Substation SCADA (Supervisory Control and Data Acquisition) is basically a system of certain hardware and software through which monitoring, analysis, and control of a power system can be achieved remotely. The data is acquired from the field equipment, transmitted to a central unit utilizing a communication network, which is then displayed in the Human Machine Interface (HMI) of the SCADA so that the operator can analyse the system and take action remotely.

Table of Contents

Without the SCADA, the operation of the substation will become complex, and switching of equipment will need manual intervention; real-time monitoring of substation data will not be possible, increasing overloading risks. Historical data logging will not be present, and hence any prediction of trends will not be possible, which will hamper the predictive maintenance. More manpower will be needed to carry out work manually, which will add to operational expenditure.

Key components of SCADA

Master terminal unit (MTU): The master terminal unit in SCADA is the central unit in the system, which collects the data from various IEDs (Intelligent Electronic Device) in the substation, analyzes, and stores the data for future trend analysis and forecasting. The master terminal unit is capable of sending open/close signals to circuit breakers, isolators, and earthswitches. It is also capable of changing taps and operating a standby Diesel gen-set. The master terminal unit communicates with various IEDs over the IEC 61850 protocol and interfaces the entire substation in the Human Machine Interface HMI, so that the operators can analyse and control the power system.

Remote terminal unit (RTU): The remote terminal unit is a microprocessor-based device that translates the electrical parameters from the field devices, like current transformer, potential transformer, and Circuit breaker, to the master terminal unit of the SCADA. It collects the data from the switchyard devices, meters, and relays, translates it, and transmits it to the control center or master terminal unit for display in the HMI of the SCADA in real-time. For example, the breaker status (open/close), bus voltage, phase currents, incoming and outgoing powers for each feeder, etc.

The remote terminal unit also receives the operator’s command from the HMI of the SCADA via the master terminal unit and executes the command in the various field devices. It also records the system disturbances with a precise time stamp. The RTU basically acts as the messenger between the MTU and the field devices, receiving data and executing commands.

Programmable logic controller (PLC): A Programmable logic controller in a substation is used for the local automation and control within the substation SCADA system. The circuit breaker interlocking logics, the transformer’s tap changer process, the transformer’s cooling fan and pump’s operation, the fire protection system, etc, are automated and executed with the help of PLC. The PLC is capable of collecting signals from the OTI, WTI sensors and process them, giving real-time values to the substation SCADA via the IEC 61850 communication protocol.

For example, overheat is detected in the transformer by the sensors, the PLC receives the signal and compares it to the set threshold, and if high, it starts the cooling fans and pumps. In the process, it also communicates with the substation SCADA for the operator’s awareness. PLC’s response time is very fast in milliseconds, faster than RTUs. Also, it can be configured and used as an RTU for local substation SCADA communication. PLCs can be used for integrating old legacy devices like transformers and breakers without communication ports into the substation SCADA.

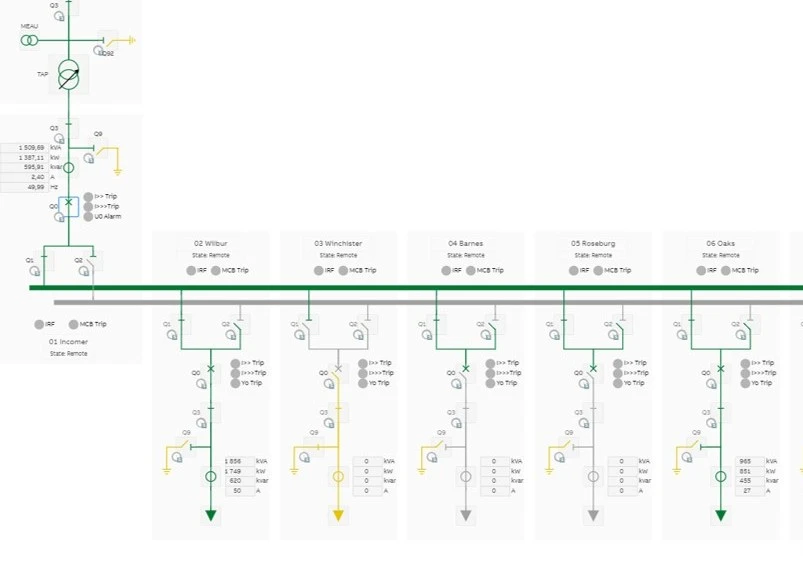

Human Machine Interface (HMI): The HMI of a substation SCADA is a responsive graphical representation-based software program, which allows the operator to monitor and interact with the various field equipment of the substation remotely. The HMI provides a single-line diagram representation of the substation along with real-time status of various devices and electrical parameters like voltage, current, load, etc.

The HMI allows the operator to interact with various substation devices and control them remotely, like the operation of the circuit breaker and isolator. HMI can also display the historical data logged and show the past event logs. It can raise visual and audio alarms for any abnormal condition in the power system, thus alerting the operator. HMI is the operator’s dashboard, or a visual representation of the substation SCADA, which helps in substation management.

Communication System: It refers to networks and technology used as a transmission link for data and control signals between the field devices and the substation SCADA. Nowadays, optical fiber is used for the transmission of data as it remains unaffected by electromagnetic interference. Also, Ethernet (LAN/WAN) is used as a media channel for data transmission in modern substations. Network devices like Ethernet switches and routers are taken in use, gateways are required for translation of Modbus to IEC 61850 protocol, and multiplexers for combining multiple signals into a single channel.

Application of substation SCADA

Remote monitoring: The Operator can remotely monitor the status of various substation equipment, power flow parameters like voltage, current, power active and reactive, etc, directly from the control room.

Remote control: The operator can remotely control various substation equipment, like the operation of circuit breakers, isolators, transformer tap changers, and capacitor banks, directly from the control room with little to no manual intervention, ensuring safety.

Data logging: It can store data, events, alarms, and record faults, which can be used for analysis, predictive maintenance of the substation, and also optimise the load distribution.

Alarm and Event management: The substation SCADA is capable of raising an alarm for any abnormal power system condition, alerting the operator for prompt action.

Advantages

Less manual intervention: With the substation SCADA application, manual intervention for checking equipment status, which was previously mandatory, has been cut short, and hence the utility can run with less manpower, cutting the operational expenditure.

Enhanced reliability and efficiency: Substation SCADA can maintain stable operation of the substation by monitoring load, voltage, and current. Real-time monitoring helps prevent the overloading and overstressing of the equipment, improving the reliability and efficiency.

Improved safety: High voltage substations are a risky environment. Application of substation SCADA minimizes the exposure to high voltage live equipment as these can be monitored and controlled remotely, minimizing the risk and improving safety.

Better decision making: With the application of substation SCADA, operators and engineers have easy access to real-time data and it helps to detect anomalies and take informed decisions.

Limitations

Cybersecurity risk: Since the communication channels are Ethernet-based, hackers can access the system with risks of malware/ransomware attacks. The consequence of this can be severe, like equipment damage, power outage, and grid instability.

High cost of installation and maintenance: It involves advanced equipment like IEDs, RTUs, HMI, server; the installation cost will be very high, and also the maintenance requires specialized tools and personnel, which is also a costly affair.

Dependency on networks: The operation of SCADA depends on a robust network with low latency and uninterrupted communication between the control room and switchyard equipment. Hence, any delay or congestion in the network can cause the performance of the system to drop and affect the protection and operation. Therefore, redundant communication networks are necessary for increasing reliability.

This article is a part of the page Substation Guide.