AAAC conductor (All Aluminium Alloy Conductor) is basically an electrical conductor, which is entirely made up of an aluminium-magnesium-silicon (Al-Mg-Si) alloy. The Aluminium provides excellent electrical conductivity of around 53% of IACS (International Annealed Copper Standard) and low weight because of its low density, making it efficient for power transmission over longer distance. Magnesium adds to the mechanical strength and hardness of the alloy without raising its weight much.

While Silicon enhances the corrosion resistance properties and also helps in precipitation hardening increasing the durability of the conductor. It is widely used in overhead transmission and distribution lines up to 800KV voltage level as it offers superior balance between conductivity, strength and corrosion resistance. The tensile strength of AAAC conductor is in the range of 250 to 300 MPa and being almost 10% lighter than the ACSR conductors, AAAC conductor allows longer span of transmission tower with low sag for same current carrying capacity.

Table of Contents

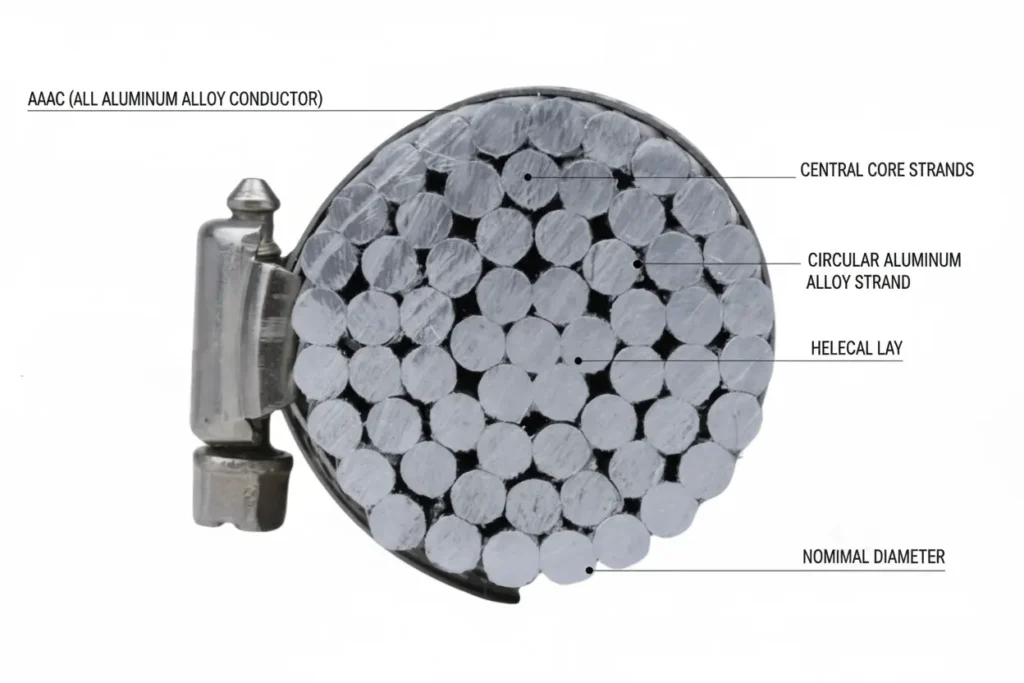

Construction of AAAC Conductor

The construction of AAAC (All Aluminium Alloy Conductor) incorporates the use of stranded aluminium alloy wires for enhanced strength, conductivity and flexibility. Unlike the ACSR conductors, AAAC conductors have no steel core, hence the entire cross section of the conductor is subjected to mechanical loading and electrical conduction. This makes the AAAC conductor, strong and also light weight making it suitable for medium to high voltage overhead transmission lines.

The preferred alloy for the construction of AAAC conductor is 6201-T81 which is a heat-treated Al-Mg-Si (Aluminium-Magnesium-Silicon) alloy, with a tensile strength of around 300 MPa, that is higher than pure aluminium conductors. This alloy as specified in the ASTM B399 or IEC 61089 standard is chosen because of the reproducible electrical conductivity of 53% of IACS (approximately). This makes the AAAC conductor to carry large current with minimal losses and good mechanical performance.

AAAC conductors are made into concentric lay, helically stranded aluminium wires. The central strands of the conductor acts as the core around which successive layers of aluminium alloyed strands are wound helically in opposite direction, which maintains the balance and minimizes the torsion as well. Common configuration includes 7, 19, 37, 61, or 91 strands, while it largely depends upon the desired mechanical capability of the conductor. IEC 61089 lists AAAC conductors with cross-section starting from 16mm2 to 1120mm2.

