Buchholz relay is a mechanical, gas-actuated device that utilizes mercury switches to initiate alarm and trip signals on the occurrence of incipient faults inside an oil-filled transformer. It may be noted that these relays are installed on transformers above 750KVA capacity. Incipient faults are those faults that are slowly developing.

Table of Contents

Buchholz relays have two types of contacts one is utilized for alarm and the other for tripping. In the event of a severe internal fault, the Buchholz relay can instantly interrupt the transformer from the supply.

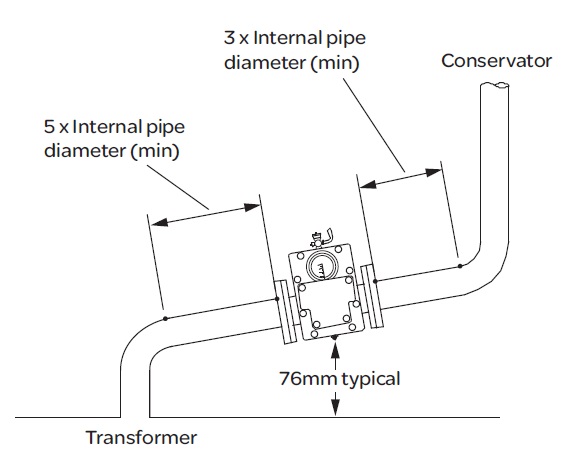

They are installed in the pipe that connects the main tank of the transformer to the conservator. The angle of inclination of the pipe is ideally at 7-9 degrees with the horizon. This is because if it’s fully vertical, the flow of oil will not be laminar and if the angle is too large then gas bubbles will cling to the pipe instead of going to the Buchholz housing or towards the conservator.

Formation of sludges is also a possibility that cannot be ignored. For this reason, 7-9 degrees is optimal for the best operation of this relay. The pipe approaching the relay from the main tank should be straight and should be 5 times the pipe’s diameter and the one leaving the relay towards the conservator must be at least 3 times the pipe’s diameter.

It can also be used in choke coils having a conservator for providing desired protection.

This relay responds to the accumulation of gas or air inside the apparatus when the oil level is low or due to an incipient fault. It also responds to the high flow rate of oil that is oil surge in the chamber. The relay either gives an alarm or disconnects the endangered equipment. Buchholz relay operates on very slight faults which are in the process of developing. So that greater damage to the equipment can be prevented.

TYPES OF FAULTS:

It is because of some faults, the alarm circuit operates while for major faults, the trip circuit operates. Among them, the important ones are noted below.

The alarm circuit operates when a specified volume of gas gets collected in the relay housing because of the following faults.

- If there is a partial discharge between the live part and the tank or core of the transformer.

- Insulation failure in the core bolt.

- Laminations are shorted.

- Poor electric contact.

- Air can get inside the transformer because of the circulating pumps.

- Transformer over-heating.

Operation of the trip circuit by an oil surge in the event of more serious faults such as

- Internal earth fault.

- Shortcircuit in the winding of the transformer.

- Internal phase-to-phase faults.

- Increased oil flow due to leakage from the tank, radiator, and tubes.

- Bushing puncture.

The color, odor, and chemical composition of the gas formed and collected near the body of the relay can give out the nature and type of the fault.

| NATURE OF GAS | TYPE OF FAULT (Inffered) |

| If the gas lacks any color and odor or only a faint odor of oil is present. | Trapped air in the oil or insulation. |

| If the gas is grey with a sharp odor, non-inflammable. | Overhead or faulty insulation. |

| If the gas is yellowish and inflammable | Surface leakage. |

| If the gas is dark grey and inflammable | Flashover or excessive heating of oil caused by a fault in the core or winding. |

