The Rankine Cycle comprises of 4 thermodynamic processes on which the steam engine or turbine is based to convert the heat energy into mechanical work. It is also the ideal vapour cycle which is used for comparing the performance of various power generating plants running on steam.

Table of Contents

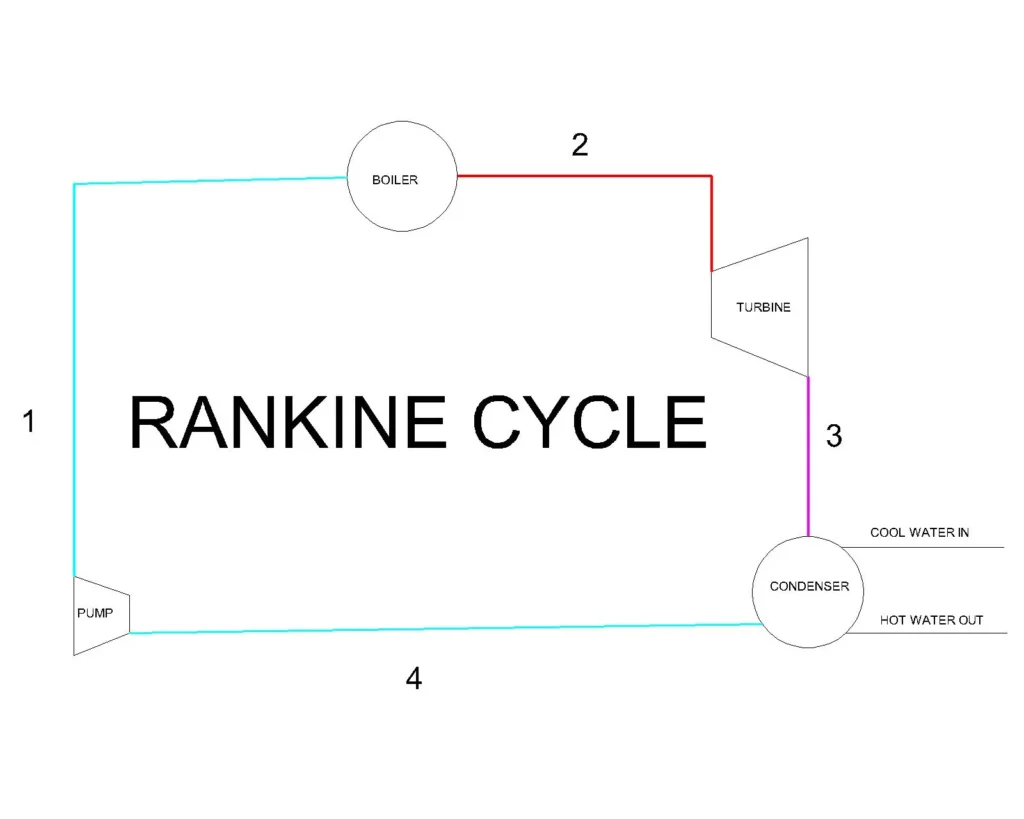

Basic components of Rankine cycle

Boiler: A boiler is a control volume where heat at constant pressure is added to convert the water into steam.

Turbine: In a steam turbine, the high-pressure steam is expanded isentropically so that mechanical work is obtained. In the process, the steam loses the pressure and temperature.

Condenser: At the condenser, the low-pressure steam from the turbine condenses back into water at a constant pressure and temperature. In the process of condensing, the steam loses its temperature to the cooling medium.

Pump: The condensed water is pressurized at the boiler pressure and pumped back into the boiler.

Processes involved in Rankine cycle:

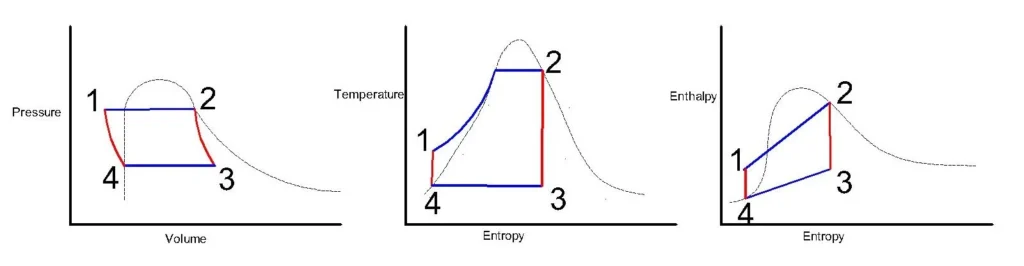

During process 1-2, the water in the boiler is converted to steam at constant pressure, and the heat addition is done at an approximately constant temperature unless the steam is superheated. This means the temperature and pressure of the dry saturated steam at point 2 is same as the temperature and pressure at point 1.

Therefore, the heat added during 1-2 is the latent heat of vapourisation corresponding to pressure p1 and p2.

During process 2-3, the dry saturated steam expands isentropically in the steam turbine or engine, losing both temperature and pressure with a dryness fraction less than unity. The entropy remains constant during the process as no heat is supplied or rejected.

During the process 3-4, the wet steam, that is the steam with a dryness fraction less than unity, is condensed at constant pressure, and as the latent heat is rejected for conversion of wet steam to water, the process becomes approximately isothermal. The temperature and pressure at point 3 is the same as the temperature and pressure at point 4. The rejected heat during the process is equal to the multiplication value of the dryness fraction and enthalpy at point 3.