The surface of the conductor is smooth and highly corrosion resistant, allowing for safe application in coastal, and industrial areas with high pollution levels, where other conductor’s performance will get severely affected. Also the absence of steel core in the case of AAAC conductor eliminates the risk of galvanic corrosion.

The uniform composition of the conductor gives better sag characteristics, less weight per kilometer and enhanced flexibility during installation and the construction of this conductor allows it to be durable, and efficient with maintenance free performance for overhead transmission line.

Properties

Electrical: The conductor has excellent electrical conductivity of around 53% of IACS along with a resistivity of around 0.0328 Ω·mm²/m at 20°C. The temperature coefficient of the resistance of the conductor is 0.004/°C, which ensures predictable sag performance under varying load. The current carrying capacity of this conductor is 10-15% higher than that of ACSR conductor as the entire cross-section conducts current. Because of the smooth surface of the conductor, the AAAC has a very low corona loss with less radio interference.

Mechanical: The conductor can operate efficiently up to 90 °C with full ampacity with minimal sag or degradation. It can also carry temporary overload current up to 120 °C but only for a short duration of time. The tensile strength of the conductor is around 300 MPa with a modulus of elasticity of around 69 GPa which is higher than pure aluminium, it provides lower sag and help maintain a safe clearance. This modulus of elasticity also helps the conductor with less deformation or creep at high wind or ice loading.

The density of 2.7 g/cm³ makes the conductor lighter and improves the strength to weight ratio, which makes longer tower spans possible. The coefficient of linear expansion of this conductor is 23 × 10⁻⁶/°C which aids in the thermal flexibility as the conductor can expand with temperature and absorb the thermal stress instead of snapping. The melting point of the conductor material is much higher at around 640 °C. As the steel core is absent, it offers a superior corrosion resistance and uniform mechanical performance.

Application

AAAC ( All Aluminium Alloy conductor) is widely used in overhead transmission and distribution line ranging from 11 to 800 KV. It’s high strength to weight ratio and excellent corrosion resistance makes it an ideal choice for coastal, humid and industrial areas where other conductor’s performance will deteriorate. This conductor is used in urban and rural electrification for river or valley crossings because of its low sag and light weight. These are also used in high voltage substation and renewable energy sites for its maintenance free performance and longer service life in every environmental conditions.

Advantages

- The conductor has high tensile strength providing better mechanical performance.

- The conductor is light weight, which allows longer tower spans and easier stringing.

- The conductor offers good conductivity, ensuring efficient current flow.

- No steel core makes sure of no galvanic corrosion, which improves uniformity.

- The conductor offers higher operating temperatures up to 90 degree for continuous operation.

- The conductor offers low sag because of better strength to weight ratio.

- It offers low maintenance with limited inspection requirements.

Limitations

- The material of the conductor is expensive.

- The use of this conductor is limited in very large span transmission lines because of low ultimate strength.

- The specific tensile strength is less making the use limited in high wind and ice prone areas.

- The sag for thermal expansion is slightly more under high temperature operations.

- Surface damage during installation can make the conductor prone to corrosion.

Various AAAC conductors with different trade names

| Trade Name | Nominal Aluminium Area (mm²) | No. of Strands (Al) | Typical Current Rating (A @45°C) | DC Resistance at 20°C (Ω/km) |

| Mole | 15.82 | 7 | 65 | 1.91 |

| Squirrel | 22.58 | 7 | 105 | 1.34 |

| Weasel | 34.37 | 7 | 155 | 0.88 |

| Rabbit | 55.42 | 7 | 210 | 0.55 |

| Racoon | 80.26 | 7 | 275 | 0.38 |

| Dog | 100.00 | 7 | 325 | 0.32 |

| Wolf | 125.00 | 7 | 380 | 0.26 |

| Panther | 232.00 | 19 | 520 | 0.142 |

| Lynx | 150.00 | 7 | 420 | 0.22 |

| Coyote | 200.00 | 19 | 470 | 0.165 |

| Zebra | 465.00 | 37 | 800 | 0.071 |

| Moose | 520.00 | 37 | 850 | 0.065 |

| Bersimis | 767.00 | 61 | 1000 | 0.044 |

| Greeley | 927.00 | 61 | 1080 | 0.037 |

| Alliance | 362.00 | 37 | 395 | 0.088 |

Actual ampacity may vary with installation condition, and wind speed.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.