| If the gas is black | Free arc in the oil |

CONSTRUCTION OF BUCHHOLZ RELAY

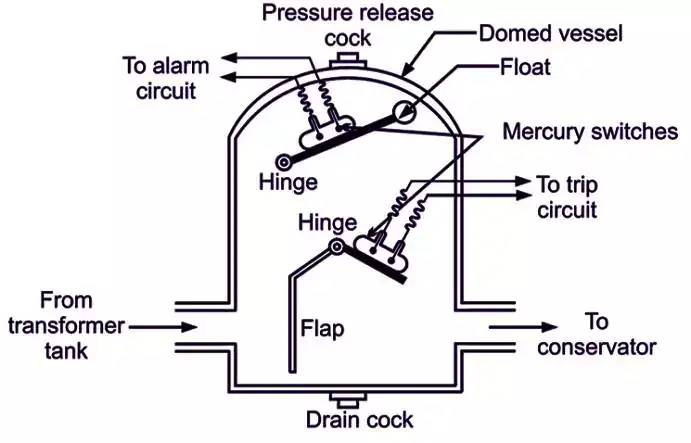

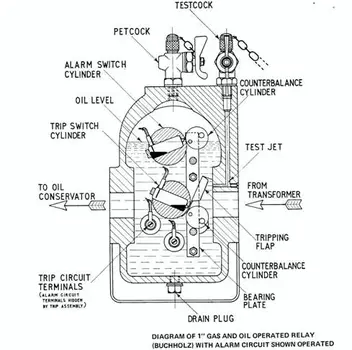

The Buchholz relay is a dome-shaped vessel that is connected to the pipe that connects the main tank and conservator. The housing is mainly an oil-tight fabrication. It houses the alarm and tripping element consisting of two buckets hinged on a frame, one in the upper part and one in the lower, both consisting of a flap.

The flanges on the body allow easy connection of the relay to the connecting tubes/ pipes. The relay has wide inspection windows graduated with scale to show the volume of gas accumulated inside the relay.

A drain screw is located in the lower part of the body to drain the oil.

The upper alarm and the lower trip bucket are provided with a mercury switch. Mercury being a metal can conduct electricity and it is liquid at normal temperatures hence when the flap operates flow of mercury conducts electricity from one contact to another thereby making it normally open contact to closed. When the relay is filled with oil, the switches are affected by the buoyancy of the oil. Counterweights are placed to mitigate these effects as they add to the moment.

It may be noted that moment is equal to force multiplied by perpendicular distance.

The termination of these mercury switches is housed in a terminal box with two terminals for alarm and two for tripping.

There is a test cock at the upper side through which the decomposed gas can be collected for testing.

WORKING PRINCIPLE OF BUCHHOLZ RELAY

All faults inside a transformer using oil as an insulating medium, except those due to airlock and oil leakage are consequences of local overheating and arcing. This overheat decomposes the insulating oil and it forms gases. The rate of gas formation is dependent on the nature of the fault and its severity, its effect produced in the relay varies accordingly.

For incipient faults, slow-developing gas bubbles accumulate in the upper part of the relay housing, which is a gas chamber. The Buchholz relay is connected to the pipe between the main tank and the conservator through which the rising gasses and air passes and gets trapped inside the relay.

Under normal operating conditions, the relay is filled with oil. As gas starts to accumulate in the relay, the accumulated gas starts to replace the oil from it. As the oil level falls in the relay, it causes the mercury switch to tilt. This tilt in the mercury switch either makes or breaks the contact.

In case of a serious fault that generates large heat, violent gas formation starts in the main tank, and pressure waves are set up in the oil forcing it to flow towards the conservator’s vessel. As the flow rate of the oil exceeds the adjusted sensitivity in the operating vane of the relay which is coupled with the mercury switch, the switch gets tilted by the pressure of the oil thus generating the tripping command to the circuit breaker thus disconnecting the equipment from supply.

The float and the mercury switch are connected to each other so that the tilt in float causes the switch to contact the making position.

