Transformer oil or mineral oil is used extensively in the transformer to provide electrical insulation between the core, windings, and the body of the transformer. The live part of the transformer, core, and winding are submerged in transformer oil that provides electrical insulation to the main tank. Transformer oil also aids in cooling as it is a media of heat transfer by convection. Apart from insulation and cooling, the transformer oil protects the internal parts of the transformer from oxidation and disintegration.

Mineral oil is used for insulating various electrical equipment but is famously called transformer oil. Because of this reason, referring to electrical quality mineral oil as transformer oil may lead to confusion. But this terminology is so commonly used in the electrical industry that veterans will find this bit funny.

Table of Contents

Functionally most electrical insulating fluids are equivalent but the chemical compositions are always not the same. While the differences normally do not defeat the objectified actions of the fluids but do affect the way of functioning.

Types of Transformer Oil

In general practice, there are mainly two types of Transformer Oil used in the power sector.

Paraffin based Transformer Oil

Paraffin-based Transformer oil is obtained from crude having a high content of naturally occurring N-paraffin wax. Paraffin oil although the oxidation rate is lower than that of Naphtha oil the oxidation product or sludge is insoluble and precipitates at the bottom of the tank and obstructs the transformer cooling system. Although paraffin-based oil has above mentioned disadvantages but still in our country it is generally used because of its easy availability.

Another problem with paraffin-based oil is its high pour point (-6 0C) due to the wax content, but this does not affect its usage due to the warm climate conditions of India.

Naphtha based Transformer Oil

Naphtha oil oxidizes more easily compared to Paraffin oil. However, the product of oxidation that is sludge in the naphtha oil is more soluble compared to the solubility in Paraffin oil. Thus, sludge in the naphtha-based oil does not precipitate in the bottom of the transformer because of the superior solubility. Hence, it does not obstruct the convection circulation of the oil, which means it does not disturb the transformer cooling system.

Properties of Transformer oil:

The essential properties of Transformer Oil are categorized as:

Dielectric strength:

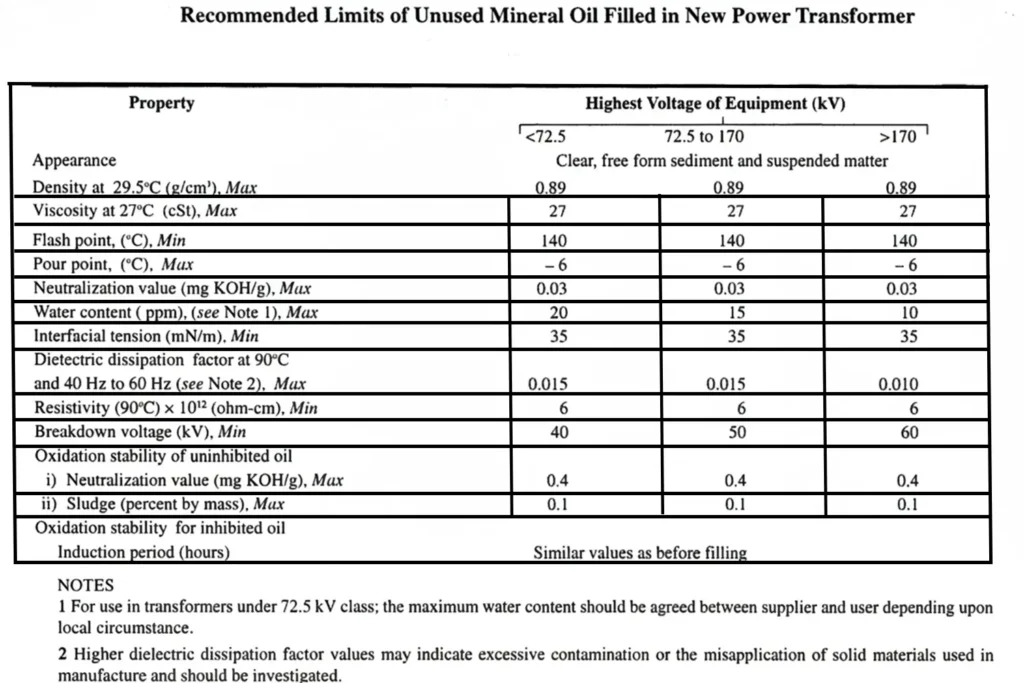

The breakdown voltage or BDV value of oil in KV is measured across a gap of 2.5mm between two electrodes. It is the minimum value of the voltage at which the oil breaks down when subjected to an electric field with a continuous increase in voltage contained in a specified apparatus.

The low value of BDV indicates contamination and the presence of water, cellulose, sludge and other conductive particles.

- The limit BDV value of new unfiltered oil is 30KV and for filtered oil is 60KV.

