CONDUCTOR SIZING WITH IEEE-605

We have already discussed the busbar and the conductors in the previous articles. Now the essential part is to know how the conductor sizing is done for the main busbar of any substation. To explain this, we shall take the example of a 132KV substation with a 50MVA transformer capacity.

Table of Contents

For the calculation, we will follow the IEEE-605 standard for conductor sizing.

INPUT PARAMETERS:

Highest system voltage: 145 KV

Short circuit current, I: 31500 Amp

Duration of fault: 1 s

System frequency: 50 Hz

The initial temperature of the busbar before the short circuit, Ti : 85 degrees Celsius.

The final temperature of the busbar after short-circuit, Tf: 200 degrees Celsius.

FROM SHORT CIRCUIT CURRENT CALCULATION

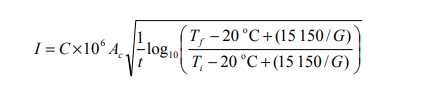

The above formula is only for Al-based conductors.

Where I is the short circuit current,

Ti is the initial temperature,

Tf is the final temperature, and G is the conductivity of IACS in percentage.

here G is taken as 40% of IACS

Therefore, Amin = (31500* √1) / (144000*√(log((200-20+(15150/40))/(85-20+(15150/40))))

= 0.069 in2 = 44.65 mm2

CONTINUOUS CURRENT CARRYING CAPACITY

Maximum demand at 132KV level = 50MVA

Required continuous current carrying capacity for the line = 50*106 / (√3 * 132000 *1)

= 218.69 A

Design margin of conductor @ 80% = 218.69 / 0.8 = 273.36A

Therefore, from the short circuit calculation and the continuous current carrying capacity, the minimum cross-sectional area of the conductor can be confirmed from the conductor manufacturer’s catalog. The selected conductor is hence ACSR Panther.

It may be noted that with the increase in temperature, the current carrying capacity of conductors decreases. Hence, in addition to design margin, and to take into account any future expansion plans, additional margins may be taken in the selection of conductors.

CONDUCTOR SIZING BASED ON IEC-865-1

INPUT PARAMETERS:

Highest system voltage: 245 KV

Short circuit current: 40000 Amp

Duration of fault: 1 s

System frequency: 50 Hz

The initial temperature of the busbar before short-circuit, ϴb: 75 degrees Celsius.

The final temperature of the busbar after short-circuit, ϴe: 200 degrees Celsius.

Selected conductor ACSR Moose, Area: 597mm2

Therefore, the rated short-time withstand current density for 1 sec, Sthr (IEC 865-1)

Sthr = K / √Tkr (A/m2)

Where K is the factor for calculating Sthr

Where c is the specific heat in J/kg ° C,

ρ is the mass density in kg/m3

K20 is the conductivity in 1/ Ω-m.

α20 is the coefficient of resistance at 20° C.

Tkr is the rated short time.

Therefore, For ACSR conductors,

we have, K20 = 3.48 * 107 / Ω-m.

α20 = .004 /° C

c = 910 J/kg ° C

ρ = 2700 kg/m3

Therefore, K = 85685784.92 A/m2

Sthr = 85685784.92 / √1 = 85685784.92 A/m2

= 85.68 A/mm2

Hence the short-time withstanding rating for moose ACSR = Sthr * Area of the conductor

= 85.68 * 597 = 51154.54 A

Therefore, the short-time rating of ACSR moose is greater than the required short circuit rating at 220 KV level which is 40000 A. Hence, the selected conductor is safe.

CHECK FOR MAXIMUM CURRENT CARRYING CAPACITY

Continuous current rating of single moose at 75° C from conductor catalog = 836 Amps.

The current carrying capacity of twin moose ACSR = 1672 Amps.

Full load current on 220KV side of 150 MVA Trafo = 150 * 106 / (1.732* 220* 103) = 393.7 A

Considering future expansion = 2* 393.7 A = 787 A.

Hence, the Twin ACSR Moose for the Main Bus is adequate.

CONCLUSION

These are the two important methods out of many to properly do the conductor sizing for a substation that will be able to withstand the short time current rating of the substation and future addition of load.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.