The setting range of the operating vane for flow rate of oil is from 50 to 150 c.m/sec oil flow. It is usually set at 100cm/sec.

Reduced the oil level inside the conservator until it is empty without oil pressure, the oil inside the body of the relay flows out and causes the rotation of the buckets, setting in action the alarm contacts first and the trip contact successively.

Penetration of air inside the tank happens due to the bad working of the forced oil circulation pumps. It has the same effect as the small failures. Small bubbles of air, which accumulate on the top part of the relay, set the alarm contact in action.

TYPES OF BUCHHOLZ RELAY

SINGLE FLOAT TYPE BUCHHOLZ RELAY

In the single-float Buchholz relay, the operating vane and the float form a single unit. The mercury switches connected to the floats can either operate an alarm or trip the endangered apparatus altogether. The choice depends upon the installation. That is why, small transformers in unattended substations are best provided with the single-float relays, and the transformers simply get disconnected when a fault occurs. The single float relay can also be used for alarm purposes.

DOUBLE FLOAT TYPE BUCHHOLZ RELAY

The double-float Buchholz relay can be supplied for any type of transformer and it is usually found advisable to use the upper float for an alarm. This float responds to the accumulation of gas or air and low oil levels. The lower mercury switch, on the other hand, is used to trip the apparatus or transformer, since it responds to oil loss via the float and to pressure waves via the opening vane. It is, however, possible, by means of a locking device, to cancel the response of the lower float when the oil level sinks so that tripping will not take place on account of this fault. However, it is not recommended.

INSPECTION BEFORE COMMISSIONING

A system is provided in the Buchholz Relay for testing of the alarm and trip switching system. The details of the testing are as follows.

Testing continuity of Mercury switches:

Firstly, we have to loosen the nut on the Test Key. Rotation of the key in the anticlockwise direction till the slot on the Test Key points toward the the symbol T/L (Transit/Lock) position. Both the up-switch alarm and bottom-switch trip shall show continuity.

While the clockwise rotation of the Test Key to S (service) position, will break the continuity. The circuits will therefore get actuated in the ‘ON’ position only on the occurence of an internal fault in the transformer.

Testing of Alarm Circuit:

- Buchholz relay has a gas release cock on the top, through which the collection of accumulated gas for further analysis can be done by screwing a test bottle to the test cock and opening the test cock for gas collection.

- For checking the operation of the alarm circuit we have to screw a test pump to the test cock. By opening the cock, and pumping air slowly inside the relay until the upper switch operates the alarm.

Testing of Trip Circuit:

- At the top of the relay, a test valve is mounted for checking the tripping circuit operation by means of high pressure air.

- By openning the test valve, we can let the test pump release pressurised air, which then by impinging on the flaps will operate the lower trip switch.

CONCLUSION:

To conclude it can be said that a protective relay does not indicate the appearance of the fault. It operates when the fault occurs but the Buchholz relay gives an indication of the fault at a very early stage, by anticipating the fault and operating the alarm circuit. It is recommended to put the transformer out of service for thorough inspection before charging again.

Buchholz relay is the simplest protection in the case of transformers and is the most economical one also.

FAQ’s

Which gas is produced in the Buchholz relay?

No gas is produced in the Buchholz relay. However, the Buchholz relay detects gasses that are byproducts of transformer oil heating because of faults like carbon monoxide, carbon dioxide, hydrogen, etc.

Why is mercury used in Buchholz relays?

Mercury being a liquid metal at normal temperature and pressure, it can make the contacts conductive on the tilt of switches, generated by the gas pressure. Another reason is that the mercury is more cohesive and it will either break or make the electrical contacts without any intermediate state.

What is another name for a Buchholz relay?

Another name for the Buchholz relay is the gas detector relay.

What is the ANSI code of the Buchholz relay?

The ANSI code for the Buchholz relay is 63.

This article is a part of the Protection System, where other articles related to the protection of electrical equipments are discussed in details.