CABLE SELECTION CRITERIA

The design is based on a minimum of three factors:

Table of Contents

Short circuit current rating:

It is the most important part of the cable selection criteria. It basically is the maximum current that the cable has to handle in case of a fault until the fault isolating mechanism operates and isolates the circuit. It is expressed in KA for _sec. In substations generally, we take the value of time as 1 sec because of the operating time of relays and circuit breakers with some additional time at hand. In case we want to optimize the time, we can take just the relaying and CB operating time in the short circuit current rating. The effect of optimization shall be seen in the calculation.

CURRENT CARRYING CAPACITY

It is the rated current that the cable will be continuously conducting. In cable selection, this is a very important part that we will see in the examples below. The maximum current that a conductor can transmit directly influences the temperature of the insulation of the cable.

PERMISSIBLE VOLTAGE DROP

The voltage drop in cable selection is mainly dependent on the length of the conductor. If for the selected conductor the voltage drop is higher, we shall select the next best alternative from the manufacturer’s catalog as discussed below.

For example, the voltage drop under normal conditions for a motor load is considered 5%, whereas the permissible voltage drop in the case of starting the motor is 15%.

SELECTION OF INSULATION

We have already discussed it in detail in the previous articles. In cable selection, the insulation part plays a major role. though the thickness of insulation depends on voltage the type of insulation depends on current. For domestic use, PVC insulation holds good up to 70-degree temperature. In substations, however, we need increased current carrying capacity with maximum continuous operating temperature. The temperature and the current carrying capacity are proportional to each other. So, in the case of any power station or high-rated device, we chose XLPE insulation. The thickness of insulation depends on the conductor’s cross-sectional area and we can choose the thickness from the country’s standard.

SELECTION OF CONDUCTOR SCREEN

The conductor screen basically provides a uniform voltage distribution across the conductor length to keep the electrical field within the electrical core. Where there are a number of bends in the laying of the conductor, the screen helps to reduce the voltage stress developed in the bends. It reduces the electromagnetic interference between two different cable grades. For LT cables it is not required. It depends on the size of the conductor and hence is selected from the cable selection data sheet or standard.

Similarly, the outer sheath and armour are also selected on the basis of practiced country code and the conductor’s cross-sectional area.

Design of the conductor’s cross-sectional area

Let us make a cable selection for a 33KV feeder in a substation.

The short time current rating is 31.5 KA and the duration is 1 sec.

The cross-sectional area of the conductor is calculated by the formula

A=(Isc* √t)/k,

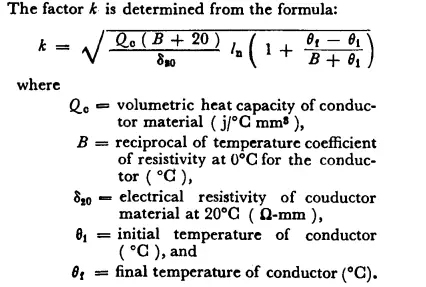

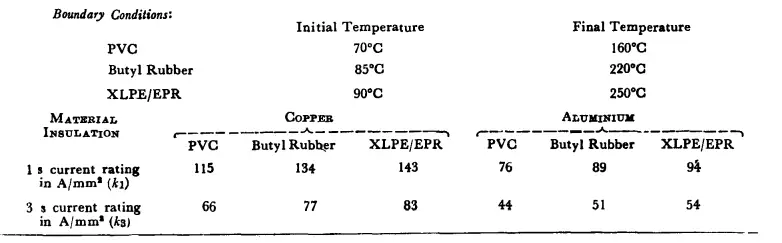

Where A is the area in mm2, Isc is the short circuit current, ‘t’ is the time duration and k is a factor that depends on the material of the protective conductor, the insulation and other parts, initial and the final temperature. We can select the value of k from IS 3043-1987 or other country standards.

The value of k from IS 3043 for aluminum conductor XLPE insulation for 1-sec duration is 94.

Therefore, A=(31.5*1000*√1)/94

=335 mm2

Now from the cable manufacturer catalog, we can see the available nominal cross-sectional area of the conductor and thus make a cable selection.

Here we can do 400 mm2 cable selection from the manufacturer’s catalogue. Since we have selected the nominal cross-section with the short circuit current therefore the derating factors are not necessary in this case.

CABLE SELECTION FOR AN HT MOTOR

Let the rating of the motor (boiler-feed-pump) be 1500 KW rated at 6.6 KV, the power factor is assumed to be 0.8,

Then current I = 1500000 / (√3 *6.6* 100 * 0.8) =164A.

Therefore, the selected cable size is 3C 240mm2 XLPE Al conductor armoured cable.

