a aluminium coated steel core for superior corrosion resistance, which is suitable for coastal, humid and industrial regions with high pollution levels.

Compact ACSR conductor: These type of ACSR wires are made with reduced outer diameter and tighter strandings, which reduces the wind loading, improves the amperage of the conductor and reduces the electromagnetic interference.

Long span ACSR conductor: These conductors are designed for extra high voltage transmission lines which supports long spans of about 600 meters, with enhanced tensile strength and can withstand high mechanical stress with reduced sagging.

Advantages and Limitations of ACSR wires

| Advantages | Limitation |

| Good balance between strength and conductivity. | Limited conductivity as Steel has low conductivity. |

| Cost effective and long lasting compared to copper. | Chances of galvanic corrosion between aluminium and steel is high. |

| Easy installation and maintenance. | Under high temperature operation, Sag of the line increases. |

| Offers high stability under heavy wind and ice loadings. | Fatigue at clamps and joints as ACSR wires are prone to aeolian vibrations and galloping. |

Various ACSR conductor sizes

| Conductor Name | Aluminium Strands / Steel Strands | Nominal Area (mm²) | DC Resistance at 20°C (Ω/km) | Ampacity at 50°C (A) | Ampacity at 75°C (A) | IS Reference | ASTM Reference |

| Weasel | 6/1 | 30.58 | 0.967 | 140 | 180 | IS:398 (Part 2) | ASTM B232 336 |

| Rabbit | 6/1 | 50.00 | 0.579 | 190 | 240 | IS:398 (Part 2) | ASTM B232 336 |

| Raccoon | 6/1 | 80.00 | 0.353 | 260 | 320 | IS:398 (Part 2) | ASTM B232 397 |

| Dog | 6/1 | 100.00 | 0.276 | 290 | 370 | IS:398 (Part 2) | ASTM B232 477 |

| Wolf | 6/1 | 125.00 | 0.221 | 330 | 410 | IS:398 (Part 2) | ASTM B232 556 |

| Panther | 30/7 | 200.00 | 0.139 | 450 | 540 | IS:398 (Part 2) | ASTM B232 636 |

| Zebra | 54/7 | 300.00 | 0.093 | 570 | 680 | IS:398 (Part 2) | ASTM B232 795 |

| Moose | 54/7 | 410.00 | 0.068 | 710 | 850 | IS:398 (Part 2) | ASTM B232 954 |

| Drake | 26/7 | 430.00 | 0.064 | 750 | 890 | IS:398 (Part 2) | ASTM B232 795 |

| Rail | 54/7 | 520.00 | 0.055 | 880 | 1000 | IS:398 (Part 2) | ASTM B232 1113 |

| Bersimis | 54/7 | 620.00 | 0.047 | 950 | 1120 | IS:398 (Part 2) | ASTM B232 1272 |

| Lapwing | 54/7 | 800.00 | 0.038 | 1100 | 1300 | IS:398 (Part 2) | ASTM B232 1350 |

| Falcon | 54/7 | 1000.00 | 0.031 | 1250 | 1450 | IS:398 (Part 2) | ASTM B232 1590 |

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.