KNEE POINT TEMPERATURE

The temperature at which the envelope of a conductor becomes mechanically unloaded is called knee point temperature. When the temperature of a composite conductor is increased, the aluminium (or aluminium alloy) envelope wires undergoes more expansion than the core does. This expansion results in reduction of tensile load on the envelope.

Table of Contents

With rise in temperature, there will be gradual shifting of load from the envelope to the core, ultimately, resulting in the core being subjected to the entire mechanical load.

The temperature at which the envelope of the conductor carries no mechanical load, and the conductor being supported only by its core. This temperature is called Knee Point temperature.

Below the knee point temperature, the sag-tension equation of a conductor is related to the entire conductor but above this point, sag-tension of the conductor depends upon the core only, as the core carries all the load beyond the knee point.

In High-performance conductors, since the envelope has a higher coefficient of thermal expansion compared to core, the maximum sag of the conductor is therefore a function of the thermal expansion of the core only.

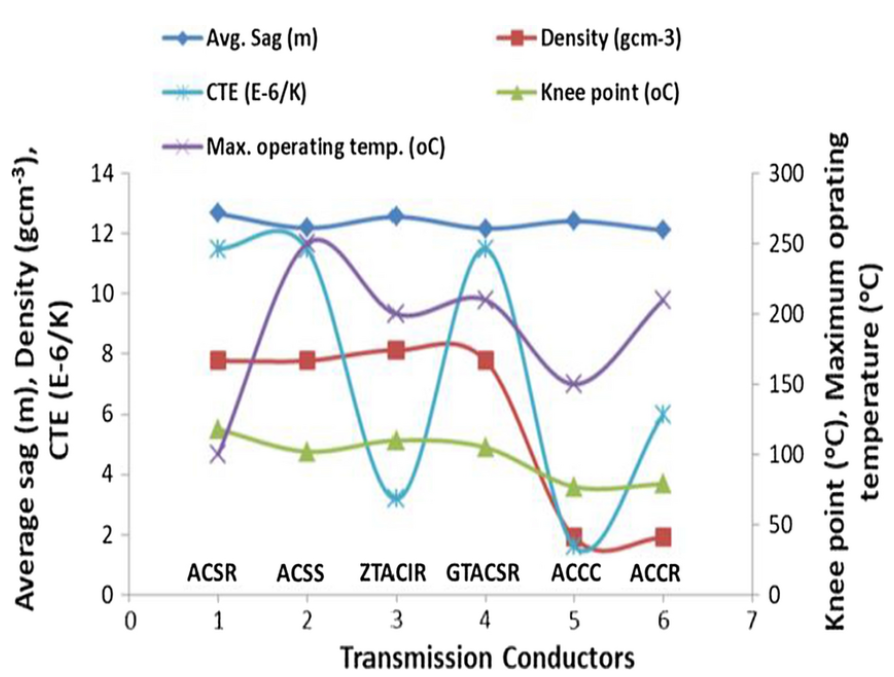

The knee point temperature is not equal but varies from type to type of conductors. It majorly depends on difference of coefficient of thermal expansion between envelope and core of the conductor. The knee point temperature also depends upon the installation of the conductor, prestressing of conductors can reduce the knee point more effectively, while the best results can be expected for conductors having envelopes of annealed aluminum.

The knee-point temperature also depends upon factors like length of span, initial tension of conductors, ruling conditions, and conductor properties like coefficient of thermal expansion, modulus of elasticity, etc.

Creep of the conductor is the result of plastic deformation of the conductor from tensile stress and elevated temperature. It primarily effects the envelope of the conductor and results in total unloading of the mechanical load. Therefore the knee point of the conductor also goes down with time because of the creep.

Therefore, for reaping the benefits of low expansion core, the rated temperature of the conductor has to be above the knee point temperature.

FACTORS AFFECTING THE KNEE POINT

Conductor are made from different materials having varied physical properties and knee point temperatures due to varied thermal endurances. As alloying is a major process by which electrical grade conductors are made, the knee point temperature becomes function of chemical composition of the alloy. Grain structures and stresses from initial tensioning of the envelope can affect the knee point of the conductor, however the heat treatment process can induce effective changes.

GRAPH OF KNEE POINT TEMPERATURE VS SAG

If the knee point of a conductor is low, then temperature of the conductor can raise higher before the maximum limiting sag of the conductor is breached. This gap from knee point to maximum sag temperature greatly effects the current carrying capability of a conductor. The more this gap will be, the more will be the current carrying capacity.

Based on the sag limit of the line, sag temperature profile is designed. With lower values of knee point, the thermal performance of the conductor increases.

Knee point is the point in the sag temperature curve at which the slope of the sag and temperature changes. The lower the knee point slope is, better sag temperature effect will be seen at the core. Thus, the use of a low thermally expandable core in the conductor will result in higher operating temperature limits and low sag.

CONCLUSION

It may therefore be understood from above that at the knee point temperature the core will be under tension for which it is specifically designed. If the line is operated below the knee point temperature of the conductor, there will be mechanical loading in the envelope of the conductor and it may cause damage to the envelope if usage is prolonged at or below the knee point temperature.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.