The current rating of the cable as per the catalog is 395A

Considering the derating factors,

| Derating Factor | Under ground | Air | Conduit |

| Temperature | ✔ | ✔ | ✔ |

| Grouping Factor | ✔ | ✔ | ✔ |

| Depth of laying | ✔ | * | * |

| Soil thermal resistivity | ✔ | * | * |

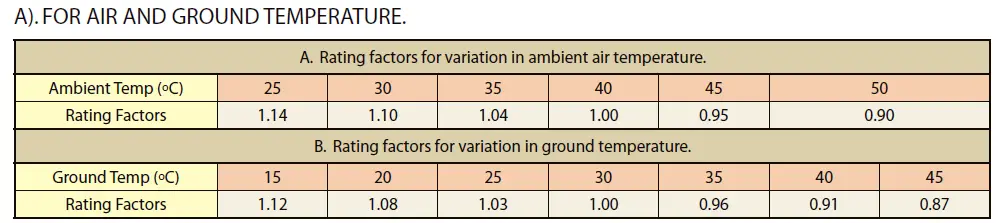

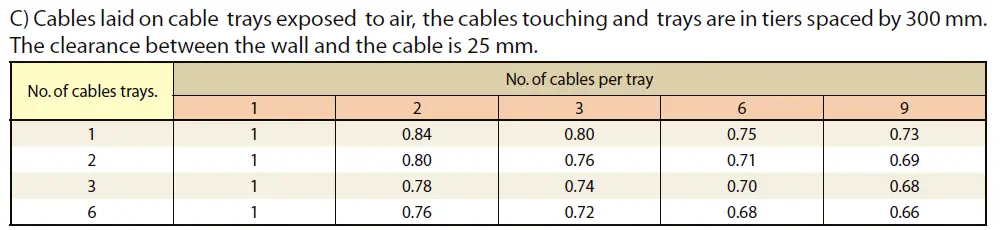

For the cables to be laid in the trench, therefore we will consider air derating factors for ambient temperature and since the cables will be laid with other cables, the thermal load of other cables will affect the cable’s rating hence, we will also consider grouping factor in the cable selection.

From the cable’s catalogue the derating factor for ambient temperature is 0.90 and for grouping factor for cables with 6 racks and 6 cables in touching configuration in each rack is 0.68.

Therefore, the overall derating factor is = 0.90 * 0.68 = 0.612.

The derated current value = 0.612 * 395 = 241.74 A.

Since the derated current, 242A per phase is more than the full load current 164A per phase.

Therefore, the selection is safe.

Voltage drop calculation:

Selected size of Cable = 3C, 240 mm2 XLPE Armour. Al conductor. Cable

Length of Cable, L = 152 m

AC Resistance of 3C, 240Sq.mm XLPE Armour. Al conductor. Cable = 0.1600 Ohms/Km

Reactance of 3C, 240Sq.mm XLPE Armour. Al conductor. Cable = 0.0870 Ohms/Km

Cos ϴ = 0.8

Sin ϴ = 0.6

Impedance of the Cable Z = Rcos ϴ + XLSin ϴ

Z = (0.16 x 0.8) + (0.087 x 0.6)

Z = 0.1802 Ohms/Km

3-ph Voltage Drop is Given by Vd = (√3 * I * Z * L) / 1000

Under Normal Running Conditions

Voltage Drop Under Normal Condition Vd = (1.732 x164 x 0.1802 x 152) / 1000

Vd = 7.78 V

% Voltage Drop is given by = (Vd x 100) / 6600

Therefore, Voltage Drop = 0.12 %

The calculated Voltage Drop of 0.12 % is less than the allowable voltage drop of 5%

Hence the selection is Safe

Under Starting Condition

Starting Current of Motor Ist = 5 IL

= 5 x 164

= 820 A

Impedance of the Cable Z = Rcos ϴ +XLSin ϴ

Where,

Cos ϴ = 0.3

Sin ϴ = 0.95

Therefore,

Z = (0.16 x 0.3) + (0.087 x 0.95)

Z = 0.131 Ohms/Km

3-Ph Voltage Drop is Given by Vd = (√3 * I * Z * L) / 1000

Voltage Drop Under Starting Condition = (1.732 x 820 x 0.131 x 152) / 1000

Vd = 16.33 V

% Voltage Drop is given by = (Vd x 100) / 6600

Therefore, Voltage Drop = 0.25 %

The calculated Voltage Drop of 0.25 % is less than the allowable voltage drop of 15%

Hence the cable selection is Safe.

CONCLUSION

Likewise, we can select the conductor’s dimension and thereby select the other parameters of the cable from the manufacturer’s catalog or from the country’s standard as in India we follow

- IS 1554 (Part-I) – 1988 Specification for PVC Insulated (Heavy duty) Electrical cables for working voltages up to and including 1100 V.

- IS 1554 (Part-II) – 1988 Specification for PVC Insulated (Heavy duty) Electrical cables for working voltages from 3.3kV up to and including 11kV.

- IS 7098 (Part-I) – 1988 Specification for Cross-Linked Polyethylene Insulated PVC Sheathed Cables for working voltages up to and including 1100 V.

- IS 7098 (Part-II) – 1988 Specification for Cross-Linked Polyethylene Insulated PVC Sheathed Cables for working voltages from 3.3kV up to and including 33kV.

- IS 3961 (Part-II) – 1967 Recommended current rating for PVC Insulated and PVC sheathed heavy-duty cables.

- IS 1255 – 1983 Code of practice for Installation and Maintenance of Power cables up to and including 33 kV rating.

This article is a part of the Cables and Conductors, where other articles related to the topic are discussed in details.