During process 4-1, the water is pumped back to the boiler in an isentropic process. Since water is incompressible, there is very little change in the specific volume of water during the process.

Considering 1kg of water at pressure p1 and temperature T1,

Applying the steady flow energy equation to control volume of the boiler,

h1 + q1 = h2 or Q1 = h2 – h1

Applying a steady flow energy equation to control volume of the turbine,

h2 = WT + h3 or WT = h2 – h3

Applying steady flow energy equation to condenser, h3 = Q2 + h2 or Q2 = h3 – h2

Applying steady flow energy equation to pump, h4 + WP = h1 or WP = h1 – h4

Therefore, efficiency of the Rankine cycle is

η = Wnet / Heat supplied Q1

η = WT-WP / Q1

η = (h2 – h3) – (h1 – h4) / h2 – h1

During the process 4-1, the isentropic process and change in specific volume is minimal as stated earlier,

Mathematically, Tds = dh – vdp. Since, change in entropy ds is equal to 0, therefore

dh = vdp or h1 – h4 = v4 (p1 – p4).

Also, the pump work is very small compared to the work output of the turbine, hence it is often neglected when the boiler pressure is low.

Therefore, the efficiency of rankine cycle becomes, η = (h2 – h3) / h2 – h1.

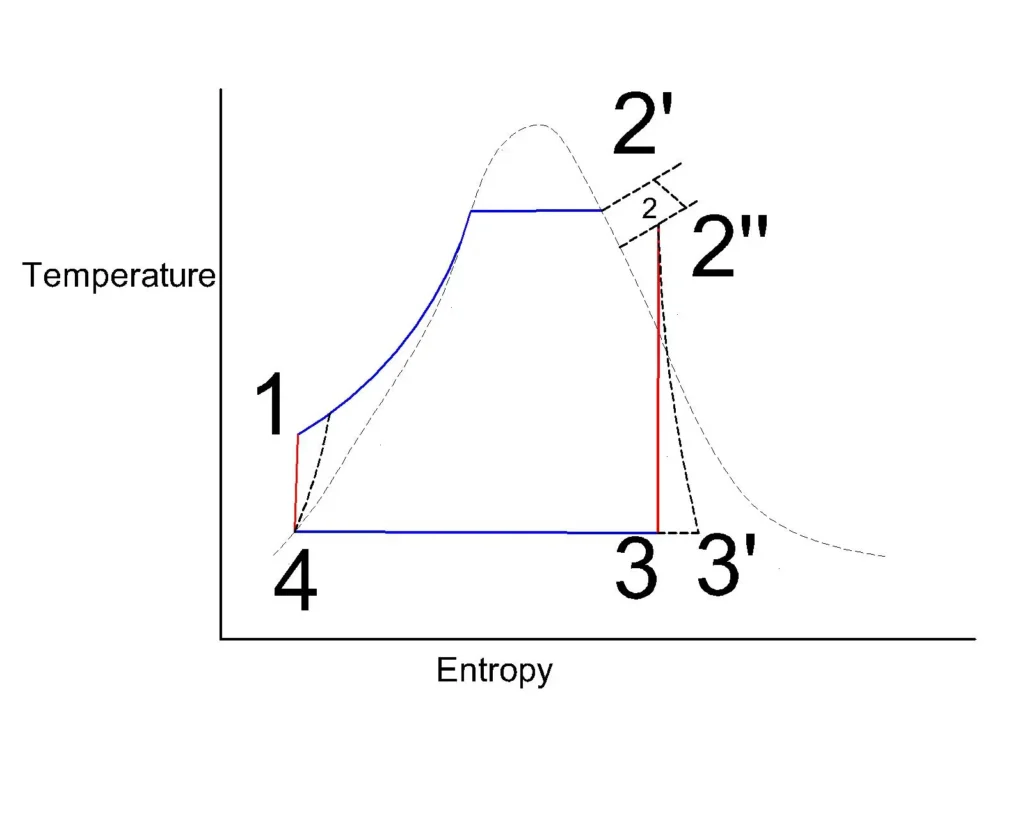

Losses in Actual Rankine Cycle

Pressure loss in pipe: Due to bends and frictions, pressure is lost in the pipes where steam leaves the boiler drum to enter the turbine. 2′-2 represents steam leaving boiler and entering turbine. 2′-2” represents frictional losses, 2”-2 represents heat lost constant pressure to the surroundings via the pipes before the steam enters the turbine. Similar pressure losses are observed in the case of the pipes between the pump and the boiler, which essentially increases the pump work in the actual scenario as the pump has to now deliver the water at more pressure than the steam pressure leaving the boiler.

Turbine losses: The frictional losses and heat loss to the surrounding affect the turbine efficiency also it is to be considered that the actual expansion of steam in the real turbine is neither reversible nor isentropic. Therefore the work output of the turbine is less than the ideal case.

Pump losses: The losses associated with the pump are due to the fluid friction similar to the turbine but in the case of the pump the heat loss is negligible.

Condenser losses: Condenser losses include the pressure loss and cooling of condensate below the saturation temperature also called subcooling.

Reference:

- Basic and applied thermodynamics by PK Nag

- A text book of Thermal engineering by RS khurmi and JK gupta