- For Transformers above a voltage rating of 170KV, the Limit BDV Value is 60KV pre-commissioning of the transformer and 50KV in service.

- For Transformers below a voltage rating of 170KV and above 72.5KV, the Limit BDV Value is 50KV pre-commissioning of the transformer and 40KV for the in-service transformer.

- For Transformers below a voltage rating of 72.5KV, the Limit BDV Value is 40KV pre-commissioning of the transformer and 30KV for the in-service transformer.

Specific resistance:

It is defined as the resistance offered per unit volume of oil with known voltage applied. Its unit is Ohm-cm3. It is a measure of electrical insulating property. It should be high for insulating oil. If it is low then it means free ion and conductive contaminants are present in oil. Moisture can also affect this value.

| Specimen | Specific Resistance (Ohm-cm3) |

| For New Oil | 35 * 1012 Ohm-cm3 at 900C and, 1500 * 1012 Ohm-cm3 at 270C |

| For New Transformer before commissioning | 6 * 1012 Ohm-cm3 |

| For Inservice Transformer | 0.1 * 1012 Ohm-cm3 |

Dielectric Dissipation Factor (DDF):

The dissipation factor is a measure of the quality of the oil. It is the tangent of the angle (Delta) by which the phase difference between applied voltage and resulting current deviates from 900 when the dielectric of the capacitor consists exclusively of insulating oil. It can measure dielectric loss in oil and hence the amount of energy dissipated as heat. It will be high if the oil has impurities, moisture, and aging products like acids and sludges.

Low DDF means good oil, as it indicates low dielectric losses and low level of soluble polar ionic or colloidal contaminants.

Limits:

| Specimen | Dielectric Dissipation Factor (DDF) |

| For New Oil | 0.002(max) at 900C (filtered oil) |

| For New Transformer before commissioning | Max: 0.010, for voltage rating >170 KV and, Max: 0.015, for voltage rating <170 KV |

| For Inservice Transformer | 0.2 max for V> 170 KV and, 1 max for V<170 KV |

Corrosive Sulphur:

Sulphur is very corrosive in nature. Its presence is very harmful to metallic parts.

Acidity:

The acid content in the oil plays a major part in the contamination of the oil. Highly acidic oil will trigger corrosion of metal parts, insulations will deteriorate, and sludge will form.

Limits:

| Specimen | Acidity |

| For New Oil | 0.03 mg KOH/gm (max) |

| For Inservice Transformer | 0.3 mg KOH /gm (max) |

| Total sludge content in oil | Max 0.1% |

Water content:

It must be low. If high it affects BDV value and affects the insulation of windings. The test is carried out using automatic coulometric titration and expressed in PPM. Water is soluble in transformer oil and its solubility ranges from 30-80 PPM at 20 degrees Celsius. The solubility is higher at higher temperatures. Though water has a little detrimental effect on transformer oil, the paper insulation has a great affinity for the water. The main objective is therefore to strive for low moisture content in oil for limiting the water in the paper insulation.

Appearance:

If clear and transparent then there are no suspended matters and sediments. If the colour of the oil is clear and pale yellow then it’s good, If it’s bright Yellow then ok, if amber brown it means the start of deterioration and sludge formation, if it’s green then it’s dissolved copper or metallic contaminants. If the smell is bad then investigate and replace the oil.

Density:

It is mass per unit volume. Higher density also means higher viscosity which will reduce the oil flow and hence affect heat dissipation.

Oil density for electrical insulation should not be more than 0.89g/cm3.

Viscosity:

It is basically the resistance to flow. Higher viscosity means higher resistance to flow, hence low value is preferred for the higher rate of heat transfer standard value is 27centi stoke.

Pour point:

Temperature at which oil begins to solidify or in other words, the lowest temperature at which the oil flows. It is essential for cold weather applications. The standard value is -60C

Flashpoint:

It is the minimum temperature at which oil when heated gives off enough vapour to form flashes of flames. This test assumes significance after an arcing fault inside of a transformer.

If the flash point is low it will induce fire risks. It can reveal the presence of volatile and flammable materials in oil.

Interfacial tension:

It is the surface tension between two fluids. It is a good indicator of oil quality and it should be high. Low IFT indicates sludges and deterioration. IFT helps in determining polar contamination.

Limits:

| Specimen | Interfacial tension |

| For New Oil | 0.040 N/m |

| New Transformer before commissioning | 0.035 N/m |

| For Inservice Transformer | 0.015N/m |

Standard values:

Ideal Transformer Oil

ldeal Transformer oil must have low density and low viscosity for better heat transfer. Low pour point to avoid solidification. High flash point for fire resistance. High BDV for high voltage application. High Resistivity for better insulation resistance. Good arc quenching properties and lastly should be Non-toxic.

This article is a part of the Transformer page, where other articles related to the topic are discussed in details.